Cancel

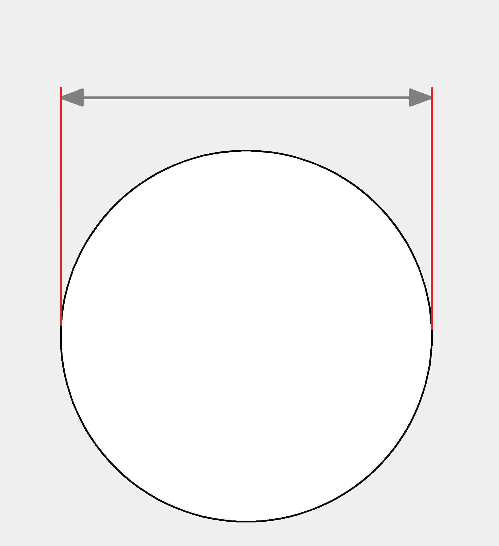

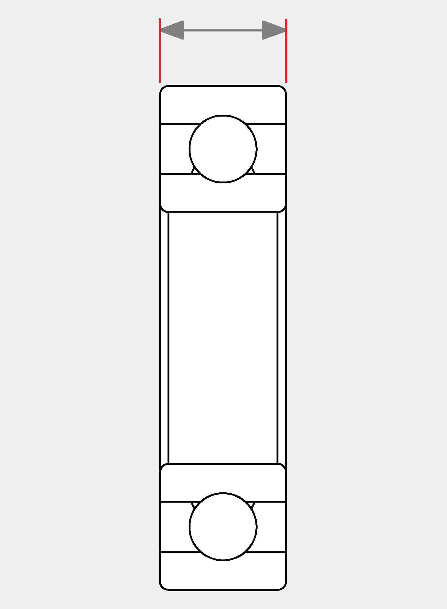

Bore Dia

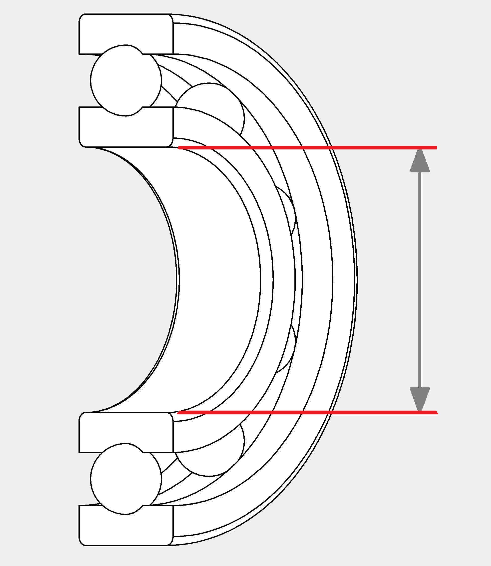

Ball Diameter

Ring Material

Washer Material

For Load Direction

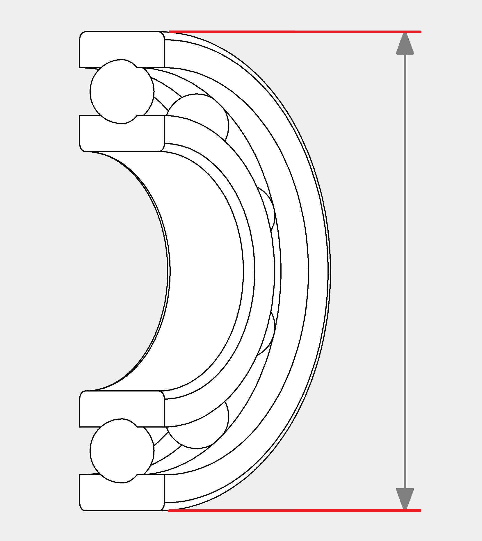

Outer Dia

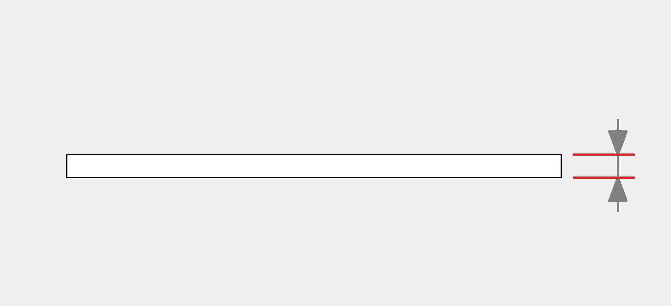

Width

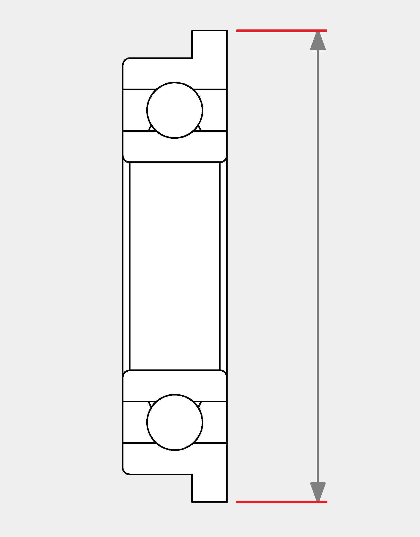

Height

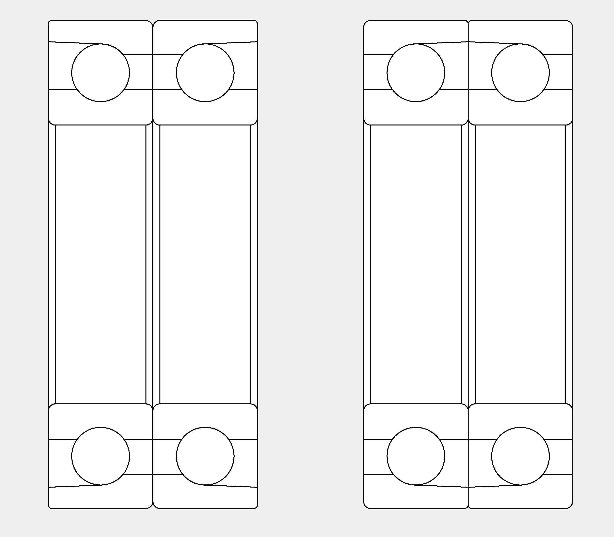

Matched Arrangement

Preload

Flange Outer Dia

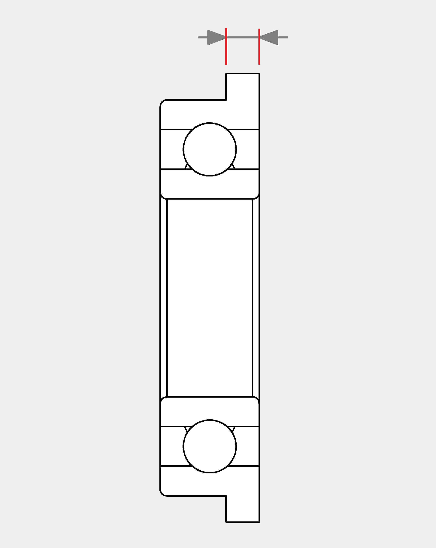

Flange Thickness

Balls Material

Temperature Range

Dynamic

Dynamic Axial Load

Static

Static Axial Load

Product Categories

/ Ceramic Bearings

Ceramic Bearings

10713 ProductsFull Ceramic Bearings

Hybrid Ceramic Bearings

Ceramic Balls And Ceramic Components

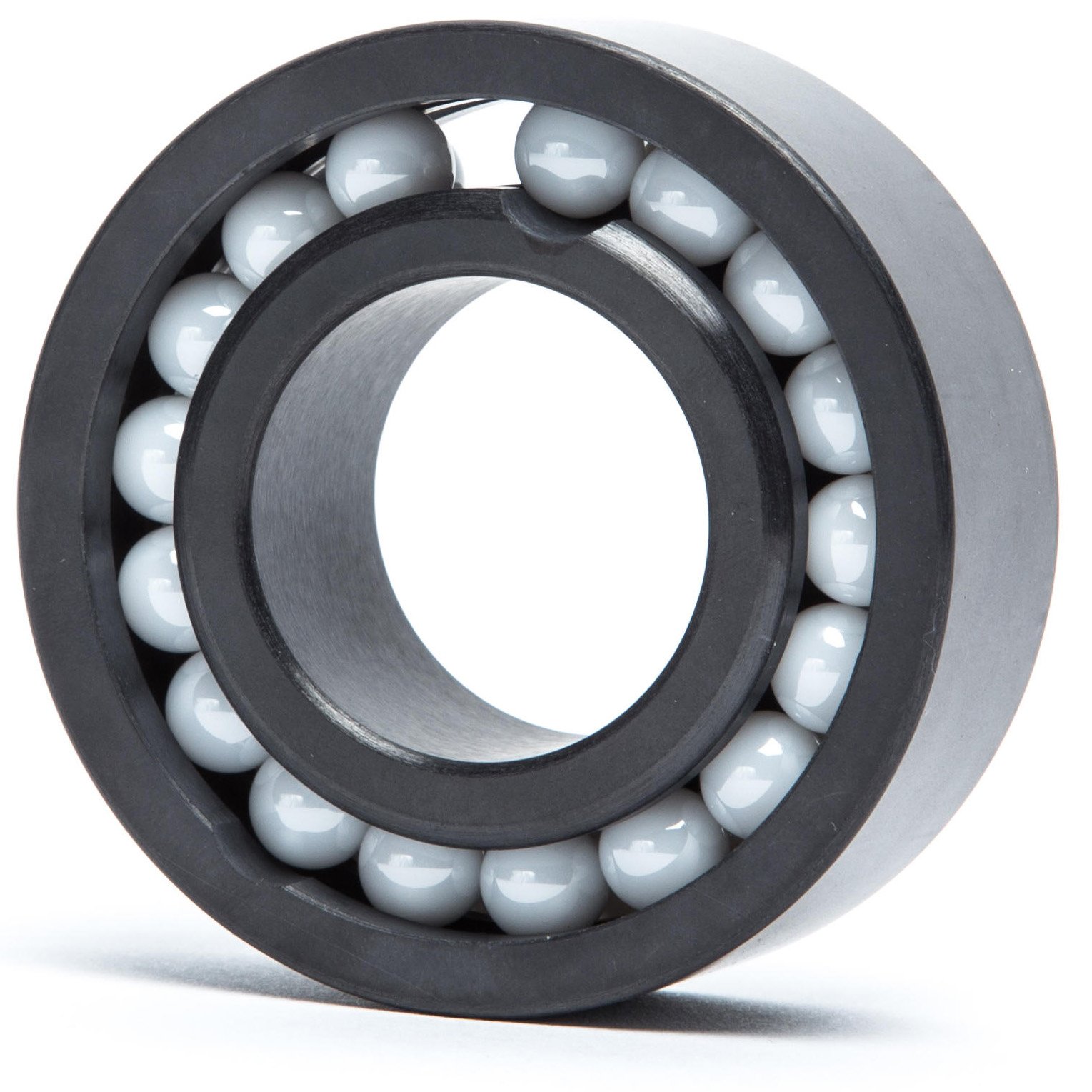

There are two kinds of ceramic bearing: hybrid ceramic bearing and full ceramic bearing. The rolling elements ofare made in ceramic material, the races are made in chrome steel, for full ceramic bearing, both rolling elements and races are made in ceramic material. here is the introduction of ceramic materials and their properties.

Looking for Ceramic Bearings that offer superior protection against contamination and moisture? Check out our Sealed Ceramic Bearings, designed with an additional seal to prevent dust, dirt, and water from entering the bearing. Ideal for applications that require long-lasting and maintenance-free performance in harsh environments.

We offer ceramic bearings in three different materials, namely zirconia, silicon nitride, and silicon carbide. These bearings offer superior performance compared to traditional metal bearings. Zirconia ceramic bearings are known for their high strength, toughness, and resistance to wear and corrosion, making them ideal for use in harsh operating conditions.

Silicon nitride ceramic bearings are extremely hard, durable, and lightweight, with excellent heat resistance and electrical insulation properties, making them ideal for use in high-temperature and high-speed applications. Silicon carbide ceramic bearings are known for their excellent hardness, stiffness, and chemical resistance, making them suitable for use in extreme operating conditions such as high temperatures, high loads, and corrosive environments.

What are Ceramic Bearings?

Ceramic Bearings are sometimes a cylindrical type of bearing. These are made to reduce friction and improve durability. Ceramic Bearings are typically some sort of hybrid bearing with ceramic balls inside steel bearing races.

What are Ceramic Bearings Used For?

Ceramic bearings are heavily used in bike components. Most commonly included in hubs, bottom brackets, pulley wheels and headsets. These are typically used in parts where reduced friction and increased durability are desired.

Benefits of Ceramic Bearings

Ceramic Bearings have excellent performance with their special electrical and magnetism resistance, wear and corrosion resistance, maintenance free lubrication, and high and low temperature resistance.

Why LILY Bearing?

Find Solutions for today’s challenging applications with LILY Bearing. With over 60,000 bearing types ranging from 1.5 mm I.D. to 4000 mm O.D, you are sure to find the perfect fit for all components. Shop the leading supplier of bearings with LILY.

Order Prompt

The order is added successfully. You can click order to pay or view