Stainless Steel Ball Bearings

3132 ProductsStainless Steel Ball

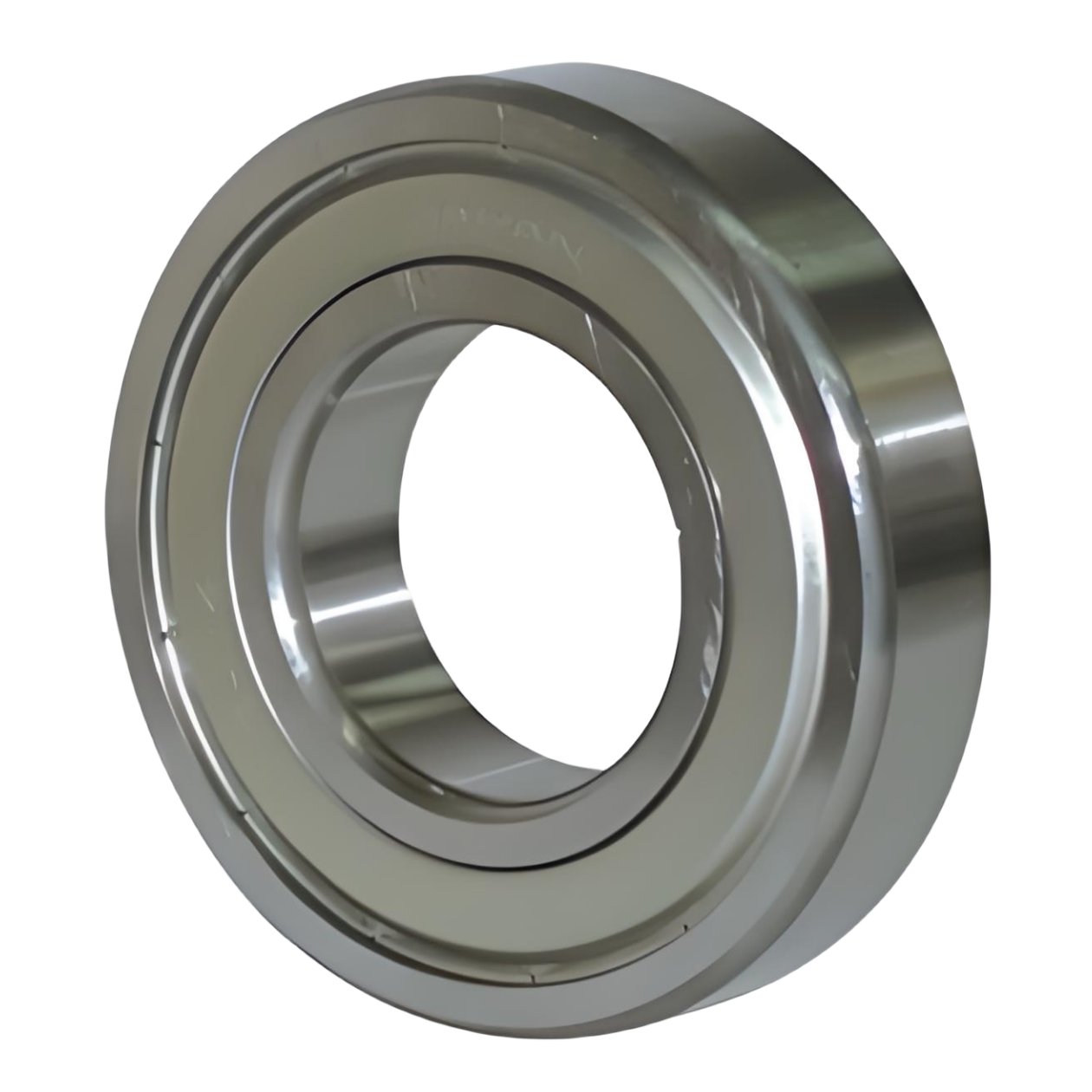

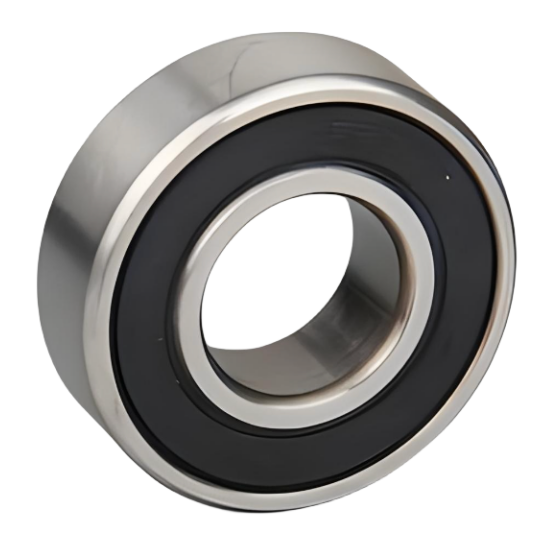

What are Stainless Steel Ball Bearings?

They’re made of stainless steel balls that are housed between the inner and outer rings. In many cases, they are also separated by a retainer or cage. These precision-engineered components provide both smooth rotation and support for radial and thrust loads. Plus, they are more rust and corrosion resistant compared to other types of ball bearing materials.

Types of Stainless Steel Ball Bearings

At LILY Bearing, we offer stainless steel ball bearings that are available in various grades, each offering unique properties and use cases. Some of the most common types of stainless steel ball bearings in our collection include:

AISI 440C

Known for its hardness and wear resistance, this high-carbon martensitic is typically used in applications that require corrosion resistance and high load capacities. This can include use in food processing machinery, cleaning equipment, and other equipment used in high temperature and humidity environments.

AISI 304

These bearings are typically best for circumstances where corrosion resistance is imperative, but hardness isn’t. Since they’re very resistant to many corrosive substances (i.e., organic chemicals, oxidizing solutions, dyes, etc.), they’re most often used in the food and chemical processing industries.

AISI 316L

AISI 316L is a low-carbon austenitic stainless steel that offers superior chemical resistance (especially in chloride environments) and corrosion resistance. Further, they can withstand the sterilization process better than most other materials. As such, it’s used most commonly in marine applications and for medical equipment.

Stainless Steel vs. Other Materials

- Compared to other types of bearing materials, stainless steel stands out for many reasons. Here’s how it stack ups against other types of materials:

- Chrome Steel: This material is hard and very durable. However, it lacks the corrosion resistance of stainless steel.

- Ceramic: While this material offers great corrosion existence and performs well in hot temperatures, it’s expensive and not as durable as stainless steel.

- Carbon Steel: Though carbon steel costs less than stainless steel, it’s also more likely to rust or corrode in humid or wet environments.

Common Uses of Stainless Steel Ball Bearings

Due to their affordability, corrosion resistance, and durable nature, stainless steel ball bearings are used across various industries:

Food Processing

Stainless steel bearings are used in food processing equipment because they help to prevent contamination and can withstand frequent cleaning and sanitization.

Medical Equipment

Since stainless steel ball bearings are resistant to corrosion and can be cleaned relatively easily, they are a great match for medical devices that need to operate reliably and in sterile environments.

Marine Applications

They are ideal for marine equipment, vehicles, and offshore equipment because they’re resistant to salt water corrosion.

Chemical Processing

Unlike other types of materials, stainless steel can withstand the corrosive substances it’s exposed to in chemical processing equipment.

Benefits of Stainless Steel Ball Bearings

Stainless steel ball bearings offer several advantages over other ball bearing materials:

- Excellent corrosion resistance in corrosive environments

- High durability and long service life

- Ability to withstand high temperatures

- Can be used in clean room environments

- A high degree of resistance to many chemicals and cleaning agents

- Can handle heavy loads

- Available in all types of configurations (open, rubber sealed, PTFE sealed)

Choosing the Right Stainless Steel Bearings

Selecting the best kind of stainless steel ball bearing for your project involves the consideration of many factors:

- Environmental conditions (humidity, temperature, exposure to chemicals)

- Load requirements (radial and axial loads)

- Speed requirements (suitable for high-speed applications)

- Size constraints (including miniature ball bearing options)

- Sealing requirements (open, rubber sealed, or shielded designs)

- Precision and tolerance needs

- Special features (e.g., self-aligning capabilities, flanged designs)

- Bearing configuration (single row, double row, angular contact)

Consider consulting LILY Bearing's extensive catalogs and technical resources to ensure you select the optimal bearing for your application.

Have questions? Contact our customer service team today.

Maintenance and Care Tips

On its own, stainless steel is very durable. However, you can extend the service life of your bearings even further by conducting regular maintenance and upkeep:

- Use appropriate lubricants compatible with stainless steel

- Implement regular cleaning and inspection schedules

- Avoid exposure to unnecessary contaminants

- Constantly monitor operating conditions (load, speed, temperature)

- Ensure proper alignment during installation

- Replace bearings as soon as signs of wear appear and at recommended intervals

Why Choose LILY Bearing for Stainless Steel Ball Bearings

LILY Bearing offers a comprehensive range of high-quality stainless steel ball bearings to meet diverse industrial needs. Our selection of more than 100,000 bearing options ensures we’ll have the ball bearings you need when you need them. That includes:

- Deep groove ball bearings

- Angular contact ball bearings

- Thrust ball bearings

- Self-aligning ball bearings

- Flanged ball bearings

- Miniature ball bearings

- Pillow block bearings with stainless steel inserts

With more than 20 years of industry experience, in-depth product knowledge, and impeccable quality assurance, we’re here to help you make your next project a success. Explore our bearing collection today.