- Equivalent to Manufacturer :

- AMI

Mounted Bearings

6551 ProductsWhat Are Mounted Bearings?

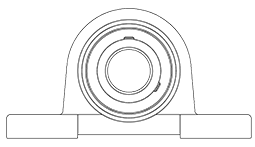

Mounted bearings are precision elements that house rolling bearings and support rotating shafts, whether they're bolted onto a machine frame or any other form of a substructure. They provide the functionality of a bearing and the stability of a housing unit, combining both components into a single unit.

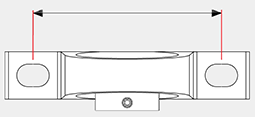

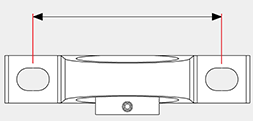

Bearing Housing and Bearing Unit: The Backbone of Mounted Bearings

- The bearing housing is a critical component that supports the entire bearing unit. It protects the bearing, maintains its position, and offers a means to secure the unit within machinery.

- The bearing unit itself is a comprehensive, integrated system that simplifies the process of using and maintaining bearings in industrial settings.

Mounted Bearing Types

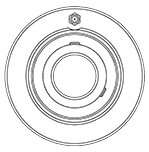

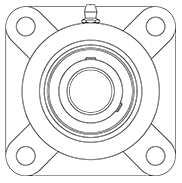

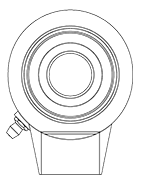

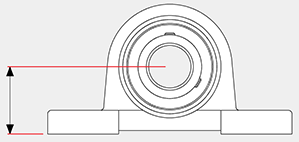

Mounted bearings come in several forms to suit different mechanical needs and operational environments:

- Flange Mounted Bearings: These bearings are designed to be mounted on external surfaces and are typically available with two, three, or four mounting holes.

- Mounted Ball Bearings: Known for their versatility and capacity for handling both radial and axial loads.

- Mounted Linear Bearings: Designed to provide free motion in one direction, these are key components in linear motion systems.

- Mounted Roller Bearings: Suited for applications that require heavy-duty support with minimal friction.

- Mounted Sleeve Bearings: These are known for their simplicity and durability, often used in applications where high load capacity is needed.

- Mounted Tapered Roller Bearings: Ideal for applications requiring the support of a combination of radial and axial loads.

Each type of mounted bearing is designed to accommodate a specific set of uses and operational criteria, including the type of rolling element, the design of the bearing housing, and the method of shaft locking.

Key Benefits of Mounted Bearings

Mounted bearings are a boon for machinery, providing a host of benefits that streamline operations:

- Streamlined Installation: Ready to go straight from the package, mounted bearings simplify setup, eliminating complex assembly and saving time.

- Built for Endurance: Made from materials like cast iron and stainless steel, these bearings withstand tough conditions and are ideal for both industrial and outdoor use.

- Hassle-Free Upkeep: With user-friendly features like grease fittings, they make maintenance a breeze, crucial for longevity and optimal performance.

- Economical: They’re a cost-saver, negating the need for precise housing machining and reducing long-term maintenance expenses.

- Compact Efficiency: Their all-in-one design conserves space, an essential aspect in tight or complex machinery layouts.

- Strong Load Support: Designed to manage heavier loads, such as with mounted roller and tapered roller bearings, they maintain efficiency and precision.

- Minimized Machine Stops: Quick to replace, they cut down on machinery downtime, ensuring consistent operation with little pause for repairs.

- Protection Against Contaminants: With built-in sealing systems, they shield internal parts from dirt and moisture, enhancing machine reliability.

- Automatic Alignment: Features like self-aligning spherical roller bearings adjust to correct misalignment, vital for maintaining machinery precision.

Applications of Mounted Bearings

Mounted bearings are commonly used in applications, such as:

- Conveyors and Rollers: They help keep materials moving smoothly in factories and warehouses.

- Farm Equipment: Durable enough for heavy farm machinery, mounted bearings handle dirt and weather changes well.

- Food Processing: In food production, they meet cleanliness standards and resist water damage during cleaning.

- Metalwork Machines: They support the heavy-duty and precise needs of machines that cut and shape metal.

- Vehicle Manufacturing: Mounted bearings keep car assembly lines running accurately and efficiently.

- Packaging Machines: They ensure packaging machines operate smoothly, keeping up with production demands.

- Printers and Copiers: Small but mighty, these bearings allow office machines to run quietly and reliably.

- Medical Equipment: Accuracy is vital, and mounted bearings help medical devices like scanners work precisely.