Flanged Ball Bearings

676 ProductsWhat are Flanged Ball Bearings?

Flanged ball bearings are durable mechanical elements designed to handle both radial and axial loads through a circular assembly of balls. They prevent misalignment, reduce wear, and ensure smooth rotation even under load. With their inherent resistance to hostile environments and vibrations, they represent a reliable solution for numerous industrial applications.

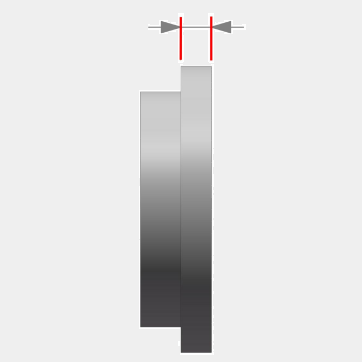

Structure of Flanged Ball Bearings

-

Flanged Design: This extension enhances mounting support, aids in axial location, and prevents the bearing from misalignment within its assembly.

-

Grooved Inner and Outer Raceways: They can enable smooth rolling of the balls. The low friction generated by the rolling balls facilitates the efficient translation of loads.

-

Cage or Retainer: The cage's role in flanged ball bearings is crucial. It maintains the separation between balls, reducing friction and facilitating smoother operation.

-

Sealing or Shielding: They can prevent the ingress of dust, dirt, and other contaminants, ensuring optimum performance and durability.

Types of Flanged Ball Bearings

- Standard Flanged Ball Bearings: Ideal for most applications requiring a flanged bearing. Miniature flanged bearings are speciafically tailored for compact, high-precision applications.

- Flanged Ball Bearings with Extended Inner Ring: providing additional shaft support for higher loads and increased rigidity

Materials Used in Flanged Ball Bearings

Materials used in the construction of flanged ball bearings largely depend on the application. Commonly used materials include:

-

52100 Chrome Steel: the most common material with high strength and durability

-

Stainless Steel: for applications where corrosion resistance is required; such as 440C Stainless Steel

-

Ceramic: used in specific applications where high heat resistance and low corrosion are paramount. Ceramic can also offer a lower coefficient of friction compared to metal.

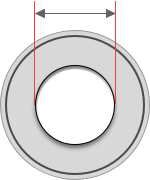

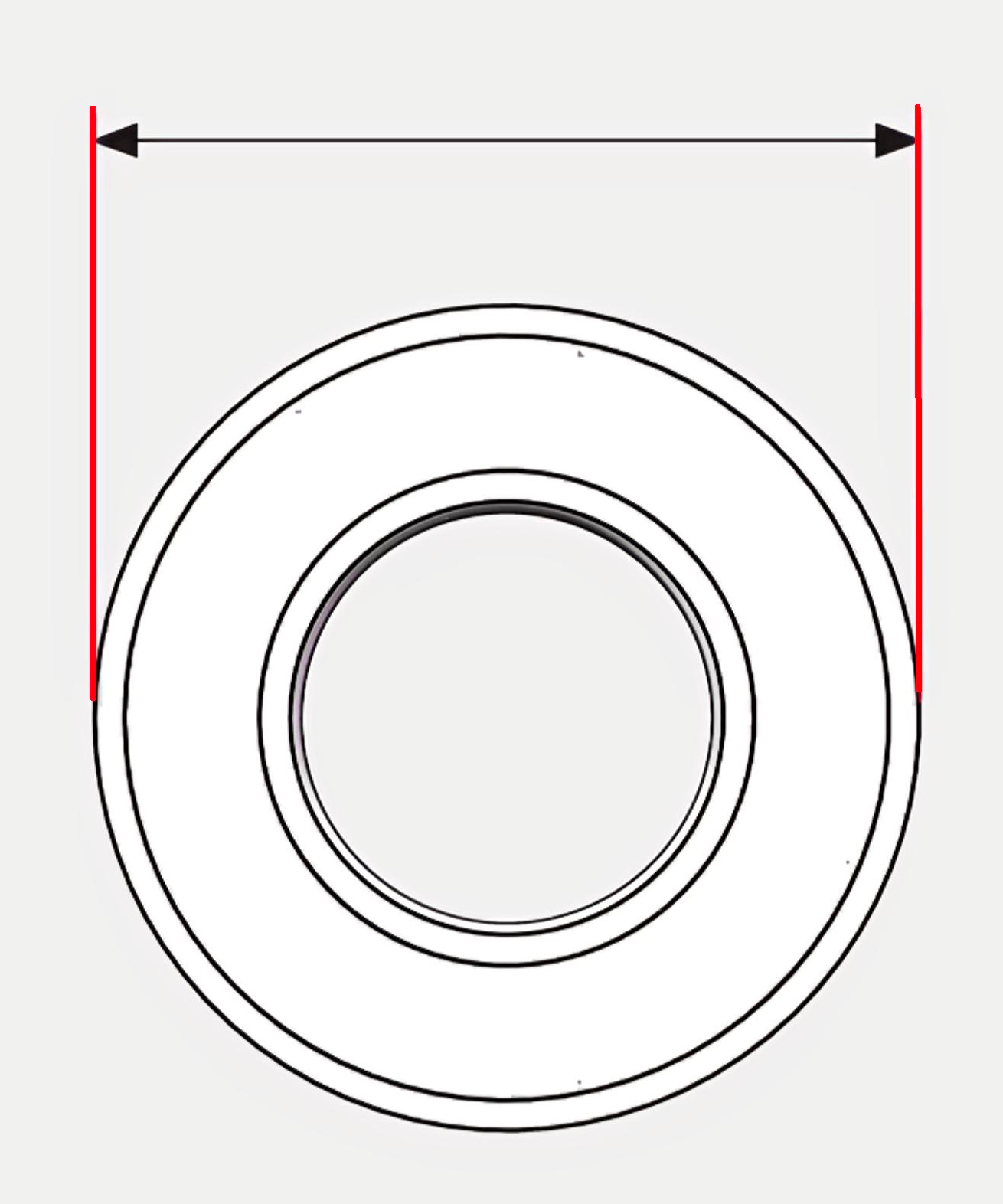

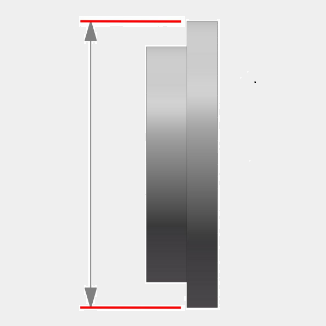

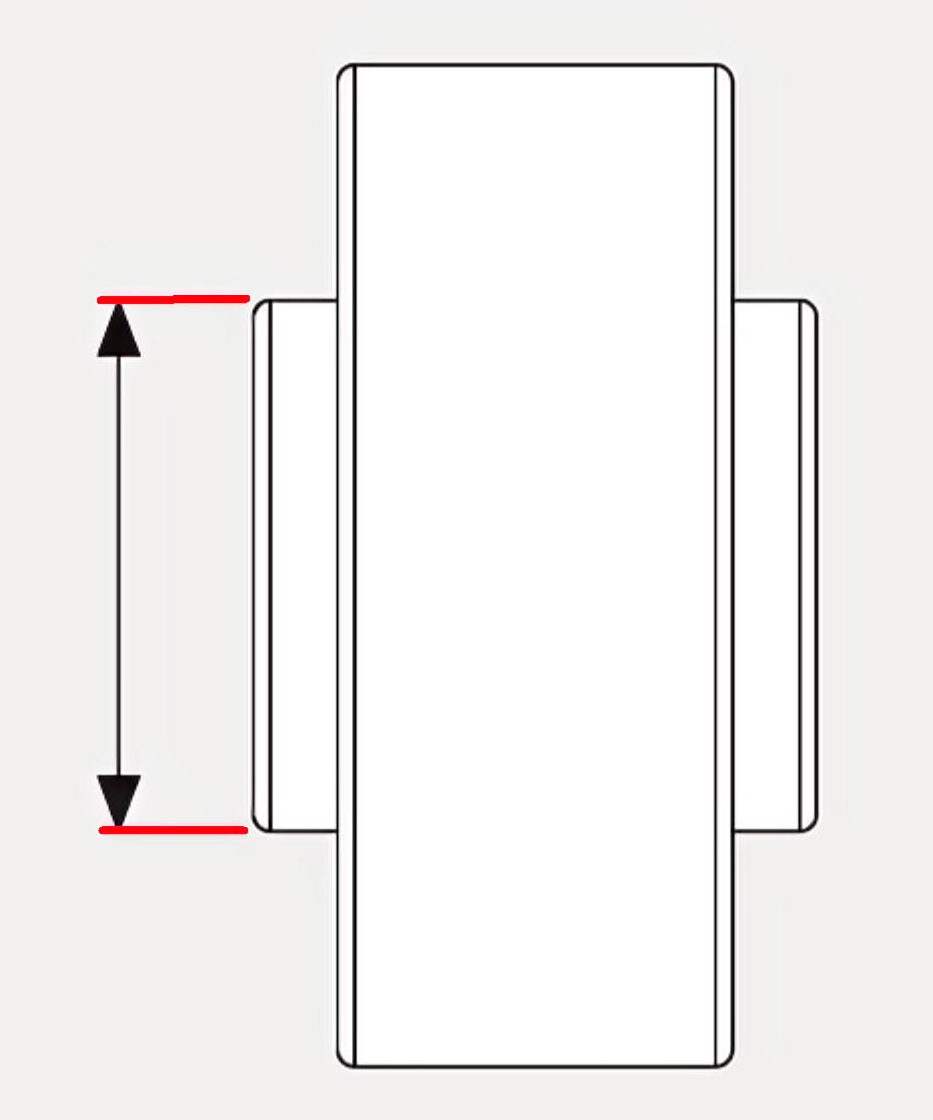

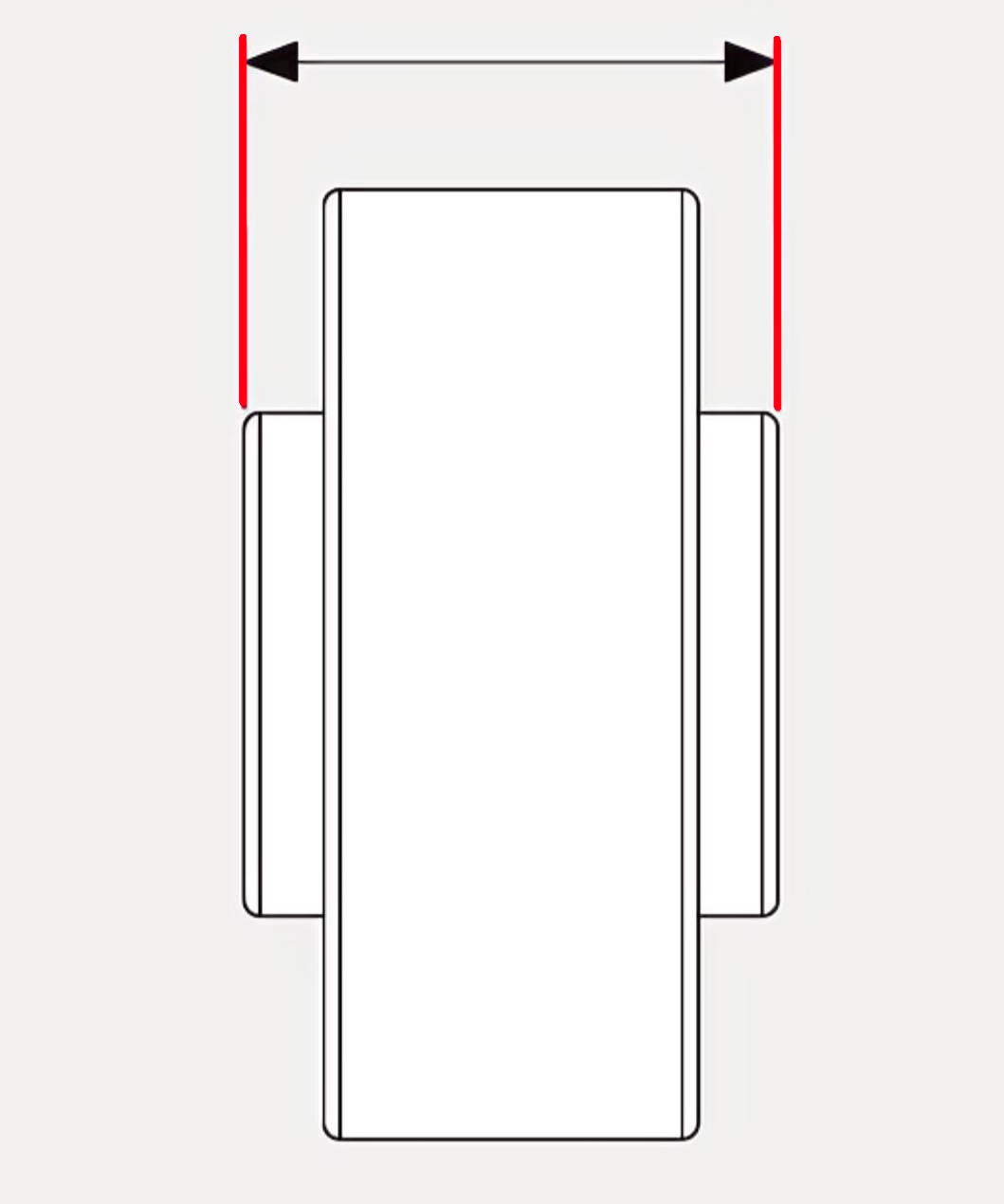

Dimensions of Flanged Ball Bearings

Sizes of flanged ball bearings vary greatly to suit a wide range of applications. The most common sizes are typically between 1/8 inch and 1 inch in diameter. About the maximum and minimum Size, please refer to the table:

|

|

imperial |

metric |

||

|

Minimum Size |

Maximum Size |

Minimum Size |

Maximum Size |

|

|

Bore dia |

0.04688" |

0.375" |

1mm |

50mm |

|

Outer dia |

0.15625" |

0.875" |

3mm |

72mm |

|

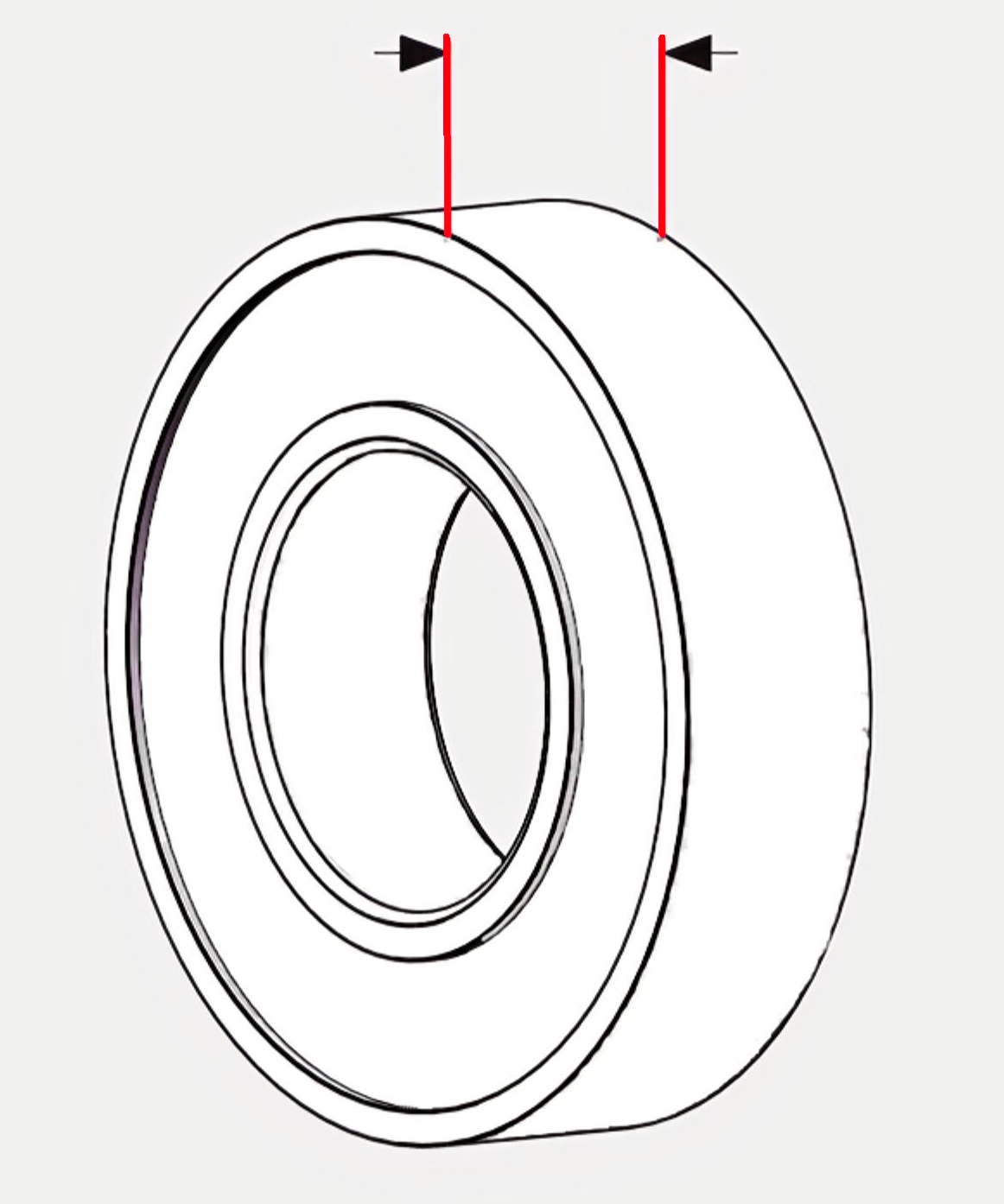

Width |

0.0625" |

0.2812" |

1mm |

12mm |

|

Flange outer dia |

0.203" |

0.965" |

3.8mm |

7.5mm |

|

Flange thickness |

0.013" |

0.045" |

0.3mm |

2.5mm |

What Are Flanged Ball Bearings Used For?

Flanged ball bearings find use across a multitude of industries, including:

-

Elevator systems

-

Conveyor/ conveyor belt systems

-

Power transmission

-

Industrial machinery

-

Agricultural machinery

-

Packaging systems

Utilize our Flanged Ball Bearings Cross Reference Charts to accurately select the ideal bearings for your specific applications.