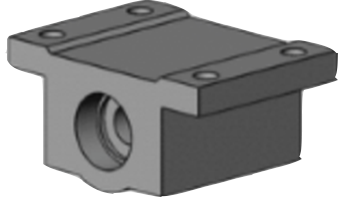

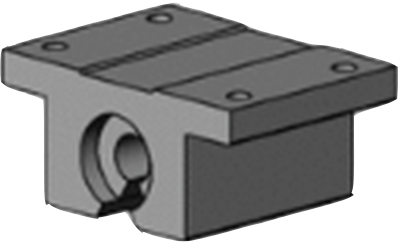

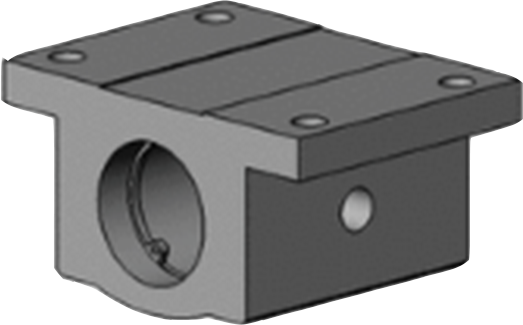

Linear Bearings

835 ProductsWhat is a Linear Bearing?

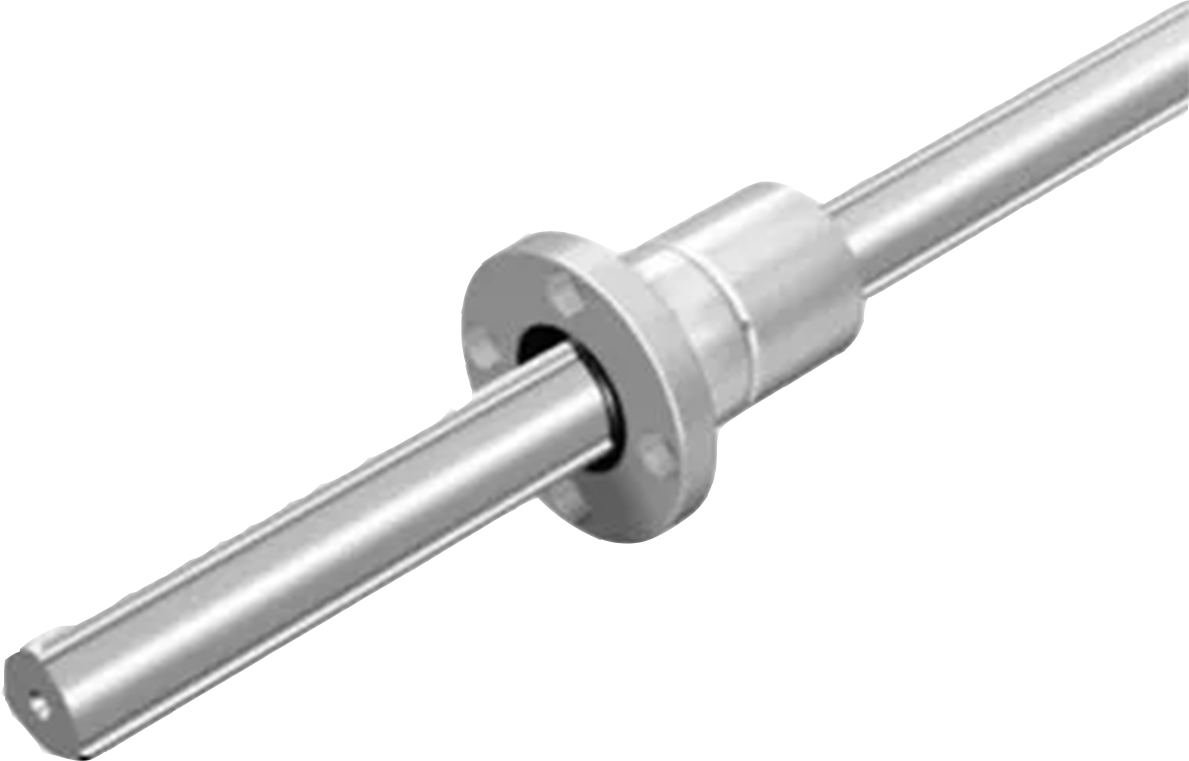

Linear bearings are a type of bearing designed to provide motion in a straight line. They are used in a variety of applications, from manufacturing equipment to aerospace systems. Linear bearings are an essential component in many mechanical systems, as they enable smooth, precise movement.

Types of Linear Bearings

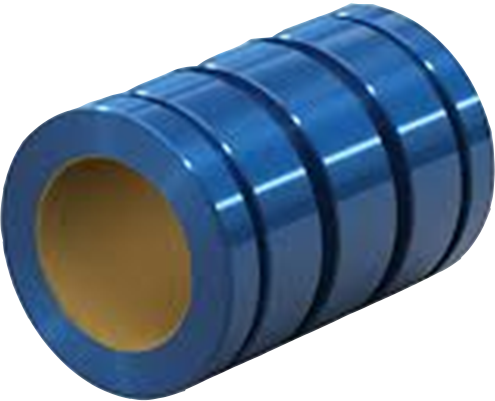

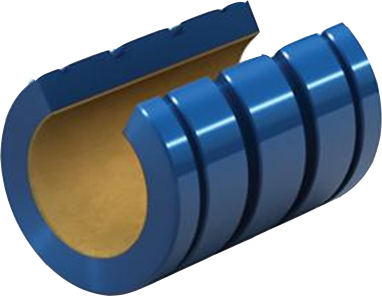

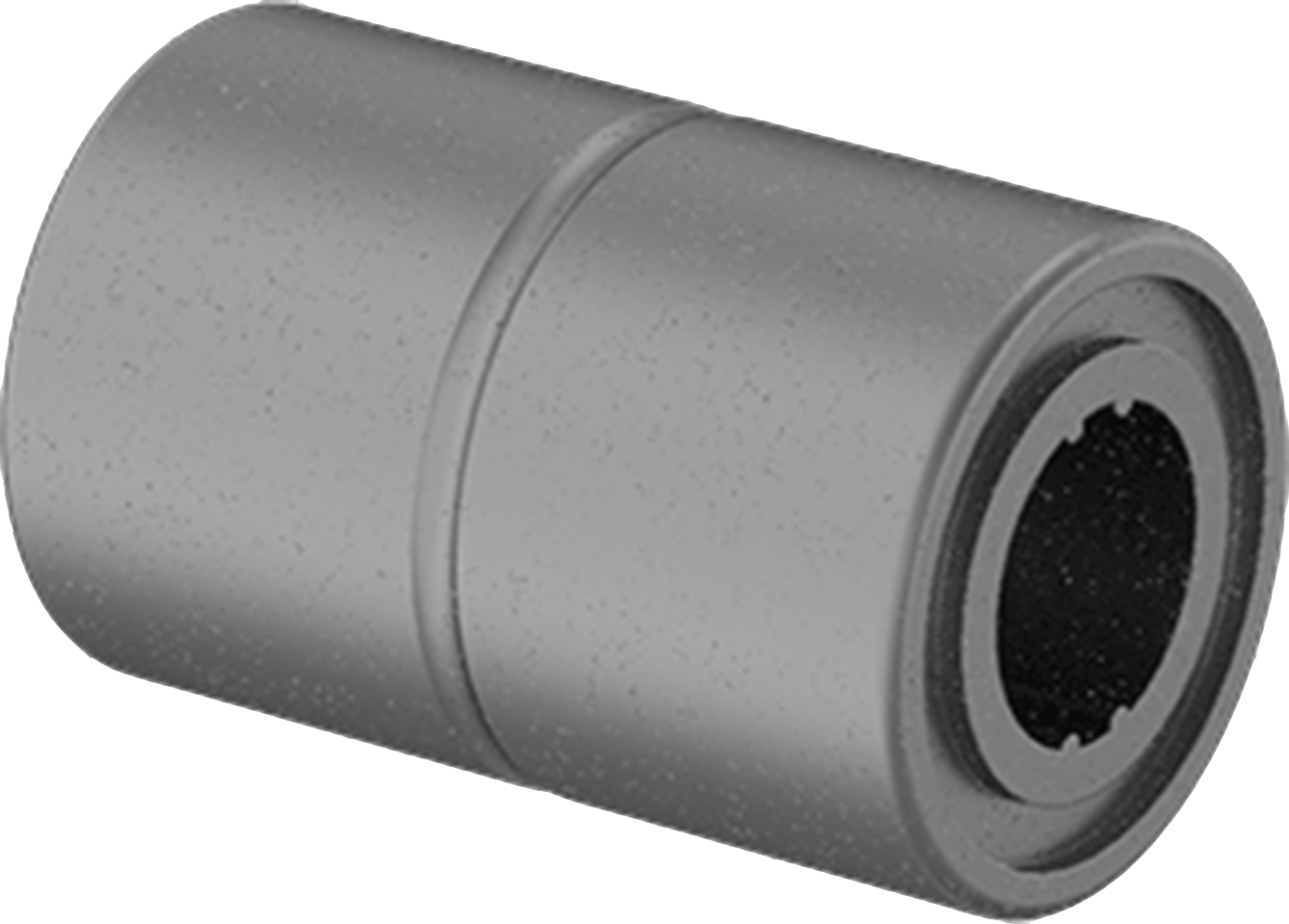

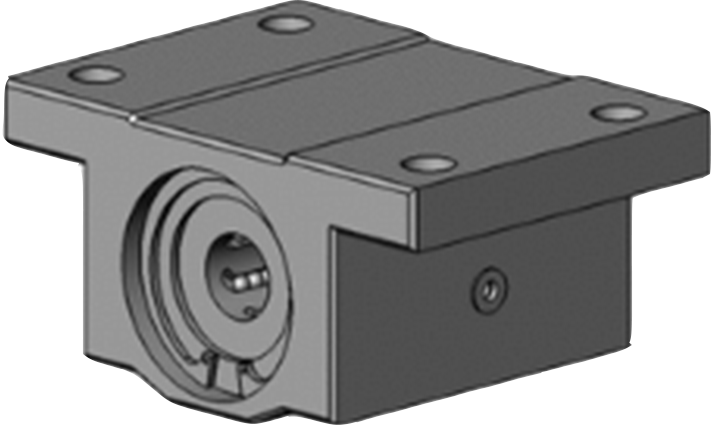

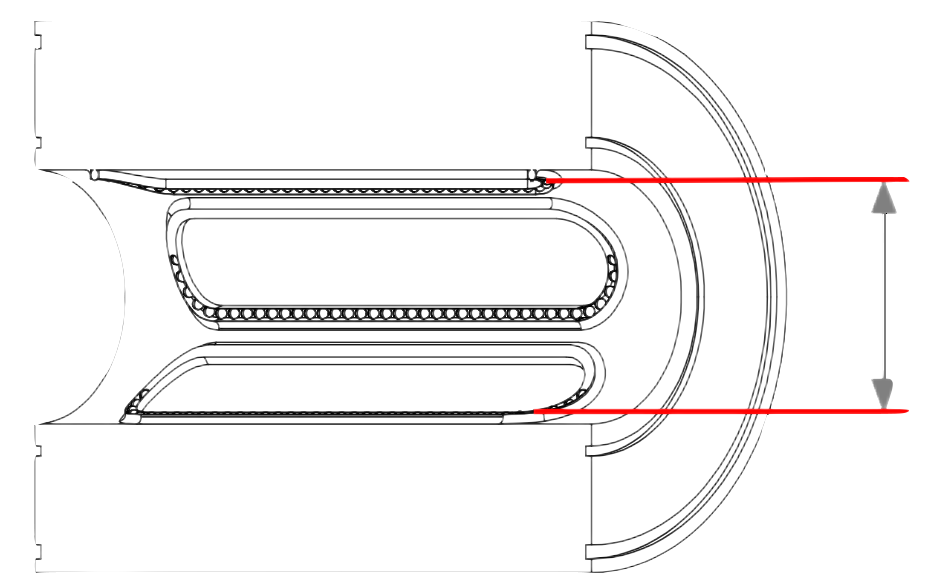

There are several types of linear bearings available, including ball bearings, roller bearings, and sleeve bearings. Each type has its unique characteristics and advantages, depending on the application requirements. Ball bearings are the most common type and are best suited for high-speed, low-load applications. Roller bearings are ideal for heavy loads and are often used in conveyor systems. Sleeve bearings are self-lubricating and have a low coefficient of friction, making them suitable for low-speed, high-load applications.

Benefits of Linear Bearings

Linear bearings offer several benefits, including high accuracy, low friction, and smooth motion. They are designed to provide precise positioning and are often used in applications that require high precision. Linear bearings also have low friction, which minimizes wear and tear on the system and reduces energy consumption. Finally, the smooth motion provided by linear bearings ensures that the system operates quietly and efficiently.

Applications of Linear Bearings

Linear bearings are used in a wide range of applications, including robotics, manufacturing equipment, aerospace systems, and medical devices. They are essential components in systems that require precise positioning, smooth motion, and low friction. Linear bearings are also used in linear motion guides, linear actuators, and linear stages, where they play a critical role in the performance of these systems.

Installation and Maintenance of Linear Bearings

Linear bearings require careful installation and regular maintenance to ensure optimal performance. During installation, it’s important to pay attention to external loading conditions such as axial thrust force which can affect motion quality. Additionally, make sure all components remain aligned and perform as expected.

Regular maintenance also helps keep the system in peak condition. This includes inspecting all components for signs of wear or damage, lubricating regularly, cleaning regularly and replacing worn or defective parts. Proper care of linear bearings helps extend their life expectancy and ensures reliable operation over time.

Why LILY Bearing?

LILY Bearing is a great choice for those looking for high-quality, affordable linear bearings.

◆Wide range of products to fit various applications.

◆Quality assurance through rigorous testing and inspection.

◆Competitive pricing for affordability.

◆Customization options for unique needs.

◆Excellent customer service with knowledgeable professionals.

◆Fast delivery times and global distribution network for timely delivery.

In summary, LILY Bearing is a reliable partner for all your linear bearing needs, offering quality products, customization options, and excellent customer service at an affordable price. In addition to the products shown on the page, we also offer THK tequivalents.