What Are Bearings and Their Functions?

Bearings are often unseen, yet they play a fundamental role in ensuring the smooth and efficient functioning of countless machines, devices, and vehicles that we use in our daily lives. Serving as a bridge between moving parts, bearings work diligently to reduce friction, facilitating seamless movement. In this blog post, we’ll delve into the heart of mechanics to answer the pivotal question: what are bearings and why are they so essential?

The Role of Bearings

Bearings, at their core, are mechanical devices that support either rotational or linear movement. Imagine two parts moving in close contact. Without bearings, these parts would grind against each other, causing wear and potentially leading to breakdowns. By reducing direct contact, and hence friction, bearings play an instrumental role in ensuring that energy transfer is efficient and wear and tear is minimized.

How Do Bearings Work

At a first glance, a bearing may seem like a simple component. However, the mechanics behind its operation are both fascinating and intricate. Bearings primarily work by creating a layer of separation between moving parts, be it through balls, rollers, or other elements. This separation ensures that friction is significantly reduced. It's also crucial to note the role of lubrication in bearing operation. Proper lubrication not only further reduces friction but also helps in heat dissipation, contributing to longer bearing life.

Types of Bearings

Bearings can be classified based on different criteria such as:

Based on Load Direction

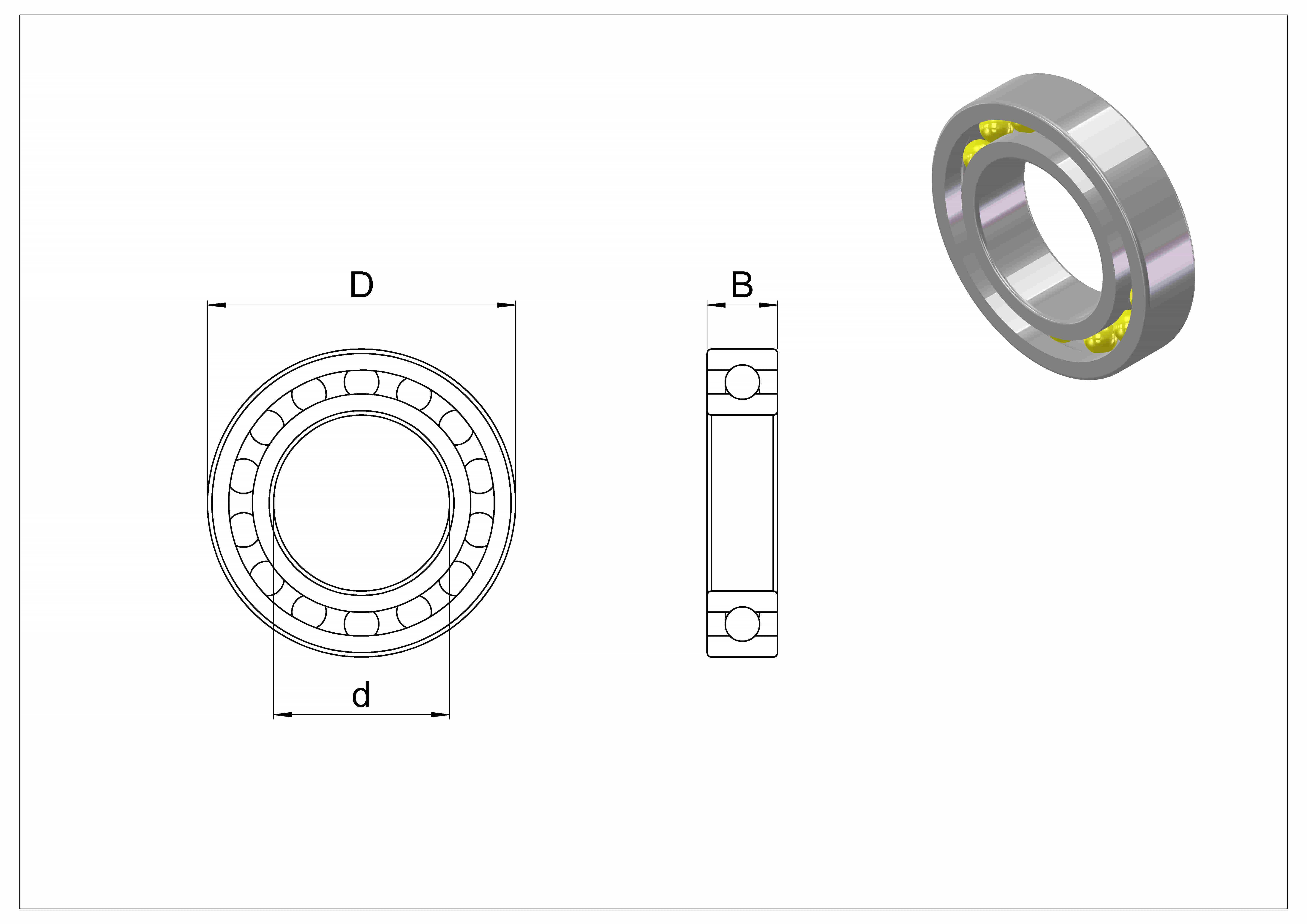

Radial Bearings (Deep Groove Ball Bearings, Cylindrical Roller Bearings, etc.): Designed primarily to support loads perpendicular to the shaft's axis; Commonly used in applications where the primary load is radial, like electric motors.

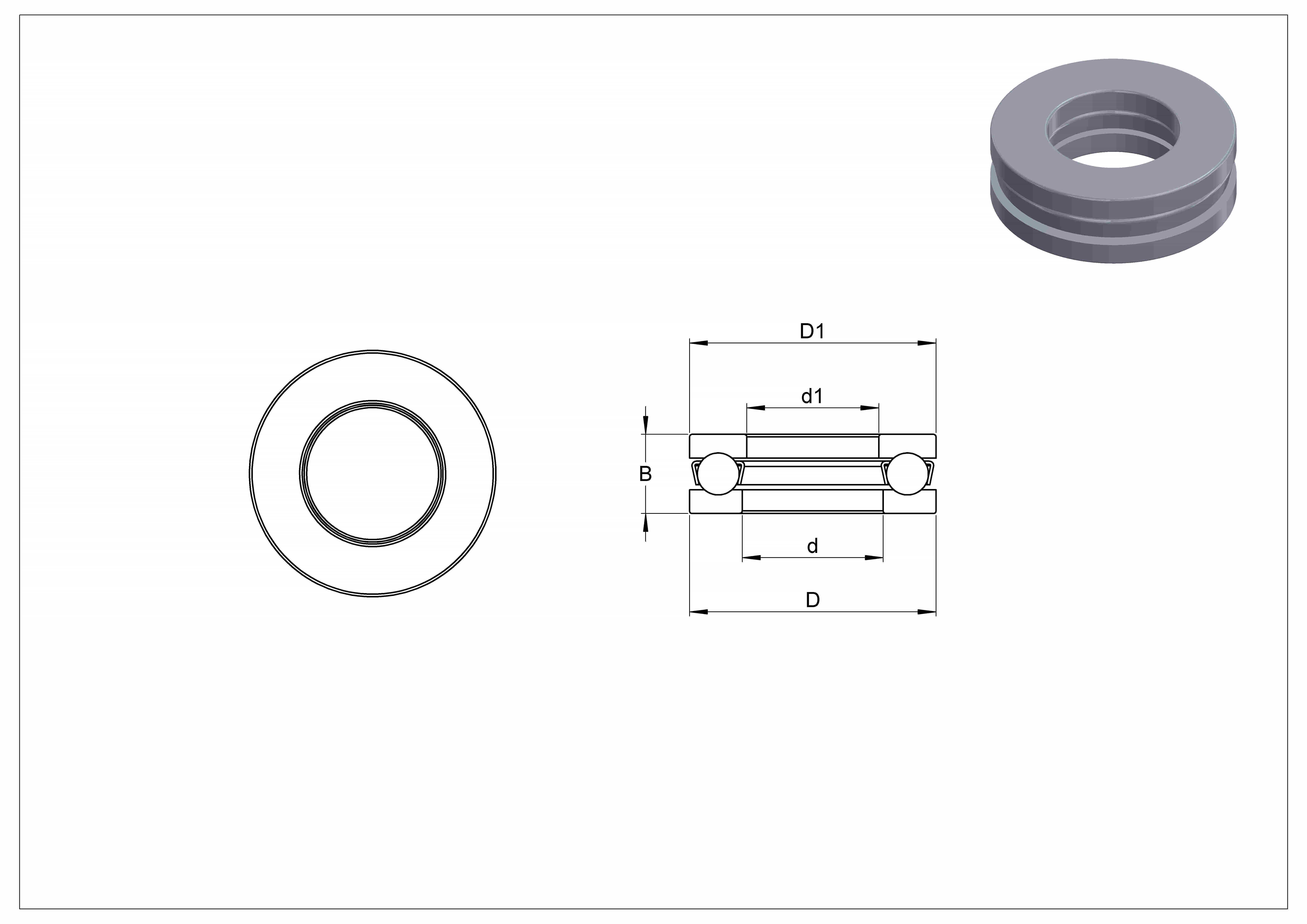

Thrust Bearings (Thrust Ball Bearings, Thrust Roller Bearings): Primarily support loads parallel to the shaft's axis. Essential in applications like automotive clutches and certain types of industrial pumps.

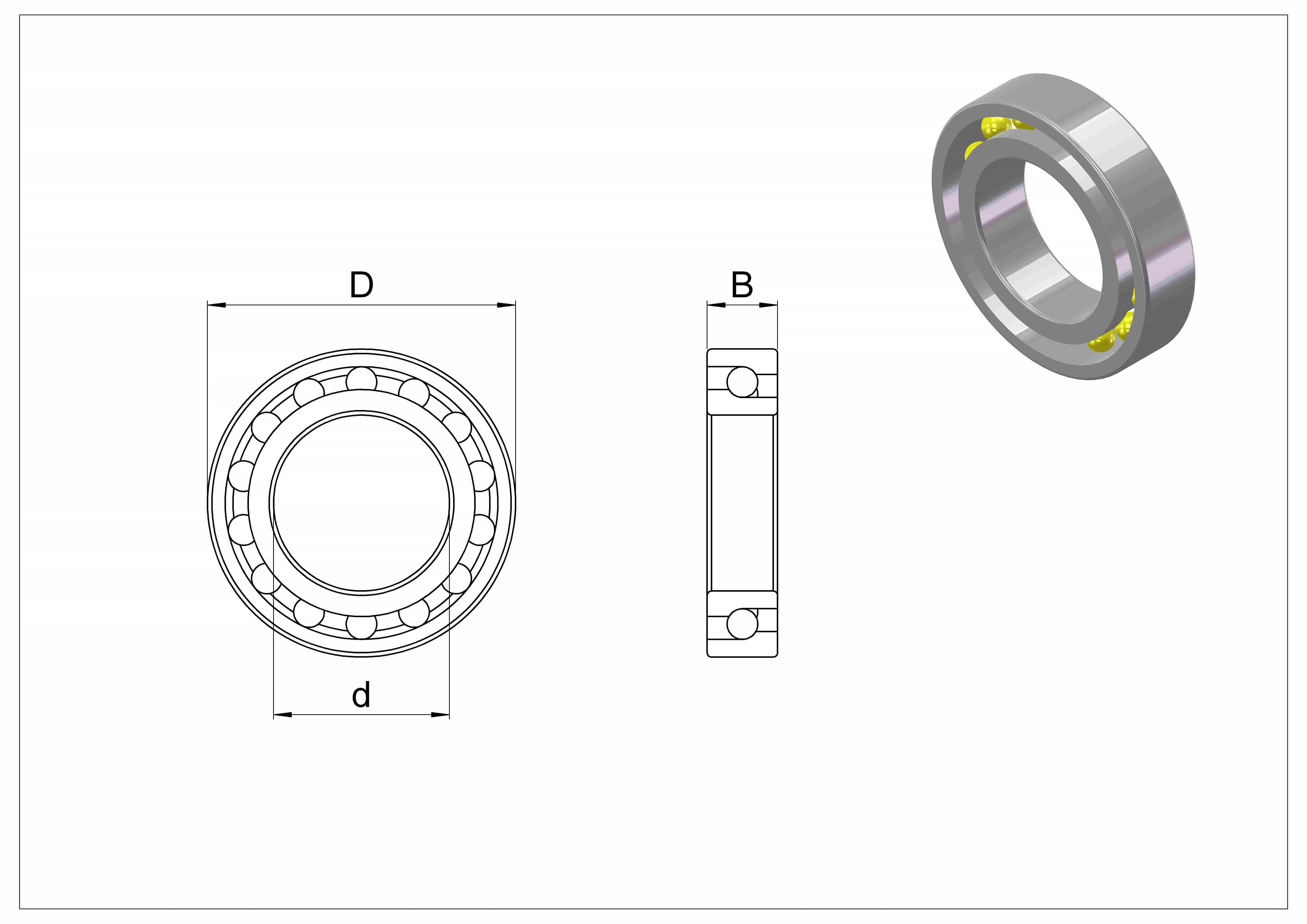

Angular Contact Bearings (Angular Contact Ball Bearings): Can support both radial and axial (thrust) loads simultaneously. Used in high-speed applications where both load types are present, such as in some high-performance car wheel hubs.

Based on Structural Design

Utilize balls as the rolling element. Offer low friction and can handle both radial and axial loads, depending on the design.

Roller Bearings (Cylindrical, Tapered, Spherical, Needle):

Use cylindrical rollers or needles as the rolling element. Generally handle higher load capacities than ball bearings due to the larger contact area.

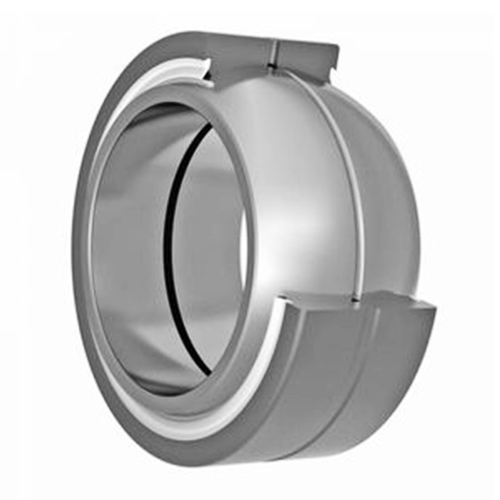

Plain Bearings (or Sleeve Bearings):

Lacks rolling elements and uses a sleeve for the shaft to slide within. Used in applications where minimal radial space and low friction are needed.

Bearings Materials: Steel and Ceramic

Steel

- AISI 52100 (High Carbon Chrome Steel): Contains approximately 1% carbon and 1.5% chromium, known for its hardness and wear resistance.

- AISI 440C Stainless Steel: A high-carbon, martensitic stainless steel known for its strength, hardness, and resistance to mild acids and corrosion. Commonly used for bearings, cutting tools, and surgical instruments.

- AISI 304 Stainless Steel: An 18/8 austenitic stainless steel, celebrated for its excellent forming and welding properties. It's widely utilized in food processing equipment and kitchen appliances.

- AISI 316 Stainless Steel: Similar to AISI 304 but enriched with molybdenum, this austenitic stainless steel offers enhanced resistance to pitting and corrosion, especially in chloride environments. Ideal for marine and pharmaceutical applications.

- AISI 420 Stainless Steel: A martensitic stainless steel with moderate corrosion resistance and the ability to be hardened through heat treatment. It's a popular choice for cutlery and surgical instruments.

Ceramic

- Zirconia (ZrO₂): Recognized for its high mechanical strength and fracture toughness, zirconia is often used in cutting tools, dental ceramics, and some high-performance bearings.

- Silicon Carbide (SiC): With superior hardness, thermal conductivity, and corrosion resistance, SiC is used in applications like mechanical seals, electronics, and high-temperature parts.

- Silicon Nitride (Si₃N₄): Offers high fracture toughness and resistance to thermal shock, making it suitable for engine parts, bearings, and cutting tools.

Advantages of Steel Bearings

Steel bearings are integral in many mechanical applications, offering a blend of durability and affordability. Their key benefits include:

- Durability: Steel bearings are known for their resilience, able to withstand high loads and resist wear, ensuring a prolonged service life.

- Cost-Effectiveness: Compared to specialty materials, steel bearings often provide a more cost-efficient solution, especially in bulk purchases.

- Thermal Conductivity: These bearings excel in dissipating heat, making them suitable for high-speed applications.

- Versatility: Available in various sizes and designs, steel bearings fit a wide range of applications.

Real-World Applications:

- Automotive: Steel bearings are essential in vehicles, ensuring smooth operations from transmission systems to wheel hubs.

- Aerospace: In aircraft, these bearings are favored for their reliability, especially in engines and landing gears.

- Manufacturing: Key machinery, from CNC machines to lathes, relies on steel bearings for consistent performance.

In essence, the widespread use of steel bearings in diverse industries underscores their reliability and efficiency.

Advantages of Ceramic Bearings

Ceramic bearings stand out for their distinct properties, offering:

- High Heat Resistance: Ceramics resist high temperatures, making the bearings suitable for heat-prone environments.

- Low Friction: This ensures smoother operations and better energy efficiency.

- Electrical Insulation & Corrosion Resistance: These bearings excel in applications requiring electrical isolation and corrosion resistance.

Industry Applications:

- High-Speed Machines: Ceramic bearings are preferred for their reduced friction.

- Aerospace: Their heat resistance and lightweight nature are invaluable.

- Chemical Processing: They withstand aggressive agents due to their corrosion resistance.

- Medical Devices: Non-conductive properties are crucial for equipment like MRI machines.

Factors Influencing Choice

Choosing between steel and ceramic bearings is not always straightforward. Factors such as the bearing load capacity required, operating speed, and specific operating conditions (like temperature) often influence the decision. The table below provides a comparative analysis of 52100 Chrome Steel bearings, stainless steel bearings and ceramic bearings:

|

Factor |

52100 Chrome Steel bearings |

Stainless Steel bearings |

Ceramic Bearings |

|

Load Capacity |

High: Renowned for handling heavy-duty tasks. |

Moderate: Good for standard to slightly heavy-duty tasks. |

Moderate to High: Depending on type and design. |

|

Speed |

Good: Handles standard speeds reliably. |

Good: Suitable for many standard applications. |

Ideal for high-speed applications due to low friction. |

|

Operating Conditions |

Standard: Performs well under typical conditions, but prone to corrosion in humid or salty environments. |

Superior to Chrome Steel: Resistant to rust and corrosion, especially in wet or corrosive settings. |

Best: Resists high temperatures, corrosion, and has minimal thermal expansion.

|

|

Cost & Maintenance |

Moderate: Common and widely available, with standard maintenance needs. |

Slightly higher than Chrome Steel: Given its anti-corrosive properties. |

Highest: Initial cost is high, but longer lifespan and less maintenance in specific environments can justify the price. |

Conclusion

Bearings, whether made of steel or ceramic, play a fundamental role in many mechanical systems. When contemplating "what are bearings" and their significance, it becomes clear that their role in minimizing friction and facilitating movement is indispensable. Here at Lily-Bearing, we grasp these intricacies and are dedicated to guiding you in making the optimal choice tailored to your specific requirements.

Keep Learning