Types of Bearings: A Comprehensive Guide

CONTENTS

- Importance of bearings in Mechanical Systems

- What is the Purpose of Bearings?

- Exploring the Different Types of Ball Bearings

- Understanding the Different Types of Roller Bearings

- All About Slewing Ring Bearings and Their Different Types

- All About Cam Followers and Their Different Types

- All About Plain Bearings and Their Different Types

- All About Linear Bearings and Their Different Types

- All About Mounted Bearings and Their Different Types

Importance of bearings in Mechanical Systems

Bearings are crucial for smooth and efficient motion in mechanical systems, while reducing friction, wear, and noise. There are various types of bearings, including ball bearings, roller bearings, Slewing Ring Bearings, etc. This guide will explore different types of bearings(see the below figure), their working principles, advantages and disadvantages, common applications, and best practices for selection and maintenance.

What is the Purpose of Bearings?

The primary purpose of bearings is to support loads with minimal friction and wear, ensuring efficient motion, reducing energy consumption, and providing stability, precision, and reliability to mechanical systems while minimizing noise and vibration.

Benefits of Using Bearings in Mechanical Systems

- Reduction of friction and wear

- Facilitation of smooth and efficient motion

- Support of heavy loads and shock loads

- Minimization of noise and vibration

Types of Mechanical Systems that Use Bearings

- Automotive and transportation

- Aerospace and aviation

- Industrial machinery and equipment

- Consumer products such as household appliances, bicycles, and roller skates, etc.

Common Bearing Design Features

- Inner and outer rings

- Rolling elements (balls or rollers)

- Cage or retainer to keep the rolling elements spaced evenly

- Seal or shield to protect against contaminants

Exploring the Different Types of Ball Bearings

Ball bearings use rolling balls to reduce friction and can handle radial or thrust loads. They have a compact design, require minimal lubrication, and are cost-effective. However, these types of bearings have limited load capacity, are sensitive to misalignment and contamination, and can be noisy. They are used in electric motors, automotive wheels, machinery, aerospace, and household appliances.

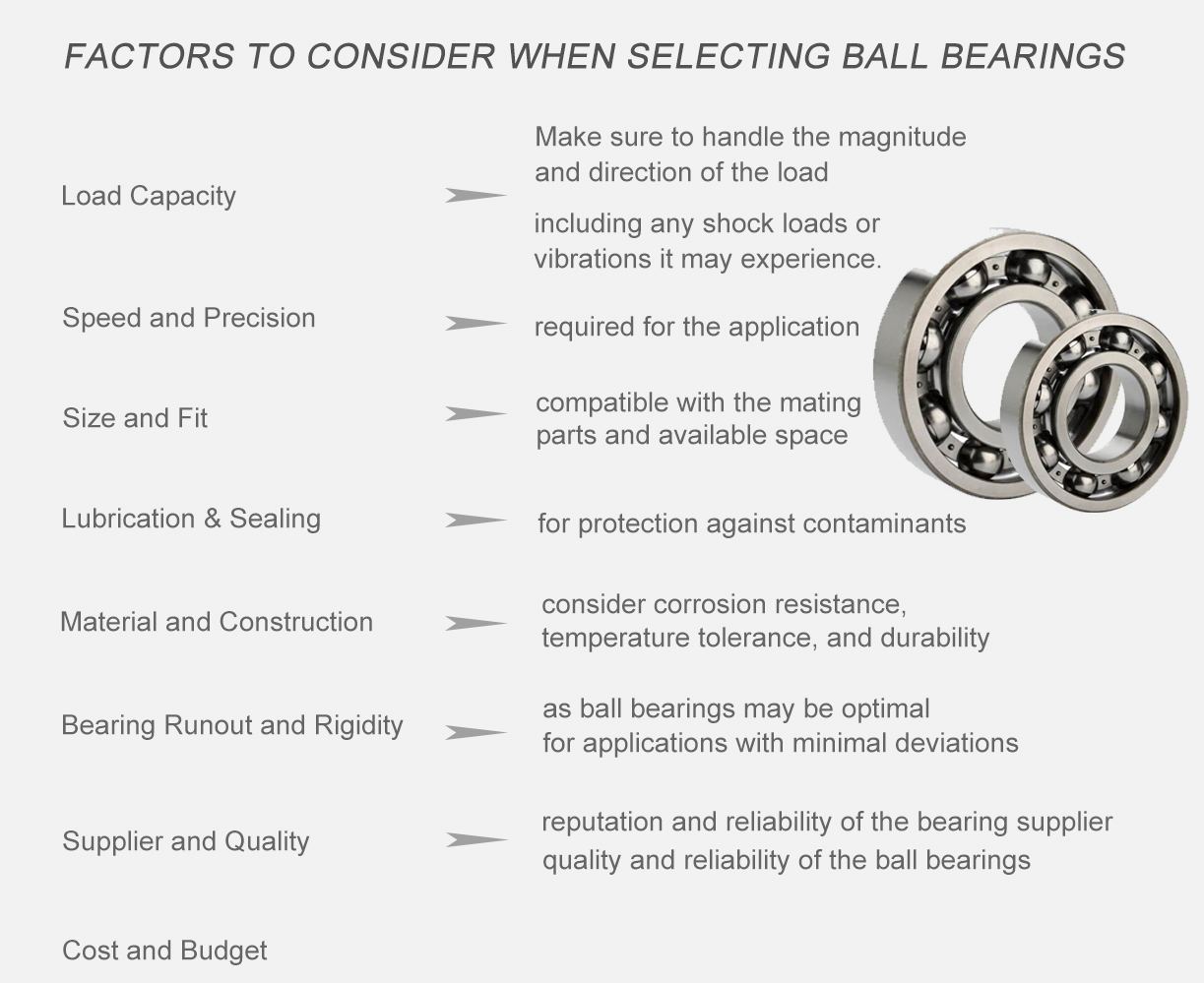

How to Choose the Right Ball Bearing

When choosing ball bearings, it's essential to consider factors (see the figure below) such as load capacity, speed and precision requirements, size and fit compatibility, lubrication and sealing needs, tolerance for runout and rigidity, material and construction suitability for the environment, etc. For more details, please refer to the figure below.

Types of ball bearings:

Miniature Bearings offer high precision and reliability, low noise and vibration levels, reduced

weight and friction, and improved energy efficiency. They are ideal for limited space or high-speed

applications, and can handle both radial and axial loads.

Thin Section Bearings offer advantages such as a smaller cross-section, reduced weight, higher

Thin Section Bearings offer advantages such as a smaller cross-section, reduced weight, higher

precision, lower torque and friction, and high-speed capabilities, making them ideal for space-limited,

weight-sensitive, and high-speed applications with improved efficiency and energy consumption.

Flanged Bearings have a flange on the outer ring that simplifies mounting onto a shaft or housing.

Flanged Bearings have a flange on the outer ring that simplifies mounting onto a shaft or housing.

They are suitable for applications with limited space or where a stationary component is required, and

they can handle both radial and axial loads.

Self-aligning Ball Bearings have a continuous spherical outer ring raceway, allowing the inner ring and ball

Self-aligning Ball Bearings have a continuous spherical outer ring raceway, allowing the inner ring and ball

complement to swivel for self-alignment. They absorb radial forces, making them ideal for applications with shaft

and housing misalignment, and feature a double row of balls guided by a cage and inner ring raceway.

Angular Contact Ball Bearings are ideal for combined loads as their specific contact angle enables the

Angular Contact Ball Bearings are ideal for combined loads as their specific contact angle enables the

transfer of forces between the two raceways. They are suitable for diverse industrial applications that demand

precise and high-performance operation, particularly for transferring high axial and radial forces.

Deep Groove Ball Bearings are highly versatile, with a capacity for high radial and axial loads, low friction,

Deep Groove Ball Bearings are highly versatile, with a capacity for high radial and axial loads, low friction,

and high-speed operation. They have a simple design that makes them easy to maintain and suitable for various

applications. These types of bearings have low torque, making them ideal for high-speed operations.

Thrust Ball Bearings are types of bearings that handle axial loads in one or both directions with high-speed

Thrust Ball Bearings are types of bearings that handle axial loads in one or both directions with high-speed

capabilities. They offer low friction, high precision, and compact design for easy installation and maintenance,

often used with other bearings to support rotating machinery.

Understanding the Different Types of Roller Bearings

Roller bearings utilize cylindrical, tapered, spherical, or needle-shaped rollers to evenly distribute loads, reducing stress and friction for smooth motion. Advantages include high load capacity, improved efficiency, rigidity, accuracy, low vibrations, easy maintenance, and axial displacement adjustment. Disadvantages include higher cost and noise. These types of bearings are used in automotive, industrial, aerospace, construction, energy, railway, marine, etc.

How to Choose the Right Roller Bearing

When choosing the right roller bearing, consider factors such as load capacity, speed requirements, operating conditions, mounting and installation, and budget. Here are some common roller bearing types.

Tapered roller bearings utilize tapered rollers to handle both radial and axial loads, providing

Tapered roller bearings utilize tapered rollers to handle both radial and axial loads, providing

high load capacity and efficient transfer of forces. They are widely used in various industries and

offer reliable performance and durability.

Cylindrical roller bearings use cylindrical rollers to provide high radial load capacity and good

Cylindrical roller bearings use cylindrical rollers to provide high radial load capacity and good

rigidity. They are widely used in different industries and offer reliable performance, long service

life, and low friction.

Spherical roller bearings feature barrel-shaped rollers arranged in two rows, offering high radial

Spherical roller bearings feature barrel-shaped rollers arranged in two rows, offering high radial

load capacity and the ability to accommodate misalignment. They are utilized in various heavy-duty

applications and offer excellent durability and performance.

Needle roller bearings use thin, cylindrical rollers that are longer than their diameter to provide

Needle roller bearings use thin, cylindrical rollers that are longer than their diameter to provide

high radial load capacity in tight spaces. They are widely used in various industries and offer

excellent performance, reliability, and space-saving design.

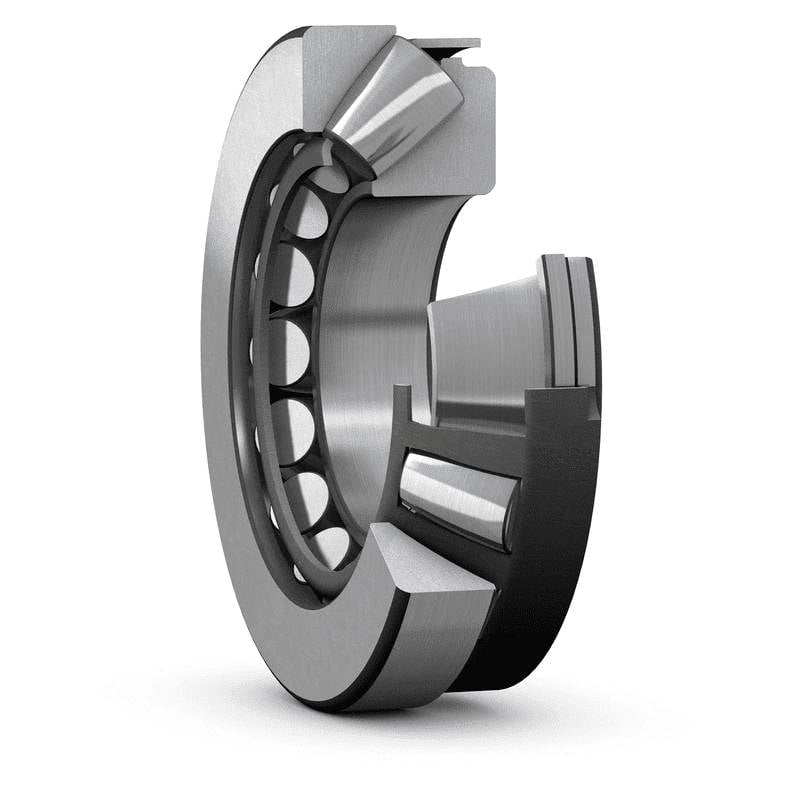

Spherical roller thrust bearings use asymmetrical barrel-shaped rollers that can handle high axial

Spherical roller thrust bearings use asymmetrical barrel-shaped rollers that can handle high axial

loads and misalignment. They are widely utilized in various heavy-duty applications and offer excellent

performance, durability, and load-carrying capacity.

Cross roller bearings utilize cylindrical rollers arranged in a cross pattern to offer high radial and

Cross roller bearings utilize cylindrical rollers arranged in a cross pattern to offer high radial and

axial load capacity with low friction. They are widely used in different industries and offer precise

motion control, compact design, and reliable performance.

Maintain these types of bearings with proper lubrication, regular inspection, correct handling, avoidance of overload and misalignment, and clean environment.

All About Slewing Ring Bearings and Their Different Types

Slewing ring bearings support heavy loads and ensure efficient load transfer and smooth rotation. They have advantages like high load-bearing capability, versatility, customizability, space-saving design, and smooth rotation. However, they come with higher cost, complex installation, heavy weight, misalignment sensitivity, and regular maintenance requirements.

Slewing bearings offer a wide variety of solutions for the most demanding specifications in a variety of applications, including Heavy equipment, Aerospace and defense, Robotics, Renewable energy, Medical systems, etc.

How to Choose the Right Slewing Ring Bearings

Select slewing ring bearings based on load capacity, stiffness, operating conditions, mounting, gear requirements, and maintenance.

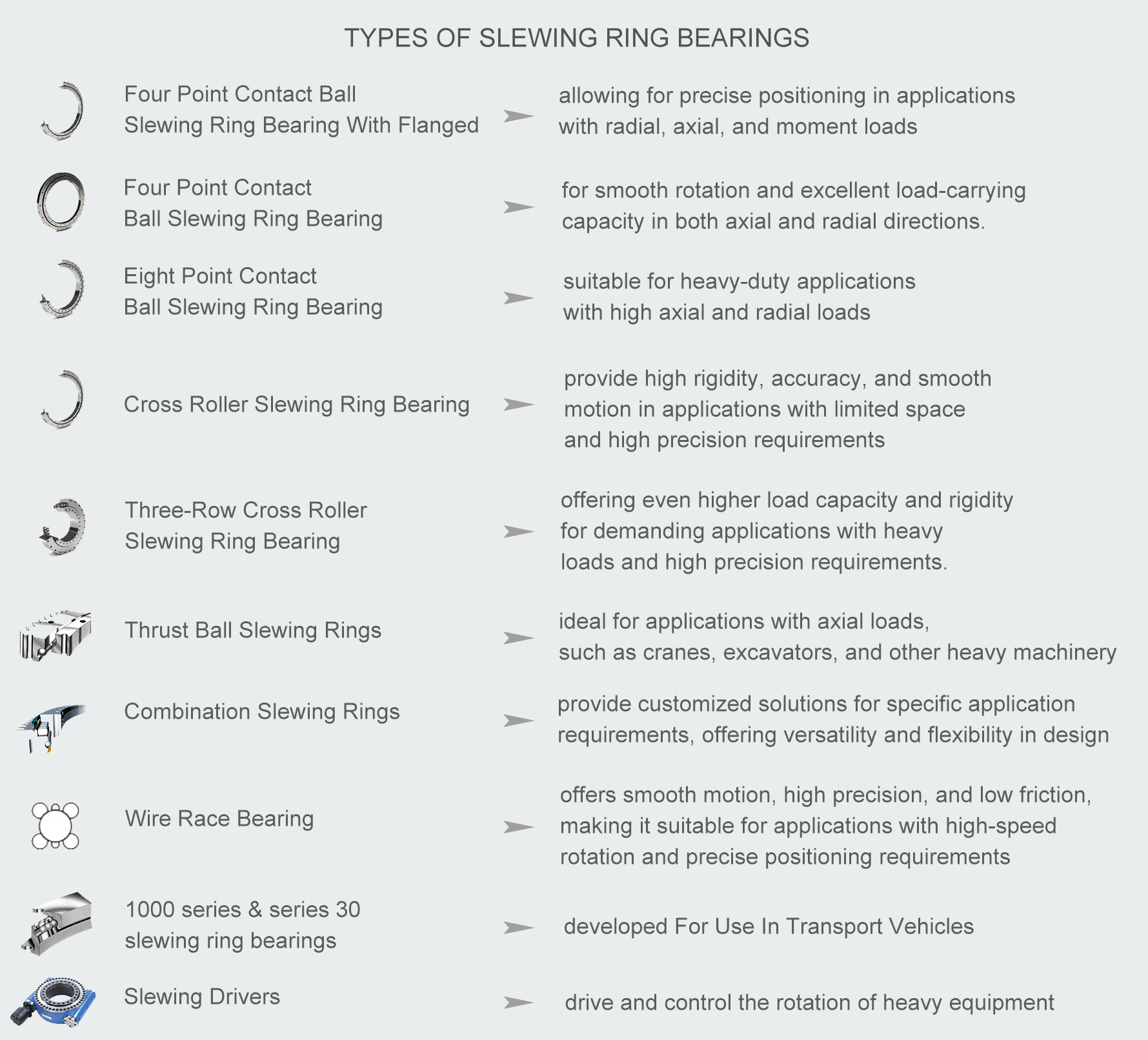

Types of slewing ring bearings include ball slewing bearings, Roller Slewing Ring Bearings, Combination Slewing Ring Bearings, Thrust Ball Slewing Rings, wire race bearing, etc. Some are standardized and some with flanged. Gears for these slewing bearings include external gears and internal gears and some without any gears.

For more details of these types of bearings and their features, refer to the following picture.

Best practices for maintaining types of slewing ring bearings include regular inspection, proper lubrication, correct handling and installation, avoiding overload and misalignment, keeping the environment clean, and following manufacturer's guidelines.

All About Cam Followers and Their Different Types

Cam followers are types of bearings that follow a cam lobe profile to transmit motion and load between machine parts. Despite offering high load capacity, they have limitations in high-speed or high-precision applications and require more maintenance. These types of bearing are widely used in machinery, aerospace, food processing, etc. Consider their pros and cons before choosing.

How to Choose the Right Cam Followers

When selecting cam followers, you have to consider factors such as load capacity, operating conditions, cam profile, bearing type, lubrication, mounting and installation, cost-effectiveness, and manufacturer reputation.

Two main types of cam followers:

- Stud-type cam followers: types of bearings which have a stud that attaches to a mating part and can handle both radial and axial loads.

- Yoke-type cam followers: types of bearings which have a yoke or arm that allows for easy attachment to a shaft or pin and are suitable for heavy radial loads.

To well maintain cam followers, you have to inspect for wear/damage, ensure proper mounting and alignment, avoid overloading, monitor operating conditions, follow manufacturer's lubrication recommendations, and choose quality followers from reputable manufacturers.

All About Plain Bearings and Their Different Types

Plain bearings are types of bearings which minimize wear and friction between two surfaces using low-friction materials and lubrication. Advantages include simple design, self-lubrication, and heavy load handling. Disadvantages include higher friction, wear over time, and maintenance requirements. Used in various industries such as automotive, aerospace, and power generation for low-friction sliding or rotational motion.

How to Choose the Right Plain Bearings

When choosing plain bearings, you have to consider the load capacity, operating conditions, bearing type, material selection, lubrication, clearance, installation and alignment, etc.

Types of Plain Bearings include:

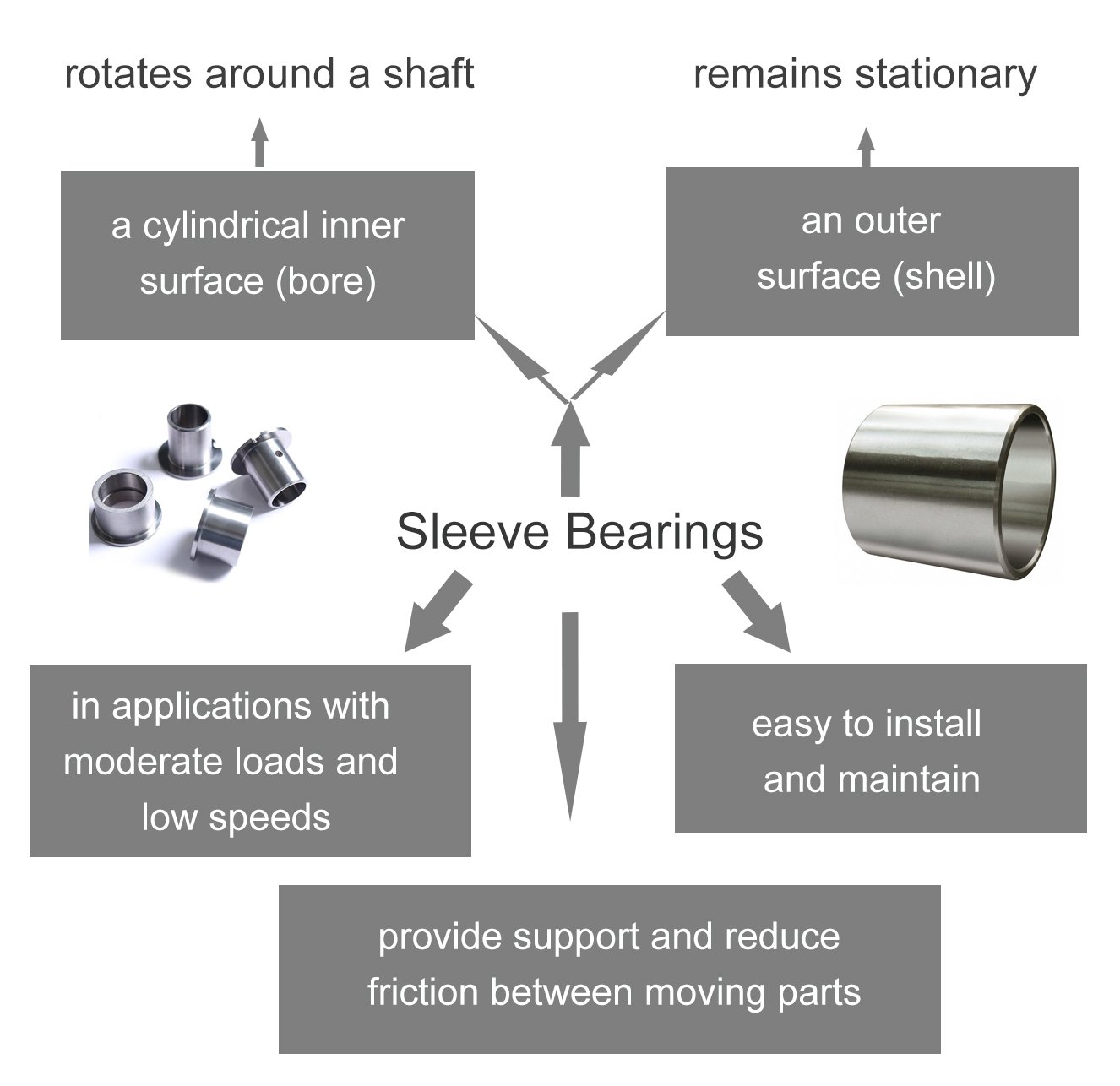

- Sleeve Bearings: types of bearings that are Cylindrical bearings with simple design and can reduce friction between moving parts.

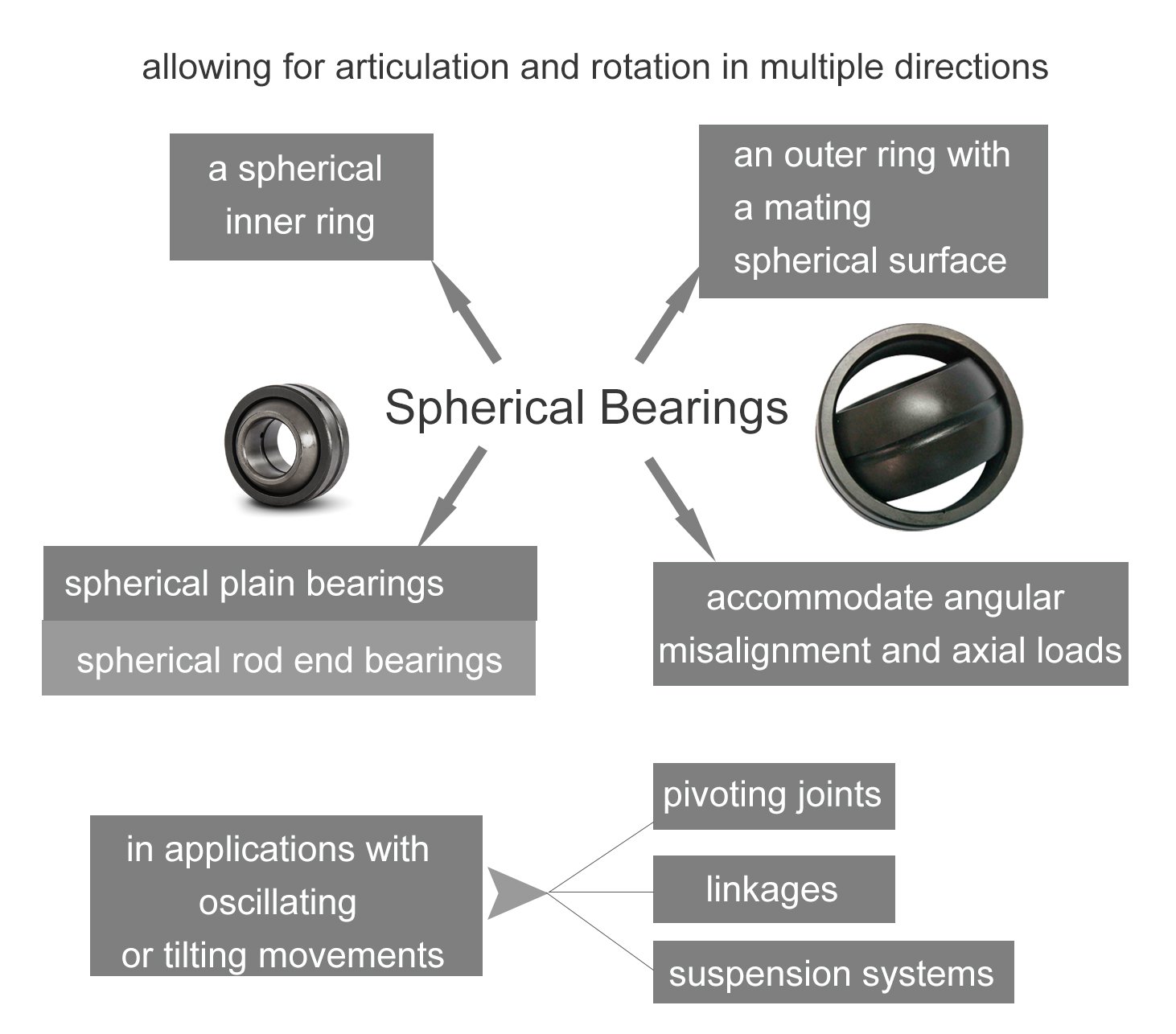

- Spherical Bearings: types of bearings with Ball-shaped inner ring, concave outer ring, used in oscillating or tilting movements.

To maintain plain bearings, it is recommended to lubricate them regularly, ensure cleanliness, proper alignment and clearance, control temperature, inspect for wear and damage, replace worn-out bearings promptly, and follow the manufacturer's guidelines.

All About Linear Bearings and Their Different Types

Linear bearings are types of bearings which enable smooth and precise linear motion using a carriage with a rolling element that moves along a rail or track. Advantages include high precision, low-friction motion, and long service life. Disadvantages include higher cost and sensitivity to dirt, debris, and potential noise or vibration. They are widely used in CNC machines, industrial automation, medical equipment, and printing and packaging machinery.

How to Choose the Right Linear Bearings

When choosing linear bearings, consider factors such as load capacity, operating conditions, bearing type, material selection, lubrication, clearance, installation, cost-effectiveness, and manufacturer reputation for reliable and efficient linear motion.

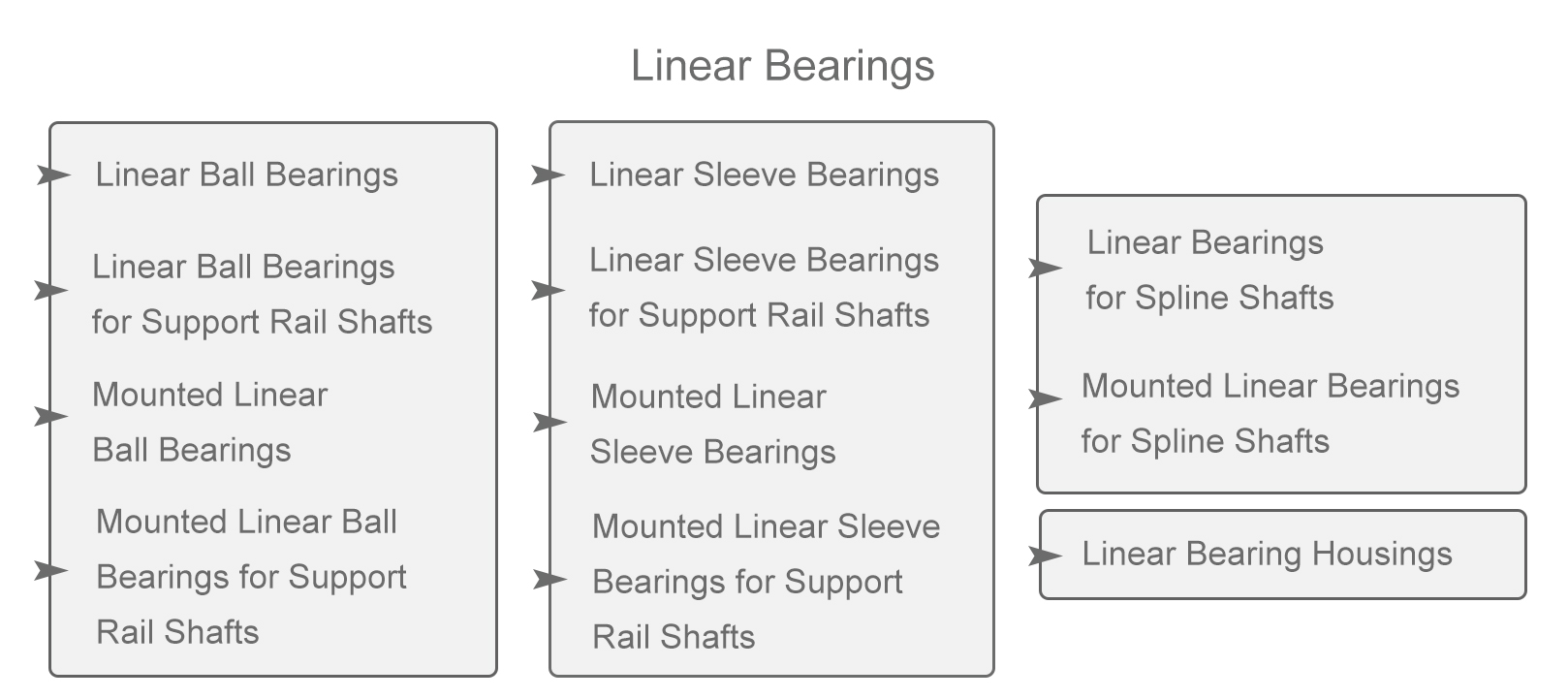

Types of Linear Bearings:

- Linear Ball Bearings: types of bearings with smooth linear motion, high precision, and load-carrying capacity.

- Linear Sleeve Bearings: types of bearings with low friction, low noise, suitable for light-duty applications.

- Mounted Linear Bearings: types of bearings with Easy installation, versatile for various linear motion applications.

See the figure for a detailed classification of linear bearings.

To maintain linear bearings, you have to do regular lubrication, keeping clean, proper clearance and alignment, monitoring for wear and damage, prompt replacement of worn-out bearings, following manufacturer's recommendations, providing training for personnel, and consulting with experts for specific maintenance requirements, etc.

All About Mounted Bearings and Their Different Types

Mounted bearings are pre-assembled units that reduce friction and wear, supporting rotating shafts in stationary housings. These types of bearings offer easy installation, versatility, and reduced maintenance, but have higher initial cost, potential for misalignment, and limitations in high-speed or high-precision applications. They are widely used in various industries such as conveyors, HVAC systems, food processing, packaging, agriculture, mining, construction, etc.

How to Choose the Right Mounted Bearings

When selecting mounted bearings, consider load capacity, operating conditions, types of bearings, material, lubrication, clearance, tolerances, cost-effectiveness, manufacturer reputation, and ease of mounting.

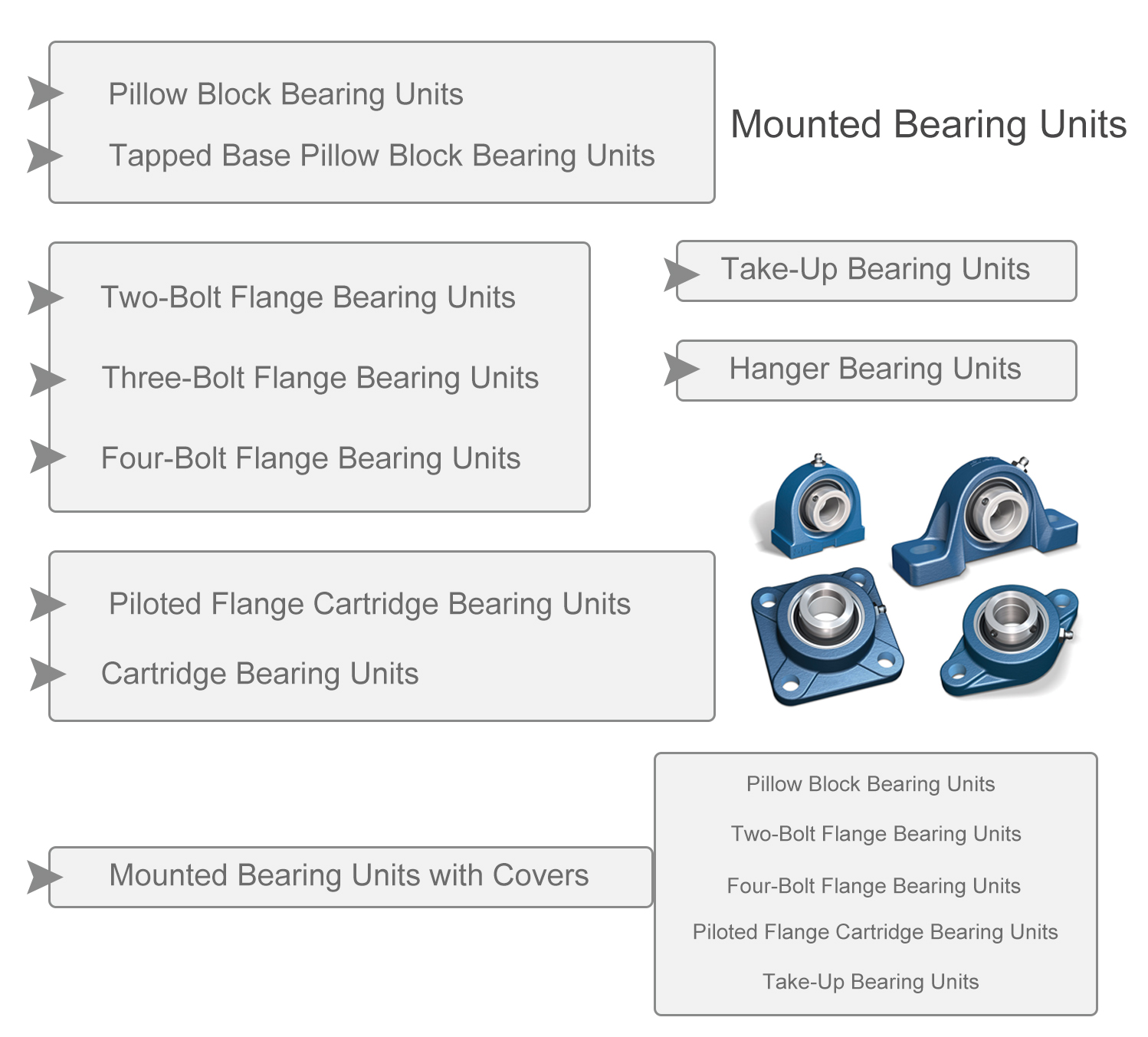

Types of mounted bearings:

- Pillow Block Bearings: types of bearings that is Easy-to-install bearing units for various applications.

- Flange Bearings: types of bearings with flanged housing for tight spaces or specialized mounting.

- Take-Up Bearings: Adjustable mounted types of bearings for belt drives and conveyor systems.

- Hanger Bearings: Suspended types of bearings for overhead support of rotating shafts.

- Cartridge Bearings: Self-contained, replaceable bearing units for high uptime applications.

For more details of these types of bearings, please see the figure below.

To maintain mounted bearings, follow best practices such as regular lubrication, proper cleaning, alignment, temperature monitoring, inspection for wear and damage, prompt replacement of worn-out bearings, training personnel, following manufacturer's recommendations, and consulting experts for specific maintenance requirements.

Summary of Types of Bearings and Final Thoughts

Bearings are vital for supporting motion, heavy loads, and reducing friction, wear, noise, and vibration. Types of bearings include ball, roller, plain, and linear, each with their own pros and cons. Choosing the right bearing based on load capacity, speed, environment, temperature, and maintenance is crucial for optimal performance and reliability. Proper maintenance, including lubrication and wear monitoring, is essential for extending lifespan. Seek guidance from experts in selecting and maintaining the right types of bearings.

Keep Learning