Cancel

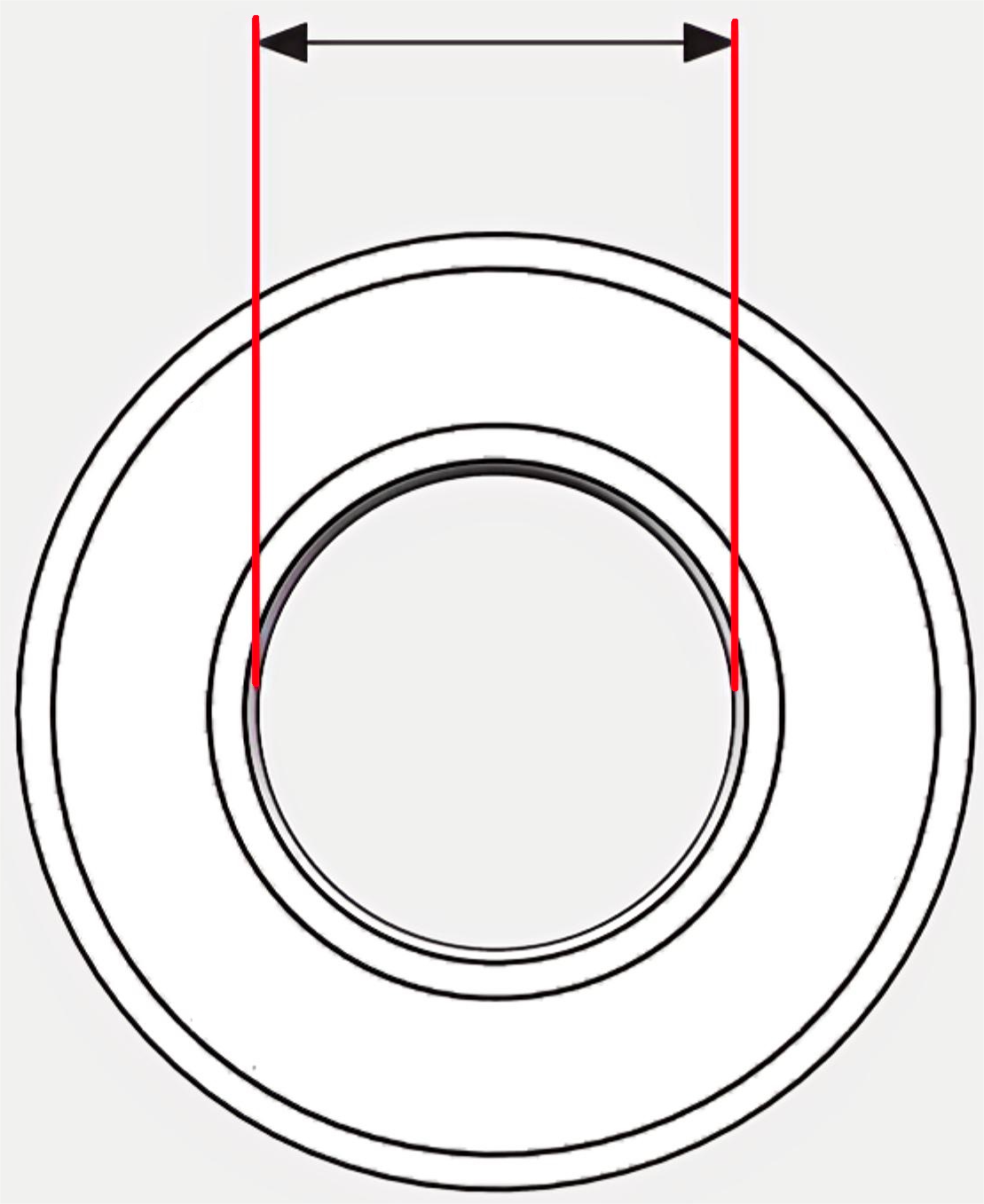

Bore Dia

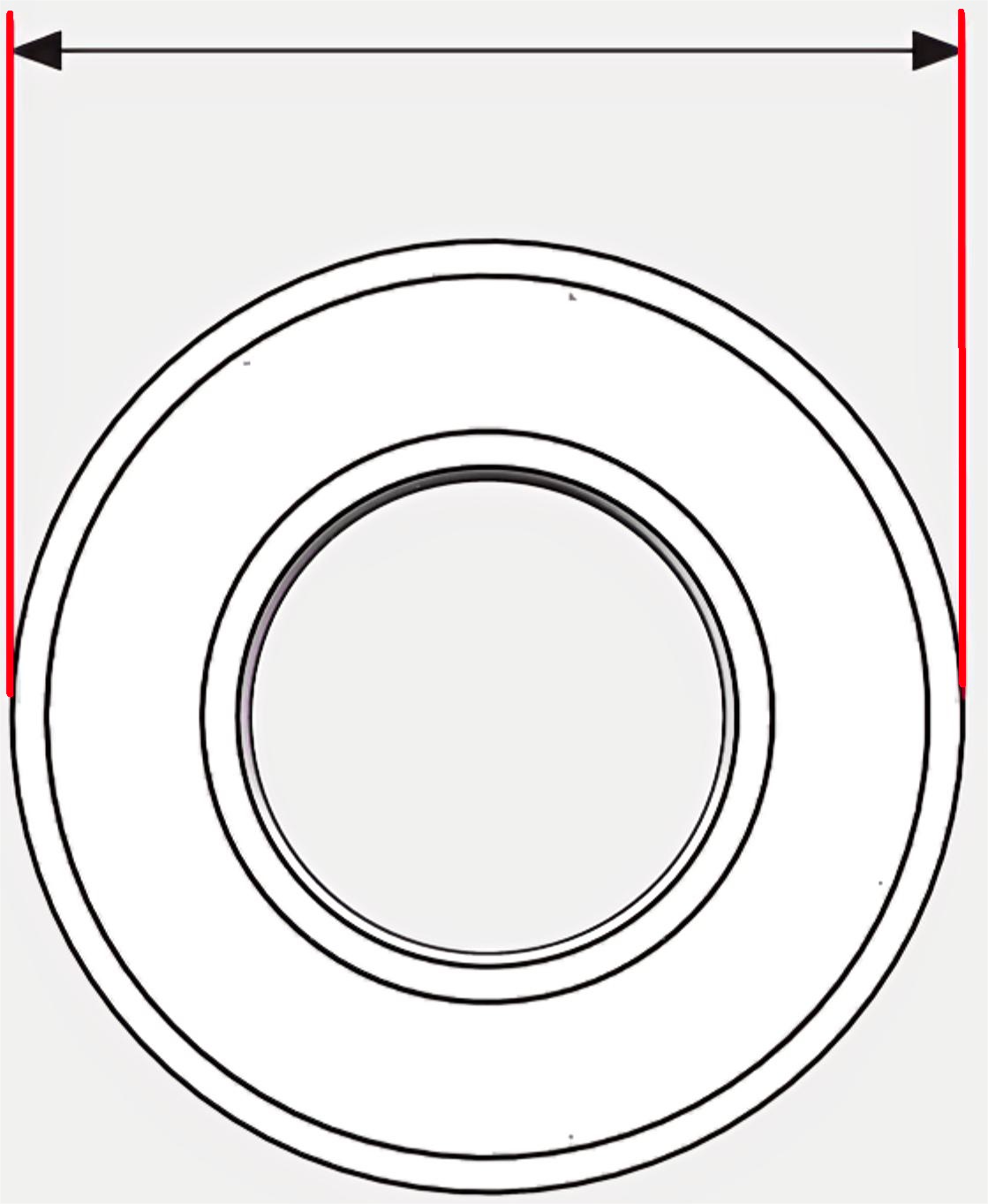

Outer Dia

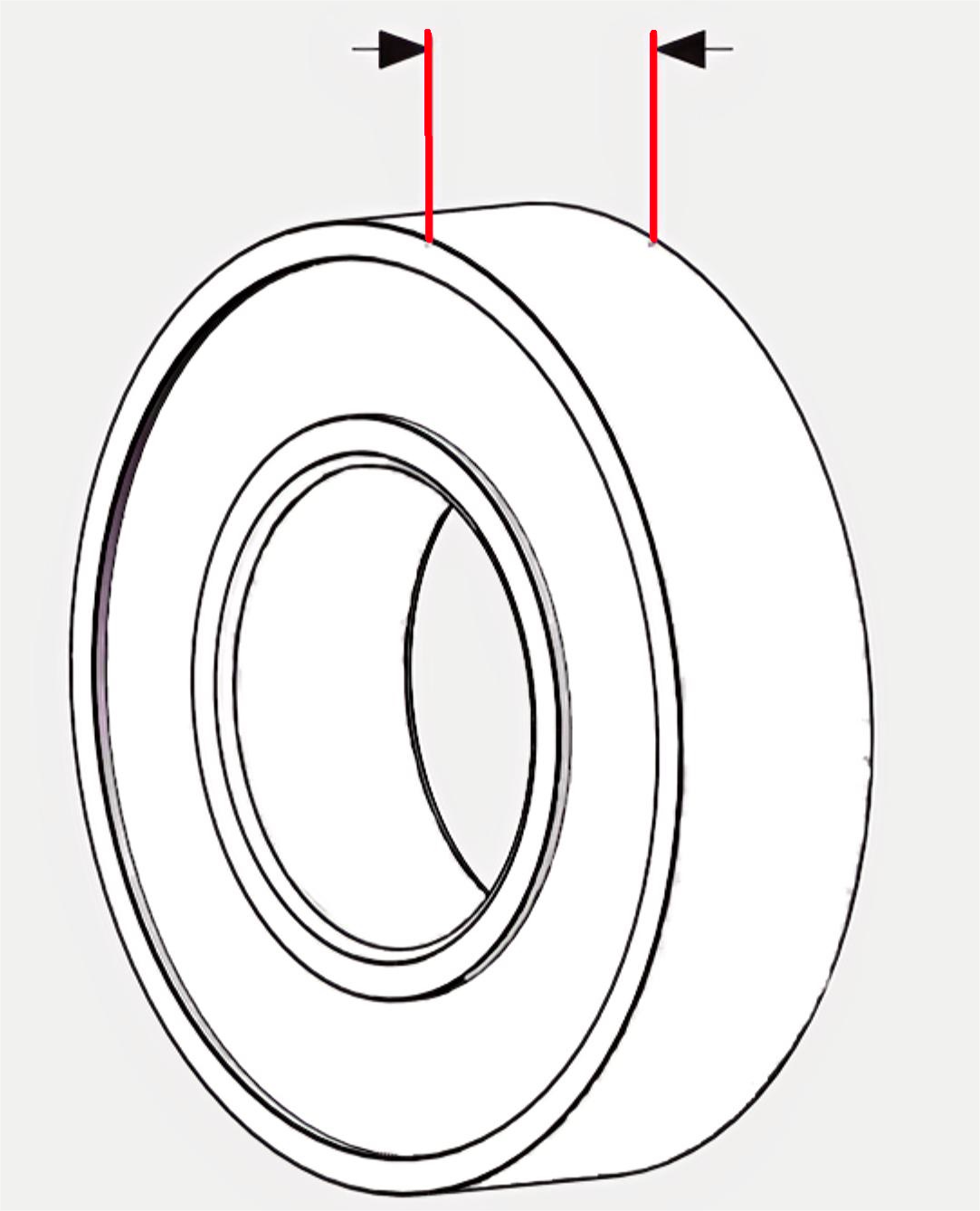

Width

Cage Material

Seal Type

For Load Direction

- Equivalent to Manufacturer :

- SKF

Super Precision Cylindrical Roller Bearings

419 ProductsWhat are Super Precision Cylindrical Roller Bearings?

Super Precision Cylindrical Roller Bearings are high-performance bearings designed for accuracy and low friction at high speeds, ideal for advanced machinery and precision tools. They're made with cutting-edge materials to deliver superior performance.

Features of Super Precision Cylindrical Roller Bearings

- High-Speed Capability: These bearings are built to handle high speeds smoothly, minimizing both vibration and heat.

- High Rigidity: Their construction ensures they're stiff and stable, perfect for tasks needing exact precision.

- Durability: Advanced materials and heat treatment processes result in a bearing that can withstand harsh conditions and extended use.

- Thermal Stability: They stay accurate in shape and size, no matter the temperature changes, for reliable performance.

Common Types of Super Precision Cylindrical Roller Bearings

- Single Row Bearings: Equipped with a heat-resistant PEEK cage and durable SHX steel, these bearings are engineered for a high dmN value of 2.2 million, indicating superior performance at high speeds.

- Double Row Bearings: They boost tool performance, offering high speed with less heat and durable life. They stay stable at fast speeds, thanks to a rigid PPS resin cage.

Applications of Super Precision Cylindrical Roller Bearings

Super Precision Cylindrical Roller Bearings are vital in many areas where accuracy and performance matter most. They're key in:

- Machine Tools: For precision cutting and machining.

- Medical Devices: Essential in equipment like MRI machines for exact results.

- Aerospace: Used in jet engines and parts where failure is not an option.

- Automotive: For the high demands of performance vehicle parts, where durability meets precision.

Selection and Maintenance

Choosing and caring for Super Precision Cylindrical Roller Bearings involves a few key steps for optimal use:

- Understand Loads: Know the radial and axial forces your bearing needs to handle.

- Speed: Ensure the bearing's design suits your application's speed demands.

- Lubrication: Use the right lubricant for the bearing's operating conditions to reduce wear.

- Regular Checks: Stick to a maintenance schedule to keep your bearings in top shape and working precisely.

By considering these factors, you can ensure your bearings perform well and last longer.