Chrome Steel vs. Stainless Steel Bearings: Which Do You Need?

Bearings are crucial for precise movement and reliability in mechanical systems. The type of material affects how well and how long a bearing works. In this blog, we'll look at chrome steel vs stainless steel bearings to help you choose the best option for your needs.

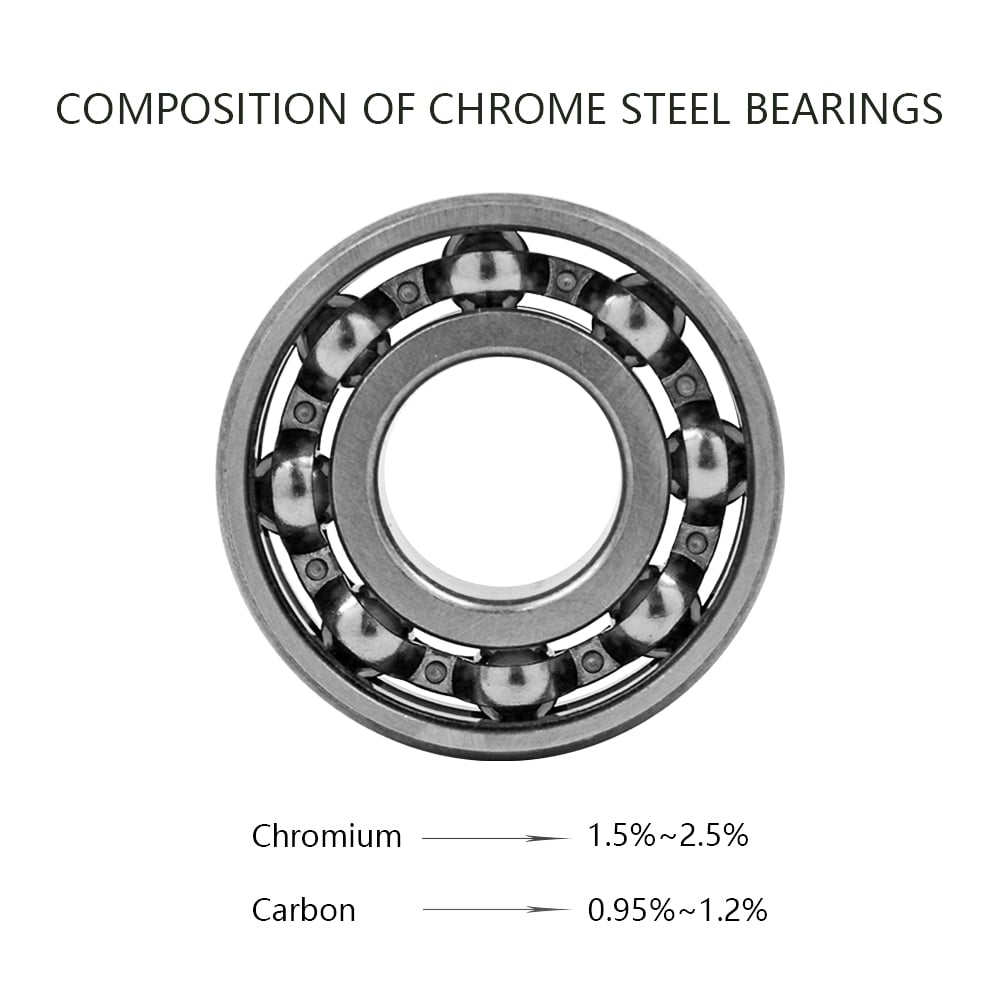

Understanding Chrome Steel Bearings

Chrome steel bearings are made from chromium steel, which contains 1.5% to 2.5% chromium and 0.95% to 1.2% carbon. This high-carbon composition enhances hardness and durability, making chrome steel bearings ideal for applications requiring high wear resistance and strength.

Key Properties of Chrome Steel Bearings

- High Load Capacity: Chrome steel bearings can withstand both heavy loads and impact forces, making them suitable for demanding applications.

- High Hardness and Wear Resistance: Due to its high carbon content, chrome steel can be hardened through heat treatment, achieving a much higher hardness level compared to many other steels. This results in excellent wear resistance, ensuring that the bearings maintain their integrity and performance under friction and continuous use.

- Fatigue Resistance: Chrome steel bearings are capable of handling stress and load changes repeatedly without failing, making them highly reliable for applications involving high speeds or varying loads.

However, it's important to note that while chrome steel bearings offer significant hardness and wear resistance, they are less resistant to corrosion compared to stainless steel bearings. Therefore, they are best used in environments where exposure to moisture or corrosive materials is minimal unless they are adequately protected or sealed.

In summary, chrome steel bearings are highly valued in the engineering and manufacturing sectors for their strength, durability, and capacity to handle high loads. Their robustness makes them a preferred choice in a range of applications, from automotive to industrial machinery, where performance and longevity are critical.

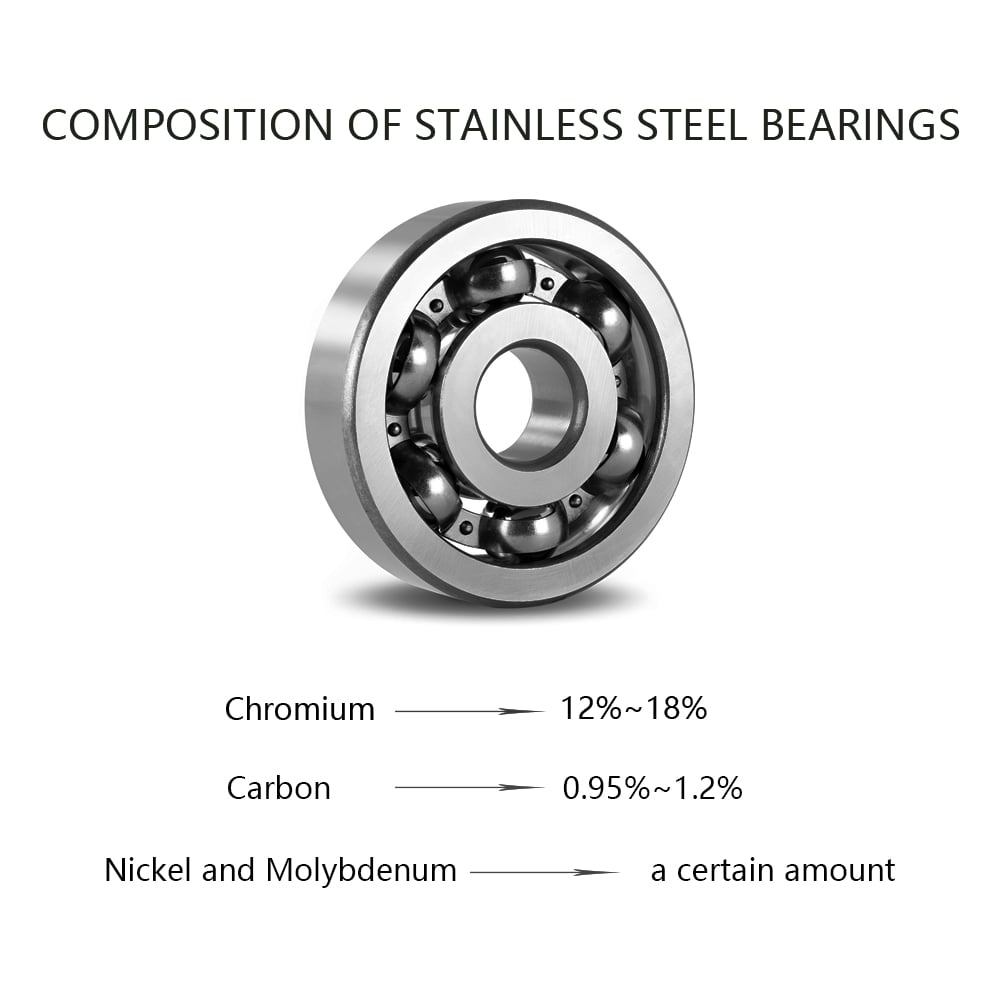

Understanding Stainless Steel Bearings

Stainless steel bearings are crafted from a corrosion-resistant alloy that's perfect for demanding applications. This alloy primarily includes chromium—at least 10%—which is key to its ability to resist rust. Other critical elements like nickel and molybdenum are added to enhance its mechanical properties and strength. The 440C grade is particularly popular for bearings due to its higher carbon content, striking a balance between toughness and corrosion resistance.

Composition of Stainless Steel Bearings

- Chromium (12-18%): Boosts resistance to oxidation and corrosion.

- Carbon (0.95-1.20%): Increases hardness for better wear and deformation resistance.

- Nickel and Molybdenum: Add to the alloy’s overall strength and durability.

Advantages of Stainless Steel Bearings

- Corrosion Resistance: Stainless steel bearings excel in environments that are prone to moisture and corrosive substances, making them highly durable under challenging conditions.

- Hygienic Properties: The non-porous nature of stainless steel makes it ideal for applications where sanitation is a priority, such as in food processing or medical equipment.

- High Temperature Tolerance: They can handle up to 300°C with the right bearing lubricant, outperforming chrome steel in high temperatures.

- Longevity: The initial cost of stainless steel bearings might be higher, but their durability and resistance to harsh conditions mean they often last longer than other types of bearings, reducing the need for frequent replacements.

- Low Maintenance Needs: The rust and corrosion resistance of stainless steel bearings translate to lower maintenance, helping to minimize downtime and save on upkeep costs in critical operations.

Stainless steel bearings are an excellent choice for applications requiring high durability and minimal maintenance, such as in the marine, food, and pharmaceutical industries. Their ability to withstand harsh conditions without compromising performance makes them indispensable in settings where failure is not an option.

Click here to learn more about Characteristics, Uses and Advantages of Stainless Steel Bearings.

Comparing Chrome Steel and Stainless Steel Bearings

Choosing the right bearings for your application involves understanding the differences between chrome steel and stainless steel bearings in terms of performance, environmental suitability, and costs.

Performance Comparison

Here’s a quick comparison of chrome steel vs stainless steel bearings based on key performance metrics:

| Property | Chrome Steel Bearings | Stainless Steel Bearings (440C) |

| Load Capacity | High | Moderate |

| Hardness | Very High | High |

| Wear Resistance | Excellent | Good |

Environmental Suitability

The environment in which the bearing operates greatly influences the choice between chrome steel and stainless steel.

- Humidity and Corrosion: Stainless steel bearings are ideal in moist or corrosive environments like marine settings or chemical plants due to their excellent corrosion resistance. Chrome steel is less resistant and may need additional treatment to avoid rust.

- Extreme Temperatures: Stainless steel bearings also perform well under extreme temperatures, maintaining their integrity in both hot and cold environments.

Cost Considerations

Cost is an important factor in choosing the right bearing.

- Initial Costs: Chrome steel bearings are generally more affordable upfront due to lower material and production costs.

- Long-Term Costs: Though stainless steel bearings may cost more initially, their durability and minimal maintenance needs can lead to lower overall costs in harsh environments.

When to Choose Chrome Steel Bearings

Chrome steel bearings are an excellent choice for many industrial applications due to their robustness and cost-effectiveness. Here's a brief overview of the scenarios where these bearings are most advantageous:

| Scenario | Suitability of Chrome Steel Bearings |

| High Load Requirements | Excellent for handling high loads due to their strong and durable structure. |

| High-Speed Applications | Ideal for machinery that operates at high speeds, thanks to their ability to withstand dynamic forces and stress. |

| Non-Corrosive Environments | Best used in environments with minimal exposure to moisture or corrosive substances, as they are less resistant to corrosion. |

| Cost-Sensitive Projects | A cost-effective option for projects with tight budgets, providing good quality at a lower price. |

| Periodic Maintenance Possible | Suitable for settings where regular maintenance can be conducted to prevent rust and wear. |

When to Choose Stainless Steel Bearings

Stainless steel bearings are highly valued for their corrosion resistance and durability, making them an ideal choice for specific environments and applications. Below, we provide guidance on when selecting stainless steel bearings is most advantageous:

Stainless steel bearings excel in situations where standard bearings might fail due to harsh conditions. Here's a clear table outlining the ideal scenarios for choosing stainless steel bearings:

|

Scenario |

Suitability of Stainless Steel Bearings |

|

Corrosive Environments |

Perfect for areas exposed to chemicals, moisture, or saline environments where corrosion resistance is crucial. |

|

Ideal due to their ability to withstand washdown procedures and prevent contamination. |

|

|

Preferred in medical devices and equipment for their hygienic properties, ensuring they can be sterilized without degradation. |

|

|

High and Low Temperature Extremes |

Excellent for applications experiencing extreme temperatures, maintaining performance without structural compromise. |

|

Low Maintenance Requirements |

Suitable for applications where regular maintenance is difficult, as their corrosion resistance minimizes the need for frequent upkeep. |

|

Skateboarding |

Skateboard bearings made from stainless steel are ideal for riders who often face humid or wet conditions, as they resist corrosion much better than traditional chrome steel bearings. |

Which is Best? Navigating the Decision

Choosing between chrome steel and stainless steel bearings hinges on understanding your specific needs. Here’s a concise guide to making the right choice:

Performance Needs

- High Load and Speed: Choose chrome steel for high load capacity and speed.

- Wear Resistance: Chrome steel is better for applications with significant wear and tear.

Environmental Conditions

- Corrosive Environments: Stainless steel is essential in moist or chemically aggressive areas due to its corrosion resistance.

- Temperature Extremes: Stainless steel excels in extreme temperatures.

Budget Constraints

- Initial Cost: Chrome steel is more budget-friendly upfront.

- Long-Term Value: Stainless steel, though costlier initially, may reduce long-term expenses with fewer replacements and less maintenance.

Maintenance Requirements

- Regular Maintenance: If feasible, chrome steel can be an effective choice.

- Low Maintenance: Stainless steel is preferable in low-maintenance scenarios.

Your decision should balance these factors to match the bearing type with your application’s demands, ensuring optimal performance and cost-efficiency.

Global Standards and Grades

Understanding the standards and grades used globally can ensure compatibility and performance. Here’s an overview of the standard grades in different regions:

|

Country/Standard |

Chrome Steel Grade |

Stainless Steel Grade |

|

USA (AISI/ASTM) |

52100 |

440C |

|

Europe (EN) |

100Cr6 |

X105CrMo17 (1.4125) |

|

Japan (JIS) |

SUJ2 |

SUS440C |

Conclusion

When choosing between chrome steel vs stainless steel bearings, consider your specific needs. Opt for chrome steel in high-load, maintainable environments and stainless steel in corrosive, low-maintenance settings. At LILY Bearing, we offer a wide selection of both chrome and stainless steel bearings, including options with stainless steel bearing passivation for enhanced corrosion resistance. Visit LILY Bearing to find your ideal industrial bearings.

Keep Learning