Bad Cam Follower Symptoms

Understanding Bad Cam Follower Symptoms

The engine, often referred to as the heart of a vehicle, depends on several components to run smoothly. Among these, the cam follower regulates the position of the Camshaft by engaging with the CAM lobe, ensuring that the right amount of fuel is delivered for combustion. It plays an integral role in the fuel delivery system, influencing the overall engine performance. Recognizing bad cam follower symptoms promptly is paramount for maintaining an engine's efficiency and longevity.

Common Symptoms of a Bad Cam Follower

Intermittent Loss of Power

A bad cam follower can compromise valve timing and operation. As it deteriorates, the precise opening and closing of the engine's valves become disrupted, leading to an imbalanced air-fuel mixture and incomplete combustion. Especially during acceleration, when the engine demands optimal performance, this inefficiency results in noticeable power loss. Proper valve function is crucial for maintaining peak engine output, and a failing cam follower directly impedes this, reducing acceleration capability.

Misfiring

A failing cam follower can disrupt valve timing, leading to an imbalanced air-fuel mixture in the combustion chamber. This causes incomplete combustion or non-ignition, resulting in engine misfires. Faulty cam followers can also compromise valve sealing, further contributing to misfire issues.

Such misfires manifest as jolts or judders when the engine is running. Continuous misfiring can cause extensive damage, leading to a rough engine operation and compromised vehicle performance.

Fuel Cutting Out

The cam follower plays a pivotal role in the operation of fuel injectors, ensuring timely fuel delivery to the combustion chamber. A compromised cam follower can interrupt this synchrony, leading to inconsistent fuel delivery or even complete fuel cut-outs. When the fuel supply is disrupted, it can cause the engine to run lean, leading to misfires, reduced power, or even potential engine shutdown.

Engine Stalling/Not Starting

A malfunctioning cam follower can lead to significant engine problems, including stalling and difficulties in starting. These issues arise when the cam follower, integral to maintaining proper valve timing, fails to operate optimally. This affects the engine's ability to intake air and fuel efficiently, leading to imbalanced combustion.

An engine reliant on precise valve timings will struggle to sustain operations, leading to stalling or, in severe cases, preventing the engine from starting altogether.

Relevant Fault Codes

Diagnostic tools have become invaluable for pinpointing engine issues. For cam follower problems, common fault codes include:

- P0089 - Fuel Pressure Regulator 1 Performance

- P0087 - Fuel Rail/System Pressure: Too Low

- P1093 - Bank 1; Fuel Measuring System 2: Malfunction

- P2293 - Fuel Pressure Regulator Valve (N276): Mechanical Malfunction

Accurate diagnosis using these codes aids in timely interventions.

Diagnosing and Replacing a Bad Cam Follower

Diagnosis

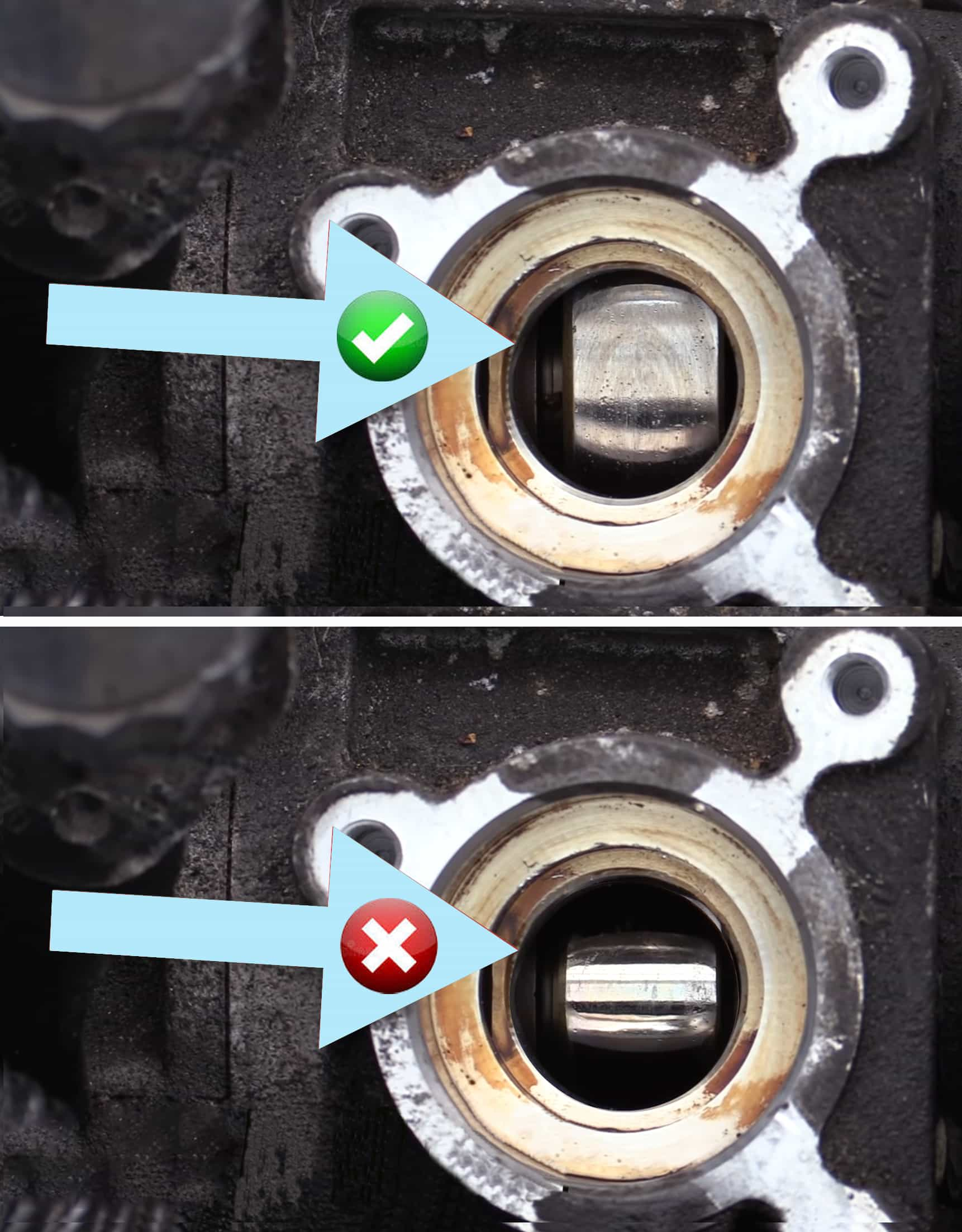

- Begin with a visual inspection. Look for signs of wear or damage on the cam follower's surface, which might indicate friction or undue pressure.

- Utilize diagnostic tools such as an engine diagnostic scanner to check for fault codes related to the cam follower or valve operation.

- Listen for unusual sounds from the engine, like clicking or tapping, which might be a direct result of cam follower degradation.

Replacement Process

Access HPFP and CAM Follower

- Detach the EA113 engine cover, which integrates the air intake.

- Unplug the MAF Sensor and release adjacent metal clips.

- Shift the engine cover sideways for complete removal.

Depressurize the Fuel System

- Unplug the fuel pump's electrical connector.

- Start the vehicle momentarily to reduce pressure.

- Disconnect the thrust sensor, remove the dust cap from the Schrader valve, and release the fuel using a 13mm valve.

Detach High-Pressure Fuel Pum

- Loosen the fuel lines at the pump base using a 17mm spanner.

- Remove the hose clamp and T30 fuel pump bolts.

- Gently ease the pump out after removing the rubber fuel line.

Change the Cam Follower

- Take out the CAM follower and inspect the CAM lobe.

- Prepare the area for the new CAM follower, ensuring it's clean and the CAM lobe is well-lubricated.

- Place the new follower, ensuring both it and the lobe are amply oiled.

Set Up the New Fuel Pump and Sensor

- Secure the pump in a vice and attach necessary parts with appropriate torque: thrust sensor (24mm spanner, 30nm), barbed fitting (17mm, 30nm), schrader valve (13mm).

- Attach the rubber fuel line, then secure the pump using new T30 bolts (10nm). Reconnect the hard metal fuel line with a 17mm spanner (27nm).

- Reconnect all electrical connectors and cap the Schrader valve.

Reassemble Air Intake and Engine Cover

- Replace the engine cover, secure the metal clips, and reconnect the MAF sensor.

- Clear any diagnostic codes and prime the fuel system before starting the engine.

For more details, please refer to the page of Cam Follower Replacement.

Tools and Parts Required for the Replacement

- Essential tools for cam follower replacement include:

- Spanners (e.g. 17mm, 13mm, 24mm)

- Ratchets (e.g. 3/8 Ratchet)

- Torque wrench (e.g. 3/8 Torque wrench)

- Capable Diagnostic Tool

- Mechanic Gloves

- Lubricants

For genuine cam follower kits, prioritize purchasing from reputable dealers or authorized distributors to guarantee part compatibility and performance.

The Importance of Proper Installation

Correct cam follower installation is vital for engine performance. When properly positioned, they maintain valve timing and reduce component wear. Incorrect installation can cause engine inefficiencies and risk damage from misaligned followers, leading to potential costly repairs.

Preventive Measures and Maintenance

The Significance of Regular Servicing

Like any mechanical component, cam followers require consistent maintenance. Regular inspections can preemptively detect and rectify potential issues, ensuring the engine's longevity.

Service Intervals for Cam Follower Replacement

It's recommended to inspect the cam follower between intervals of 10,000 – 20,000 miles. However, various factors, like driving conditions and vehicle age, can influence this schedule.

How to Maintain the Cam Follower and Extend its Lifespan

Keeping the cam follower well-lubricated and clean ensures its efficient operation. Regular check-ups and adopting preventive measures can extend the cam follower's lifespan significantly.

Conclusion

Understanding and addressing bad cam follower symptoms is vital for preserving an engine's health. Early detection, coupled with regular maintenance, ensures that the engine runs smoothly and efficiently. At Lily-Bearing, we advocate for proactive engine care and offer solutions to help you achieve just that.

Keep Learning