- Equivalent to Manufacturer :

- Schaeffler (INA)

Needle Bearings

1926 ProductsFamous Brand

Some well-known Slewing bearings manufacturers and brands include:

What are Needle Bearings?

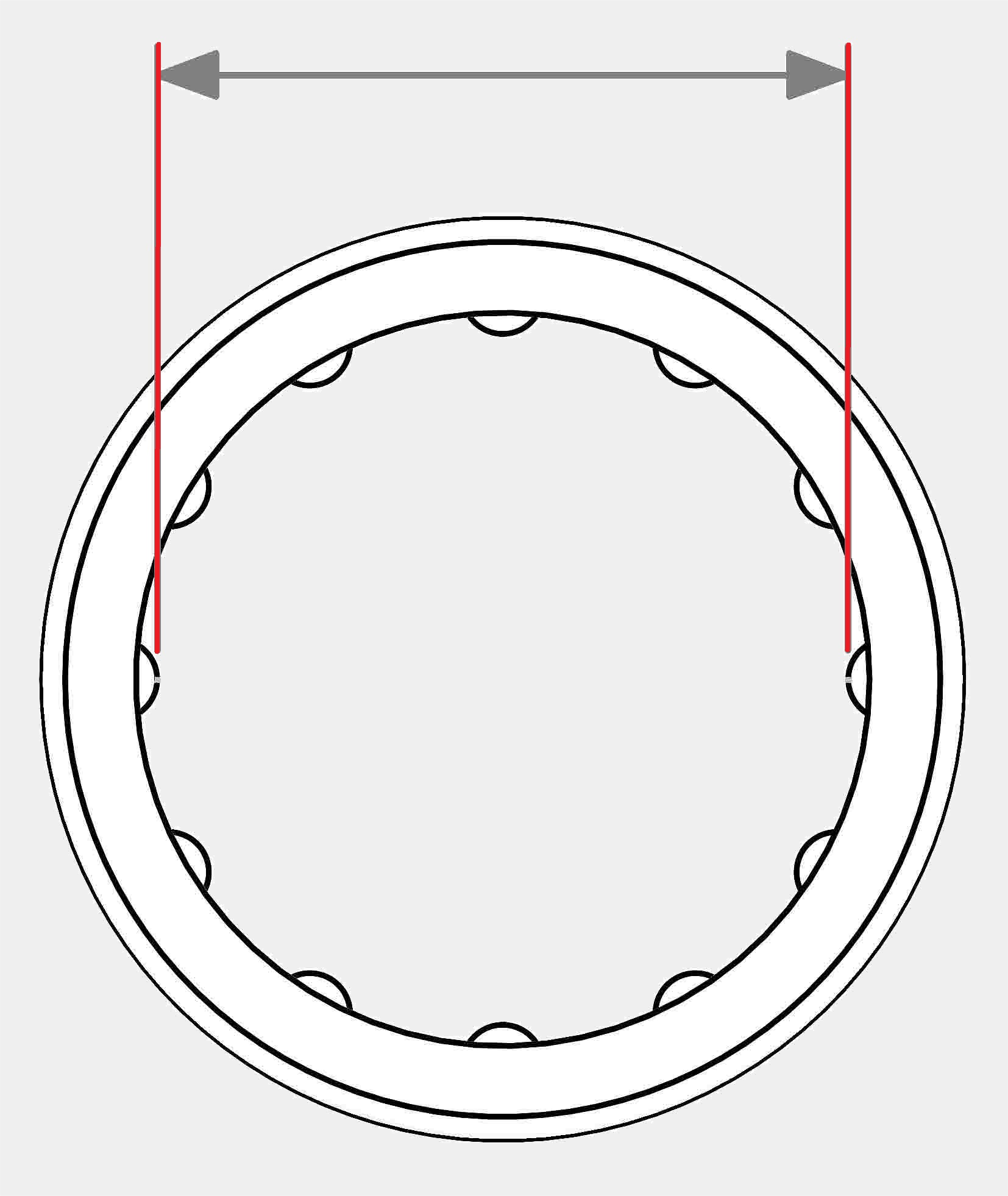

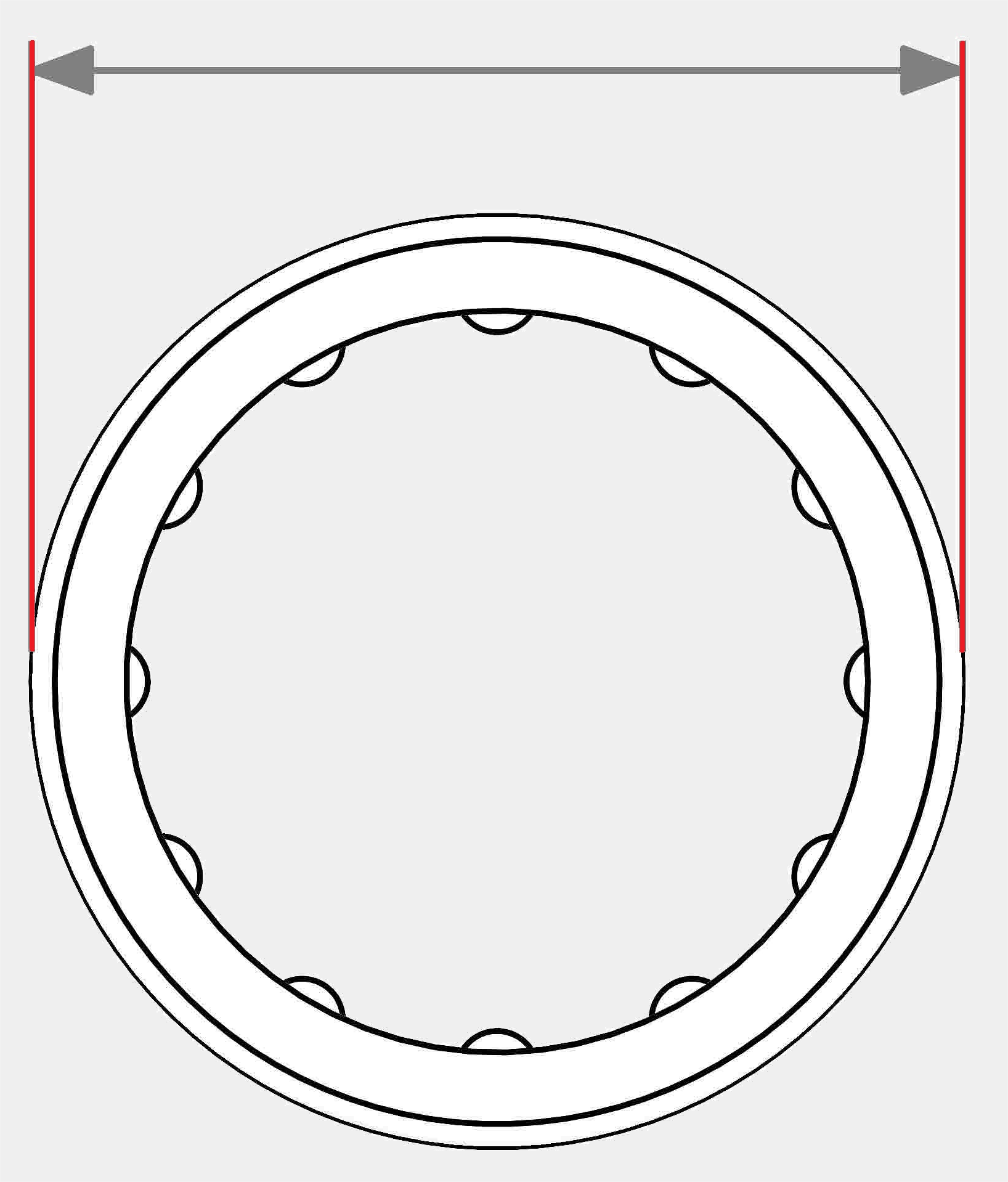

A needle bearing is a type of roller bearing that uses cylindrical rollers. What makes this cylindrical roller bearing unique is that its diameter is small compared to its length. That is why the “needles” inside these bearings resemble actual needles — hence, the name. Key components of needle bearings include:

- Needle rollers

- Inner ring (in some designs)

- Outer ring or cup

- Cage assembly (in some types)

Since they can handle both radial and thrust loads, they’re ideal for many applications. Further, they can be machined with a high degree of precision to ensure tight tolerances (strict design parameters) and optimal performance.

What’s the Difference Between Needle Bearings and Ball Bearings?

Needle bearings and ball bearings serve similar purposes: reduce friction and support loads. Aside from that, they have some pretty distinct differences in their design, use, and capacities:

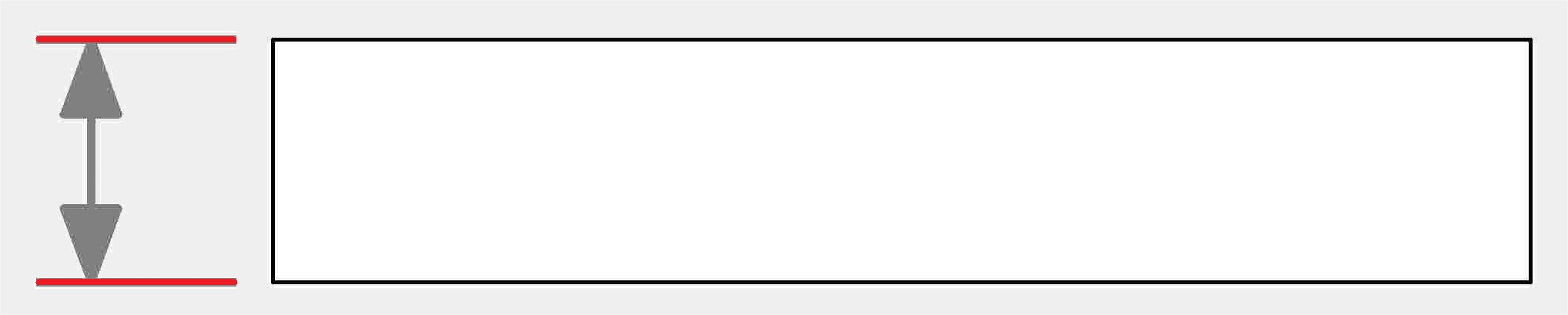

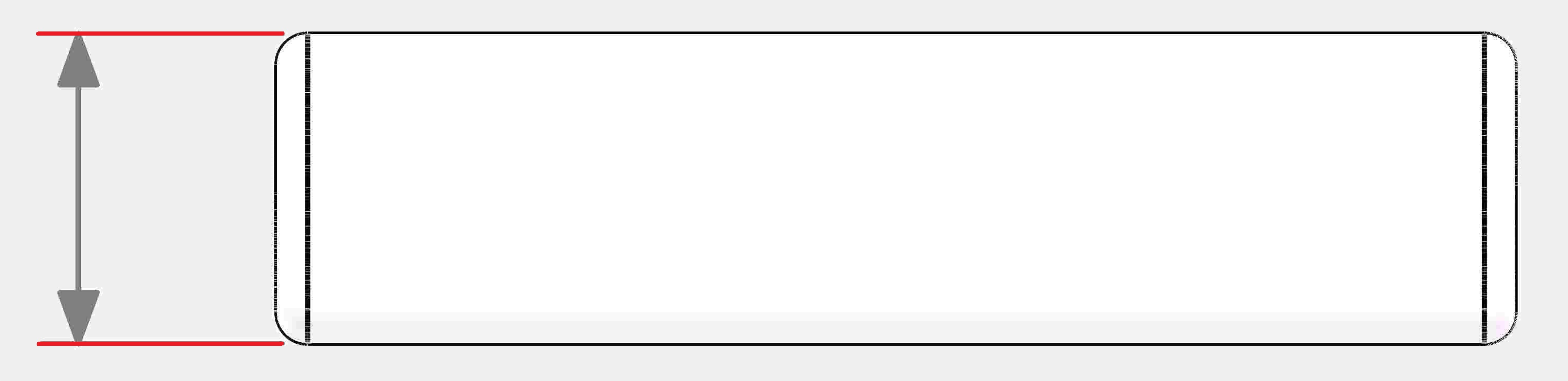

- Contact area: Compared to ball bearings, needle rollers have a larger contact area with the raceway. This enables a much higher load capacity.

- Radial space: The cross-section in needle bearings is smaller, which is why they’re ideal for applications that have a limited radial space.

- Speed capabilities: It’s important to note that ball bearings can typically handle higher speeds better than needle bearings.

- Load distribution: Where needle bearings excel is their ability to distribute heavy loads over a larger area. Thus, reducing stress on specific areas and individual components.

Types of Needle Bearings

Needle bearings come in all sizes and can be designed or machined to fit just about any situation, depending on the application. Here are a few of the most common types:

Drawn Cup

Typically used without an inner ring, drawn cup needle roller bearings have a thin-walled outer ring (i.e., cup) made of sheet steel. They’re best for applications with shafts that are hardened and grounded. This includes transmissions, printing presses, textile machinery, and much more.

Heavy Duty

Heavy duty needle bearings are specifically designed for applications that require high load carrying capacity. In most cases, they have a full complement of rollers that can withstand significant radial and axial forces. As such, you can often find them in construction equipment, mining machinery, offshore oil rigs, heavy-duty trucks, and more.

One-Way Needle-Roller Bearing

Also known as a roller clutch or one-way clutch, these bearings enable free rotation in one direction while locking in the opposite direction, like a ratcheting wrench. They're most commonly found in automotive starters, exercise equipment, conveyor systems, escalators, and many more applications.

Other types of needle rollers include:

- Cup needle roller bearings

- Thrust needle roller bearings

- Loose needle rollers

- Needle roller and cage assemblies

It’s important to note that while support rollers (i.e. track rollers) and cam followers, are both based on needle roller bearings, they are slightly different in their designs and use cases.

What Needle Bearings Are Typically Used For

Due to their compact design and ability to handle heavy-duty loads, these parts have many applications across industries. Some of the most common uses include:

Automotive Industry

- Transmissions

- Engines (e.g., rocker arm pivots)

- Steering systems

- Driveshafts

Industrial Machinery

- Gearboxes

- Compressors

- Pumps

- Conveyors

Consumer Appliances

- Power tools

- Home appliances

- Refrigerator compressors

- Dishwasher spray arms

- Washing machine drums

- Dryer tumbler supports

Advantages of Needle Bearings

Needle bearings are the preferred choice for many applications, because they have the following qualities:

- High load carrying capacity

- Compact design with low sectional height

- Ability to handle both radial and axial loads

- Suitable for high speeds

- Low friction and smooth operation

- Long service life when properly maintained

Tips for Selecting the Right Needle Bearing

When choosing an ideal needle bearing, you should consider the needs of your project. This includes specifications like:

- Radial and axial load requirements

- Speed capabilities

- Space constraints

- Lubrication needs

- Operating environment (temperature, contamination)

- Shaft hardness and surface finish

- Required service life

- Misalignment tolerance

At LILY Bearing, we have an extensive catalog (more than 60,000 types of roller bearings) and many technical resources to ensure you select the best bearing for your needs.

Installation and Maintenance Best Practices

Generally, needle bearings are only as good as their installation and routine maintenance. That’s especially true when it comes to maximizing their performance and lifespan. A few maintenance and installation best practices to pay attention to include:

- Ensure clean installation environment

- Use appropriate tools and techniques for mounting

- Provide adequate lubrication (oil or grease)

- Regularly inspect for wear and damage

- Monitor operating conditions (load, speed, temperature)

- Replace bearings at recommended intervals or when signs of wear appear

Needle bearings are designed to be durable, but they can wear out over time. However, with regular maintenance and proper lubrication, you can extend their service life by a significant margin.

Why Choose LILY Bearing for Needle Bearings

At LILY Bearing, we offer a comprehensive range of high-quality needle bearings to meet diverse industrial needs. We’re considered among the best bearing provider because of our:

- Vast selection of nearly 100k bearing options, which includes both metric and imperial sizes.

- More than 20 years of industry experience and product knowledge.

- Strict adherence to quality assurance, ensuring all bearings are manufactured with premium bearing steel and to strict tolerances.

- Ability to manufacture (at scale if necessary) custom bearings to fit your exact requirements.

- Responsive and knowledgeable customer care and technical assistance teams.

Whether you need standard needle roller bearings, specialized types like stud type cam followers, or more customized solutions, LILY Bearing has you covered.

Are you ready to find the perfect needle bearing for your project? Browse our wide range of bearing products today.