Cancel

NF350AR0

Price $ 5035.14

Number

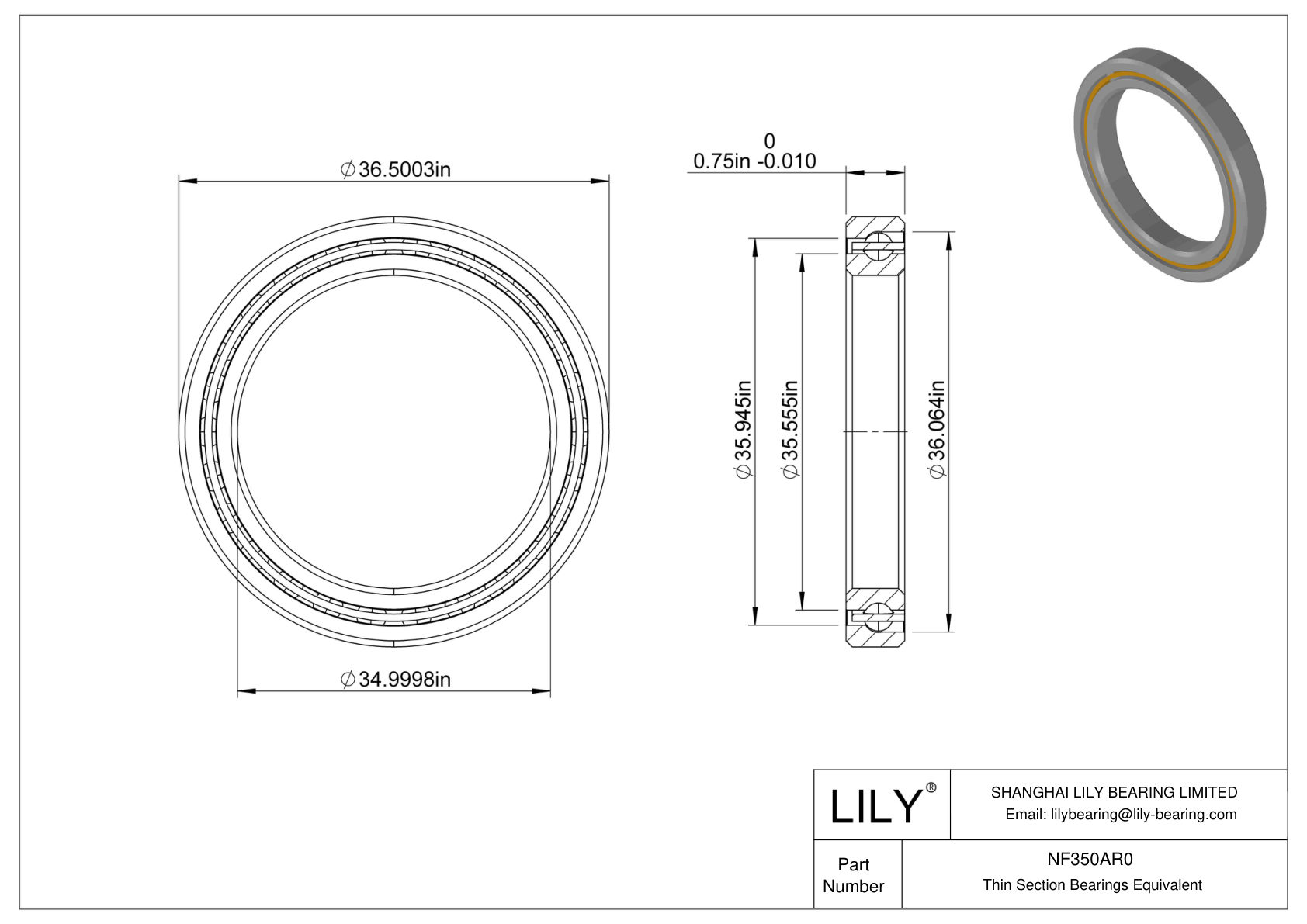

| Part Number | NF350AR0 |

Brand: LILY  | |

Equivalent: KAYDON |

| System of Measurement | Inch |

| Bearing Type | Ball |

| For Load Direction | Angular Contact |

| Contact Angle | 30° |

| Construction | Single Row |

| Surface | Chromium Plating |

| Seal Type | Open |

| Thin Section Bearings Type | Endura-kote Plated Bearings |

| Series | NF 3/4" x 3/4" |

| Bore Dia | 35" |

| Bore Dia Tolerance | -0.0020"– 0" |

| Outer Dia | 36.5" |

| Outer Dia Tolerance | -0.0020"– 0" |

| Width | 0.75" |

| Width Tolerance | +.000 –.010" |

| External Diameter On Inner Ring | 35.555" |

| Internal Diameter On Outer Ring | 35.945" |

| External Diameter On Outer Ring | 36.064" |

| Ring Material | Chrome Steel |

| Ball Material | Chrome Steel |

| Cage Material | Brass |

| Dynamic Radial Load | 11382 lbf |

| ISO radial 1 | 14653 Ibs |

| Static Radial Load | 48380 lbf |

| Static Thrust | 32580 lbs |

| Static Moment | 139700 lbs |

| Lubrication | Lubricated |

| Shaft Mount Type | Press Fit |

| Temperature Range | -30°C to 110 °C |

| ABEC Rating | ABEC-1 |

| Radial Clearance | 0.0000 – 0.0005" |

| RoHS | Compliant |

| Weight | 14.6 lbs |

1 ISO Radial ratings are calculated per ISO 281:1990. They are included for comparison only.

INTERCHANGE

The LILY bearing part series NF350AR0 is a potential replacement for these common bearing part numbers.

LILY

KAYDON

RBC

LNF350AR0

NF350AR0

NF350AR0*RBC

Design Features of NF350AR0 Bearing

NF350AR0 Bearing represents a specialized category of thin section bearings. It is distinguished by its unique cross-sectional geometry, which remains constant as the bore diameter increases. NF350AR0 bore dia is 35". Its out dia is 36.5". Its width is 0.75". It is manufactured to high precision standards, which is critical for applications requiring accurate and smooth motion.

What Benefits Can NF350AR0 Bearing Provide?

- Space-Saving Design: The constant, slim cross-section makes this bearing ideal for compact designs where space is limited.

- Lightweight: Its design reduces material usage, thus lowering the weight, which is crucial in aerospace and other weight-sensitive applications.

- Load Handling Capabilities: Despite its thin section, this bearing can handle a significant amount of radial, axial, and moment loads, making it versatile in various mechanical setups.

- Low Friction: It maintains low friction, which enhances the overall efficiency of the applications in which it is used.

What Can NF350AR0 Bearing Be Used for?

NF350AR0 Bearing is suitable for applications such as:

- Industrial Machinery: Used in equipment where space-saving bearings are required without compromising on load capacity.

- Aerospace Industry: In components where uniform cross-sections are essential for design integrity while maintaining weight and space efficiency.

- Robotics and Automation: Its precision and compact size make it well-suited for robotic and automated machinery.

- Medical Equipment: In devices where precision and compact design are crucial, like in advanced imaging equipment.

})