Super-Precision Contact Ball Bearings Materials

Precision spindle bearings can be manufactured from a wide range of materials. These include corrosion-resistant ring steels and hard-wearing silicon nitride (ceramic) balls. Special cage materials are also available depending on application conditions.

Bearing Rings

High-precision ball bearings are typically made from corrosion-resistant, martensitic steel alloys. As well as 9Cr18 (equal to SUS440C) lily bearings can use X65Cr13.

For spindle bearings and other demanding applications, such as medical devices and food processing, the highly corrosion-resistant nitrogen alloy steel X30CrMoN15-1 (lily bearing designation SV30) can be used. This highly-refined stainless steel has a very fine grain structure which enhances its mechanical properties.

Advantages of SV30

- Longer lifetime in comparison to conventional materials.

- Maximun corrosion resistance.

- Improved mechanical properties due to vert fine structure.

- Quiet running.

- High temperature resistance of up to 300℃.

- High chemical resistance.

SV30 Applications

- Machine tool spindles.

- Medical technology.

- Vacuum technology.

- Aerospace.

- Measurement and control technology.

- Food and beverage industry.

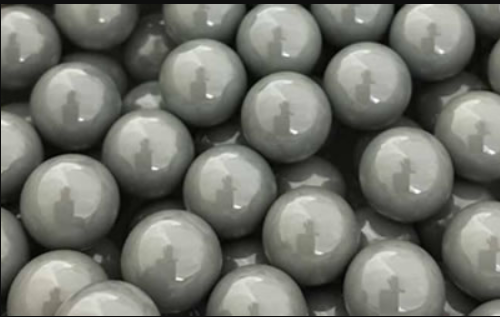

Balls for Bearings

The balls used in lily bearings are usually made of stainless steel. However,for particularly arduous applications, many of our bearings are fitted with ceramic balls made from silicon nitride (Si3N4).

Only balls of grade 3 and 5 are used for spindle bearings. These classes comply with the highest tolerances in terms of size, roundness and roughness

Bearing Cages

Lily bearings have a window cage made of fabric rein-forced phenolic as standard, the cage can be used for longer periods at temperatures of up to 100 °C.

If required, cages can also be produced from high-performance plastics such as PEEK or Torlon®. These materials are used on account of their low weight,their corrosion resistance and low friction.

The low friction properties result in reduced wear and less heat generation, which make the bearings more suited to higher speeds whilst prolonging grease service life.

Advantages of Machined Window Cages compared with Molded and Steel Cages

- High Precision

- Larger choice of materials

- Flexible designs which can be manufactured quickly

- Economic production of small to medium batches

- Longer lifetime

- High speeds