Cancel

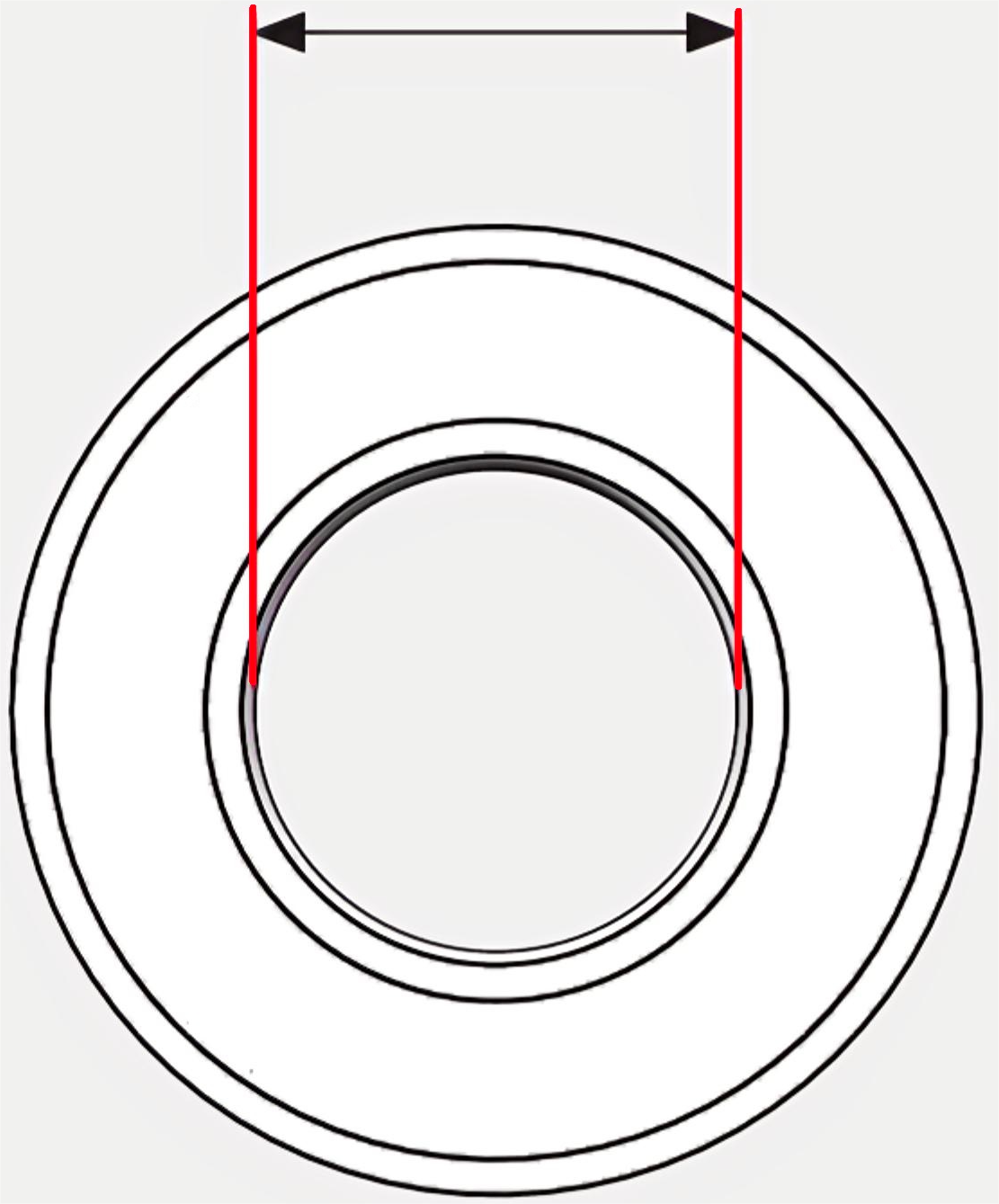

Bore Dia

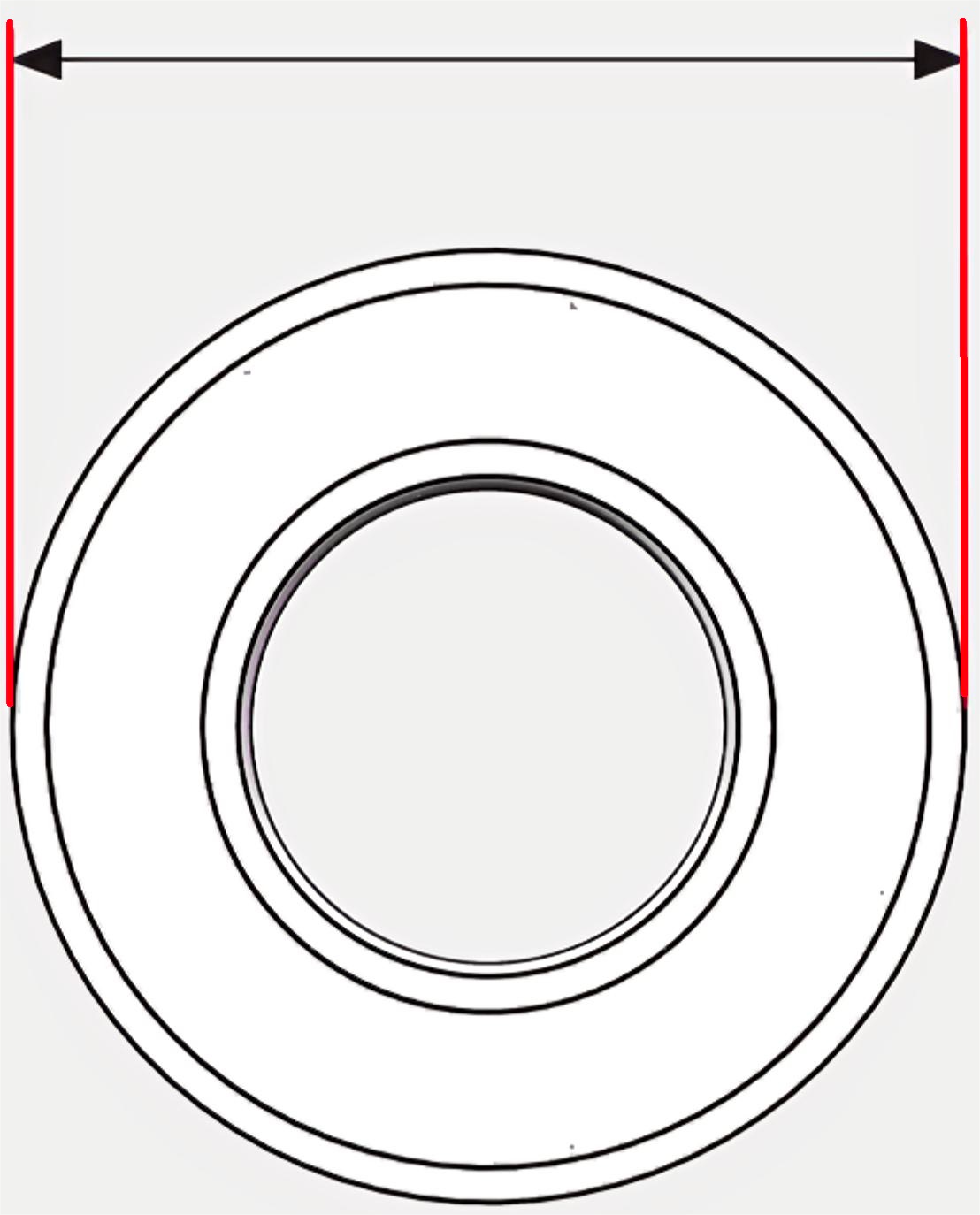

Outer Dia

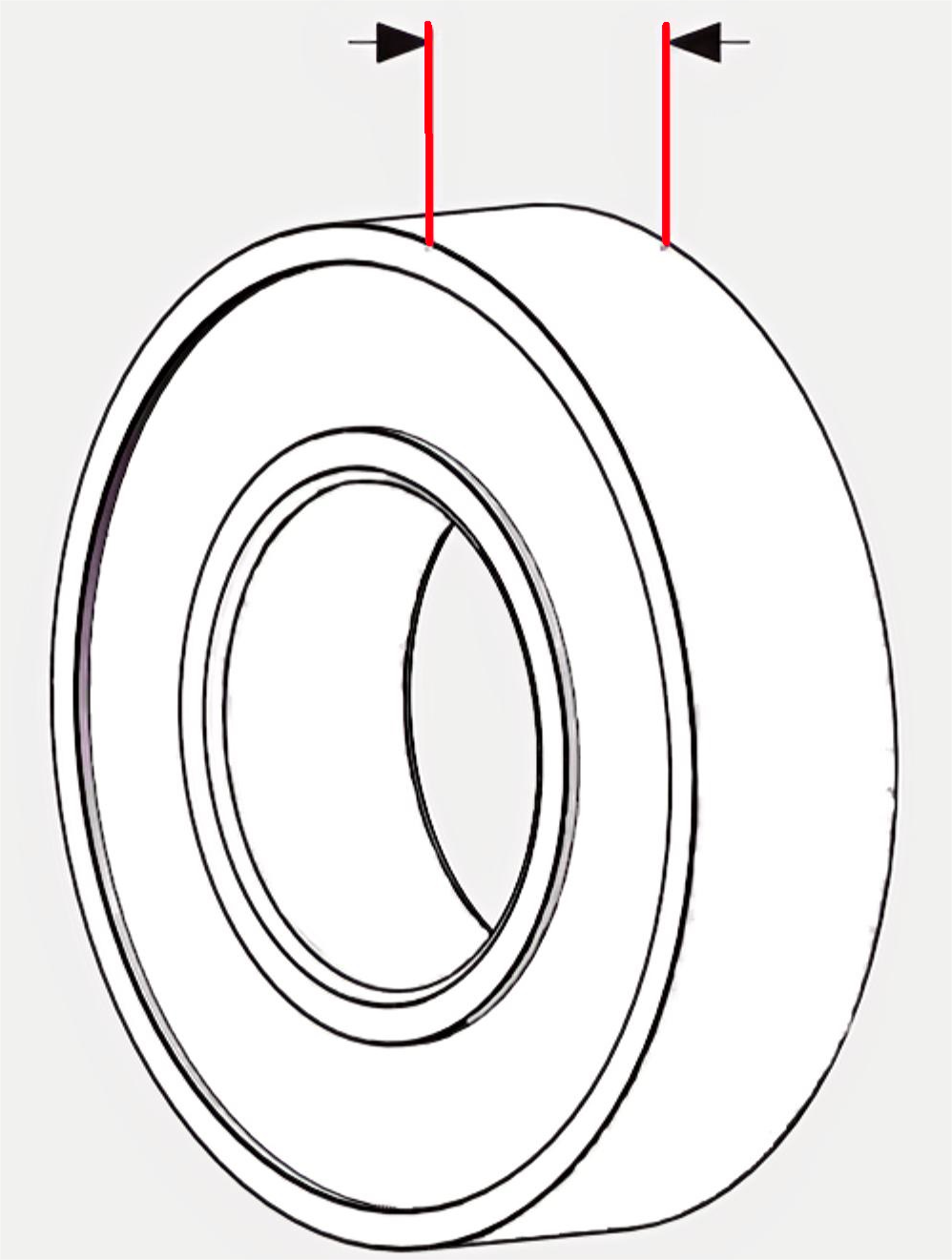

Flange Dia

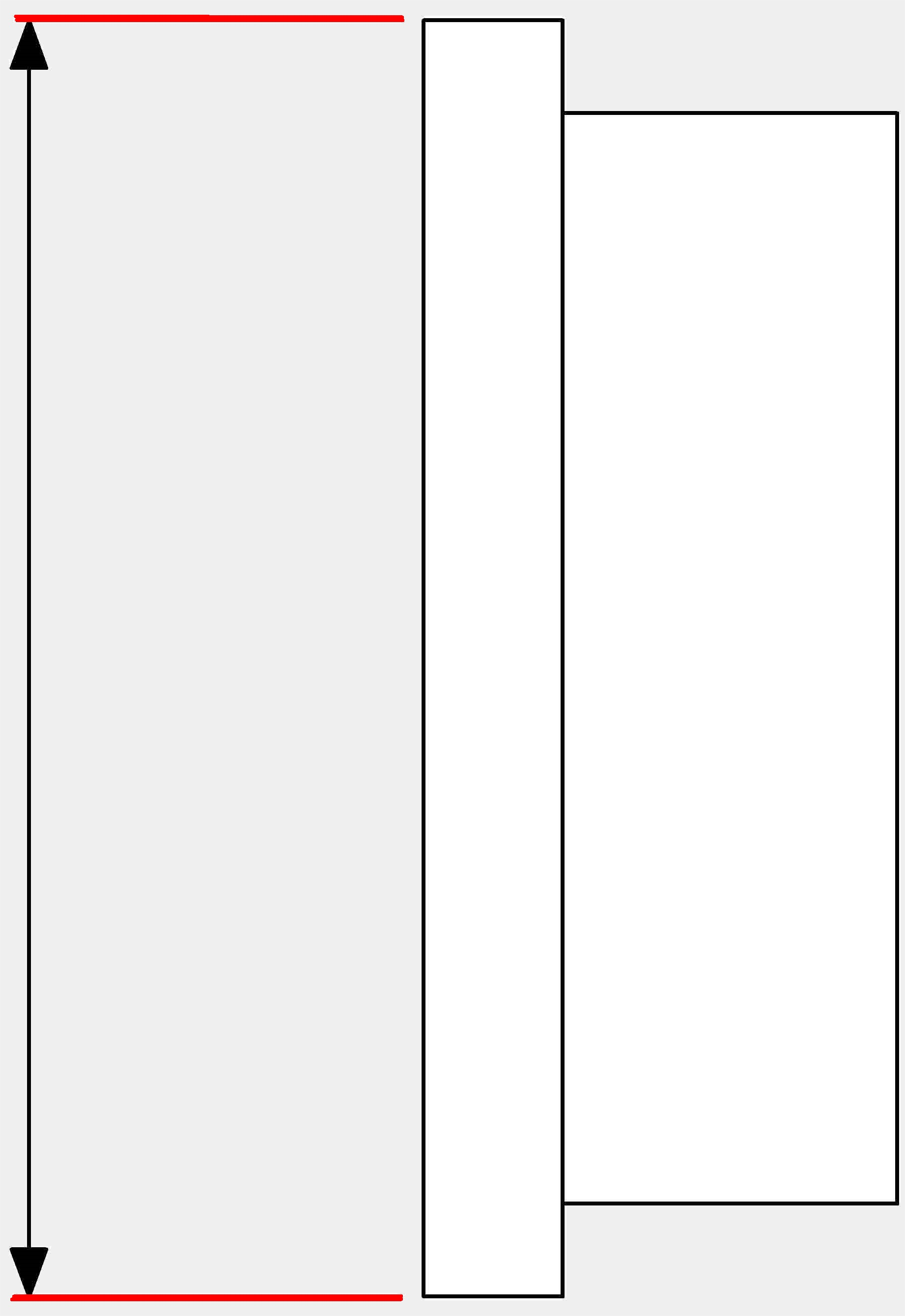

Height

Dynamic Radial Load

Static Radial Load

Dynamic Axial Load

Static Axial Load

Weight

- Equivalent to Manufacturer :

- Schaeffler (INA)

Rotary Table Bearings

60 ProductsRotary Table Bearings are precision-engineered for applications with combined axial, radial, and tilting loads, essential in advanced, high-accuracy machinery. YRT Rotary Table Bearings are a specialized subtype in this category.

Design and Construction of Rotary Table Bearings

- Dual-Direction Axial Bearings: Rotary table bearings are designed to manage axial loads in both directions, along with radial loads and tilting moments.

- Centripetal Guide Bearing: Incorporating a centripetal guide bearing adds stability and boosts overall load capacity.

- Complex Structure: Generally comprising an axial needle or cylindrical roller, cage assembly, outer ring, L-section ring, and shaft locating washer.

Features of Rotary Table Bearings

- High Precision: These bearings typically achieve P4 and P2 precision levels, suitable for highly accurate applications.

- Rigidity and Load Capacity: Their pre-loaded structure ensures high rigidity, with the ability to handle substantial radial and axial loads, and tilting moments.

- Speed Adaptability: Standard YRT bearings cater to lower speeds, while YRTS variants are for high-speed uses, featuring low frictional torque and higher speed limits.

Specialized Variants of Rotary Table Bearings

In addition to the regular series YRT/YRTC and YRTS, some specialized variants of rotary table bearings are also common:

- YRTM/YRTSM: These variants incorporate an angular displacement monitoring system, improving the precision in control and positioning, essential for applications like rotary tables or indexing plates in machine tools.

- ZKLDF: Focused on high-speed applications, these axial angular contact ball bearings are designed for conditions requiring high axial, radial loads, and tilting rigidity, with a contact angle of 60° for enhanced performance.

Applications of Rotary Table Bearings

- Machine Tools: Used extensively in CNC machine tools for components like rotary tables and milling heads.

- Precision Turntables: Ideal for applications requiring high-precision rotation, such as in indexing tables.

- Direct Drive Axes: The YRTS series, in particular, is suited for direct drive axes in machine tools, benefiting from its high limiting speeds.

Installation and Maintenance

- Ease of Installation: With fixing holes in the bearing rings, rotary table bearings are straightforward to install.

- Preloading: They are radially and axially preloaded after fitting, which enhances their rigidity and performance.

- Lubrication: These bearings typically come pre-greased and can be lubricated through specific provisions in the outer ring and L-section ring.

Operating Conditions

- Temperature Range: Suitable for a broad range of operating temperatures, typically from -30°C to +120°C.

- Sealing: Equipped with effective sealing mechanisms to protect against contaminants and maintain lubrication.