- Equivalent to Manufacturer :

- McGill

Cam Follower

1295 ProductsWhat Is A Cam Follower?

A Cam Follower is a specialized bearing that follows a cam lobe profile to transmit motion and load between machine parts. It is known for its durability and reliability in high-stress environments where traditional bearings may fail. Unlike ball and roller bearings, where the size is determined by the bore diameter (d), cam followers are sized based on their outside diameter (D).

Famous Brands

Some well-known cam follower manufacturers and brands include:

Types of Cam Followers

Cam Followers come in various types and configurations to meet different application needs. They can be classified based on their structure and roller shape.

Based on the structure, Cam Followers can be classified into:

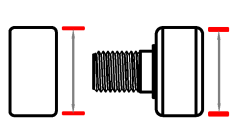

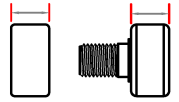

Stud-Type Cam Follower

Stud-type cam followers have a stud that supports the outer ring, making them easy to install and remove. They come in different variations, including:

- Heavy Stud: Offers increased load capacity and durability.

- Cam Followers Stud: Equipped with hex sockets for easy installation.

- Blind Hole: Designed for applications where space is limited, and a through-hole is not possible.

Yoke-Type Cam Follower

Yoke-type cam followers feature a yoke that provides additional strength and stability. These are ideal for applications requiring robust support.

Based on the roller shape, Cam Followers can be classified into:

Crowned Cam Follower

Crowned cam followers have a curved outer surface that provides better load distribution and extends bearing life. They are suitable for applications where even load distribution is critical.

Cylindrical Cam Follower

Cylindrical cam followers have a flat outer surface, making them perfect for high-load applications where stability is key.

Flanged Cam Follower

Flanged cam followers have a built-in flange for axial guidance, which helps maintain bearing orientation and improves performance.

V-Groove Cam Follower

V-groove cam followers contain a V-shaped groove for stable and aligned tracking in roller applications, ensuring precise motion control.

Construction of a Cam Follower

- Stainless Steel Construction: Many cam followers are constructed from stainless steel, which offers excellent corrosion resistance and durability, making them suitable for harsh environments.

- Full Complement of Rollers: A full complement cam follower has a larger number of rolling elements, allowing for a higher load capacity.

- Outer Ring: The outer ring of a cam follower is often designed to be thick-walled to withstand heavy loads.

- Stud Type and Yoke Type: Cam followers come in two main designs: stud type, which has a threaded stud for mounting; and yoke type, which is typically mounted onto a pin or shaft.

Key Features and Benefits of a Cam Follower

Cam Followers offer several key benefits that make them suitable for a wide range of applications:

- High Precision: Ensures accurate and consistent motion transfer.

- Low Friction: Minimizes energy loss and wear, extending service life.

- High Load Capacity: Capable of handling heavy loads efficiently.

- Versatility: Suitable for various applications and environments.

- Easy Installation: Designed for straightforward mounting and maintenance.

- Long Service Life: Built to last, reducing the need for frequent replacements.

Industries that Use Cam Followers

Cam Followers are used in various industries due to their reliability and performance. They are crucial in:

- Metals: Used in metal processing and handling equipment.

- Mining, Mineral Processing, and Cement: Handles the tough conditions in mineral extraction and cement production.

- Railways: Ensures reliable performance in railway systems.

- Material Handling: Used in equipment that requires efficient movement and load handling.

- Agriculture: Great for farming machines, durable and reliable.

- Construction: Used in construction equipment for their robustness and load capacity.

- Machine Tools: Needed for precise and durable machining.

- Industrial Robots: Ensures reliable movement and positioning.

- Electronic Parts Production: Provides precision and reliability.

- Office Equipment: Improves performance and reliability.

- Harsh Environments: Ideal for outdoor use and corrosion resistance with stainless steel cam followers.

Considerations When Selecting a Cam Follower

When selecting a cam follower for a specific application, consider several factors to ensure it performs well and lasts long.

Load Capacity and Radial Loads

Cam followers are designed to withstand radial loads, and their load capacity is a critical factor to consider. Full complement cam followers typically have a higher load capacity due to the increased number of rolling elements.

Temperature Limits and Material Coatings

Operating temperature limits are essential when selecting a cam follower. Stainless steel cam followers can operate at higher temperatures, but additional coatings, such as black oxide, can further enhance their temperature and corrosion resistance.

Thrust Loads and Roller Design

While primarily designed for radial loads, some cam followers can also withstand thrust loads. The roller design, whether crowned or cylindrical, will affect how the cam follower performs under these conditions.

Track Rollers and Outer Ring

Track rollers are similar to cam followers but are designed to run on tracks or rails. The outer ring's design in these bearings is crucial for distributing loads and ensuring smooth movement along the track.

Hex Sockets and Blind Hole Mounting

For stud type cam followers, hex sockets provide a means of securing the bearing in place. When space is limited or the mounting surface cannot be tapped, a blind hole can be used with a hex socket to mount the stud.

High Load and Durability

Cam followers designed for high load applications are built to be robust and durable. They are made with high-quality materials and engineered to withstand the demands of heavy-duty operations.

Why Choose LILY Bearing?

LILY Bearing offers a wide variety of cam followers for different industries. Our cam followers and track rollers reduce friction, converting rotation to linear motion or supporting radial and thrust loads, based on the type of rolling elements used.

Advantages of LILY Bearing Cam Followers

- High Quality: Made to top standards for precision and reliability.

- Customization: Solutions tailored to your specific needs.

- Corrosion Resistance: Stainless steel options for outdoor and tough environments.

- Expert Support: Professional advice to help you choose the right cam followers.

Explore our wide range of cam followers to find the perfect match for your machinery, ensuring top performance and long-lasting durability.