Custom Bearings

Custom bearings are absolutely vital for applications that require specific designs and enhanced performance. At LILY Bearing, our expertise in custom bearing design helps us meet the unique needs of every client, while providing high performance and reliable bearing materials across many industries.

Learn more about our collaborative custom design approach and how we ensure each bearing we manufacture is fully optimized for its intended use.

Request a Quote Today

What are Custom Bearings?

Custom bearings are bearings that are specifically designed to meet the requirements that most standard bearings simply can’t fulfill. Unlike typical bearings, our custom options are specifically tailored for your needs through a comprehensive customization process. Our goal is always to provide you with a product that performs well, lasts long, and meets your exact specifications.

Generally, customization involves a highly detailed bearing design process, where we determine the size, materials, precision, and lubrication needed for your application.

LILY Bearing’s Custom Design Capabilities

At LILY Bearing, we have more than two decades of experience and extensive design capabilities that help us cater to diverse application needs.

Custom Precision

An improperly sized bearing can cause project delays, damage, and a lot of headaches. As such, applications that demand exact tolerances and smoother operation require precision. Even the slightest deviation can have a massive effect on performance and costs. That’s why our services are trusted by clients in the medical, aerospace, and transportation industries.

Custom Lubrication

Proper lubrication is crucial for many applications where reduced friction and increased longevity are needed. Depending on your needs (i.e., temperature, speeds, climate, etc.), we may also recommend additional methods of lubrication. Not only does this ensure your bearings operate efficiently, but it also helps to maintain their performance for years to come. We also handle custom bearing designs that require specialized greases, coatings, and other specific lubrication needs.

Types of Custom Bearings

With our level of experience and expertise, LILY Bearing is able to provide various types of custom bearings to meet your specific configuration needs:

- ● Ball Bearings

- Excellent for radial and axial loads.

- ● Roller Bearings

- Better for heavy-duty applications.

- ● Slewing Ring Bearings

- Often used in large machinery and robotics.

- ● Turntable Bearings

- Mainly for rotational applications.

- ● Thin Bearings

- For compact spaces that require absolute precision.

- ● Miniature Bearings with Flanges

- Perfect for high-precision, small-scale applications.

- ● Thrust Bearings

- Ideal for handling axial loads in high-pressure applications.

Advantages of Custom Bearings

Opting for custom bearings offers several benefits:

Performance Optimization

Because custom bearings are designed to meet such exact requirements, they lead to improved efficiency, smoother operation, and the ability to handle unique operational conditions.

Longevity

The custom bearings we design are built to last. Tailoring the materials and design to your application increases durability and reduces the frequency of replacements. That means it’s more cost effective and efficient for you.

Reliability

A precise design ensures that each bearing meets the exact specifications of your application. This translates to consistent performance, minimizing the risk of unexpected failures and enhancing the overall dependability of your equipment.

High-Load Capacity

Custom bearings are engineered to support specific load requirements, whether they involve radial, axial, or combined loads. This capability ensures optimal performance even under heavy-duty conditions, providing the necessary support for demanding applications.

Corrosion Resistance

Custom bearings can be manufactured using materials like stainless steel and ceramics, which offer superior resistance to corrosion. This feature is particularly important in environments exposed to moisture, chemicals, or extreme temperatures, extending the lifespan of the bearings and maintaining their performance.

Custom Material

We offer a variety of materials to meet your needs. Those materials include, but are not limited to:

- ● 52100 Steel

- Best known for its hardness and resistance to wear.

- ● Polyurethane

- Due to its elasticity, this is most recommended for roller bearings and similar applications.

- ● 440C, 304, 316L Stainless Steel

- Affordable and excellent for corrosion resistance.

- ● Cronidur 30

- A high-performance steel that’s great for extreme conditions.

- ● Ceramics

- This includes materials like Aluminum Oxide (Al2O3), Silicon Nitride (Si3N4), Silicon Carbide (SiC), and Zirconia (ZrO2) — all of which provide high temperature and wear resistance for demanding applications.

Custom Size

We design and manufacture bearings in a wide range of sizes which can accommodate all types of applications. From consumer goods to aerospace components to high-precision bearings for machinery, we've got you covered.

Industries That Often Use Custom Bearings

Custom bearings are essential across a variety of industries, each with unique requirements and challenges. Some of those key industries include:

- ● Aerospace

- Because custom bearings are often used for aircraft engines, landing gear, and navigation systems, they require reliability under extreme conditions, including high speeds and varying temperatures.

- ● Automotive

- The automotive industry relies on custom bearings for components that demand both durability and precision, such as transmissions, wheel hubs, and electric motors, enhancing vehicle performance and safety.

- ● Industrial Machines

- Custom bearings are integral for heavy-duty and specialized equipment. They support high loads, reduce downtime, and improve the overall efficiency of machinery in manufacturing, mining, and construction.

- ● Medical Equipment

- Precision and reliability are paramount in medical equipment. Custom bearings are used in devices like MRI machines, surgical tools, and diagnostic equipment, ensuring accurate and smooth operation, which is critical for patient safety and effective treatment.

- ● Emerging Fields

- Innovations in robotics and automation drive the need for custom bearings that can meet specific demands. These bearings enable advanced functionalities in robotics, drones, and automated systems, contributing to the growth of these cutting-edge fields.

- ● Miniature Bearings with Flanges

- Perfect for high-precision, small-scale applications.

- ● Thrust Bearings

- Ideal for handling axial loads in high-pressure applications.

The Right Custom Bearing: A Quick Selection Guide

Designing the right bearing involves considering several factors:

- ● Load Requirements

- Determine radial and axial load needs.

- ● Speed Requirements

- Assess the operating speeds and precision needs.

- ● Environmental Conditions

- Consider temperature, corrosion resistance, and lubrication requirements.

- ● Material Properties

- Select the appropriate material for the application, ensuring it meets the specific demands.

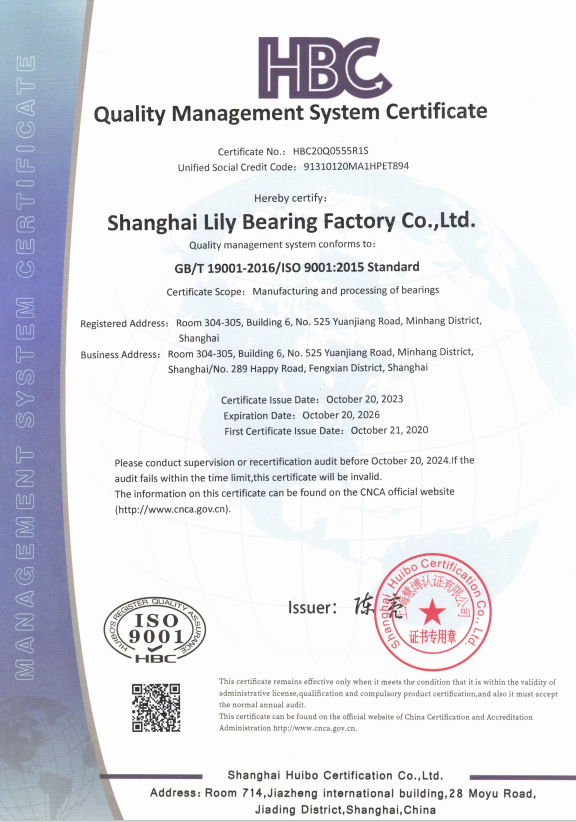

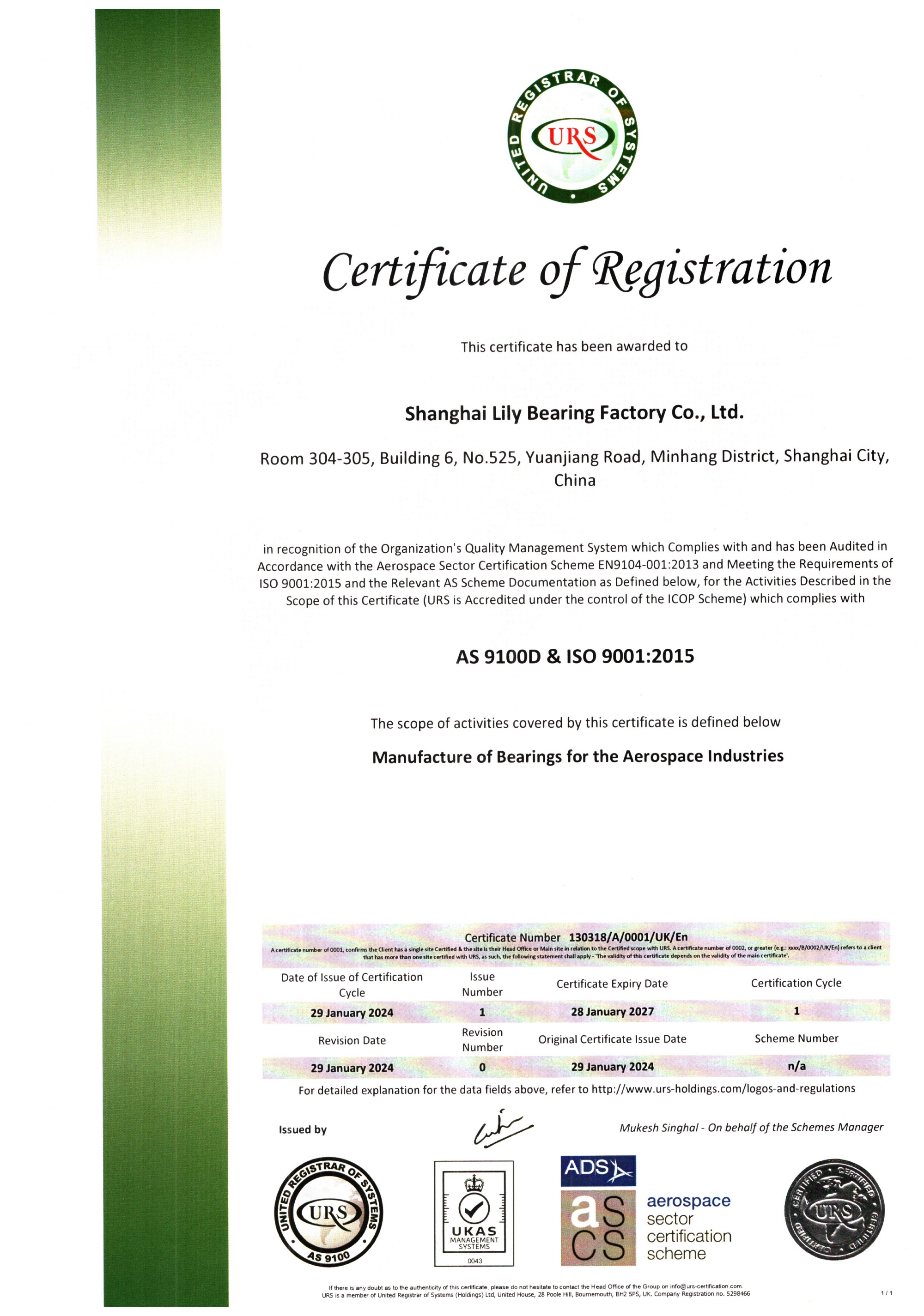

Quality and Certifications of LILY Bearing

We’re serious about providing the best quality and service, while continuing to uphold international standards of quality assurance in custom bearing production. We comply with both ISO 9001 and AS9100 certification standards, among others, as they highlight our commitment to high-quality production and reliable bearing solutions that fit the exact parameters of your needs.

Examples of Custom Bearings We’ve Designed & Manufactured

We specialize in designing and manufacturing all types of custom bearings that fit a wide range of applications. Here are a few examples of the bearings we’re equipped to manufacture:

Miniature Bearing With Flanges

If you need a high level of precision for small-scale applications, miniature bearings with flanges are an excellent choice. They’re used in various high-precision industries, including medical devices and aerospace. These bearings don’t just offer higher performance, but they’re also reliable and ideal for compact spaces.

Silicon Nitride (Si3N4) Ceramic Bearings

Heat resistance and durability make these bearings ideal for applications that require superior wear resistance and low friction — that includes high-speed spindles and vacuum environments. This, combined with their excellent corrosion resistance, makes them ideal for challenging environments.

Constant Section Thin Bearings

Constant section thin bearings are meticulously designed for applications where space is limited, but high precision and load capacity are necessary. You can find these bearings in the robotics, automation, aerospace, and other industries requiring high-load capacity and precision. Their thin section and high-performance design ensure smooth operation and reliability.

Polyurethane Roller Bearings

Polyurethane roller bearings are usually reserved for applications that demand high levels of elasticity and durability, such as conveyor systems and material handling equipment. These bearings provide excellent load-bearing capacity and wear resistance, ensuring long service life and reliable performance in various industrial environments.

Why to Choose LILY Bearing for Custom Bearings?

At LILY Bearing, we succeed in the custom bearing market because of our commitment to flawless engineering, state-of-the-art manufacturing capabilities, and our customer-centric approach. With a vast selection and tailored approaches, we’re dedicated to providing high-performance and reliable bearing solutions for a diverse set of applications. Contact us today to learn more about our custom bearing manufacturing capabilities.