Cam Follower Replacement

Cam followers play a vital role in the overall health and efficiency of your engine. Neglecting the condition of this component can lead to major engine problems and costly repairs. This guide dives deep into the world of cam follower replacement, emphasizing its significance in maintaining engine health.

Understanding the Cam Follower

What is a Cam Follower and Its Function

A cam follower is essentially a specialized type of roller bearing or needle bearing. Its primary purpose is to follow cam lobe profiles in many internal combustion engines. By translating the rotational movement of the camshaft into linear motion, it plays a crucial role in actuating other engine components, such as the valves. These valves, in turn, regulate the flow of air and fuel into the combustion chamber and manage the expulsion of exhaust gases.

Benefits and Impact on Performance

The cam follower can reduce friction and supporting radial loads, ensuring the engine operates at its peak efficiency. The relationship between the cam follower's health and the engine's performance is direct and significant. A well-maintained cam follower can not only enhance your vehicle's fuel efficiency but also improve power output and extend the overall longevity of the engine. Any issues with the cam follower, such as wear and tear, can lead to suboptimal engine performance, resulting in problems like misfires, irregular idling, or unusual engine noises.

Signs of a Failing Cam Follower

Recognizing the early symptoms of a failing cam follower is crucial to avoid more severe engine complications. Common indicators include unusual engine noises, decreased fuel efficiency, reduced engine power, or even an illuminated check engine light. Furthermore, in some vehicle models, like the A4, a cam follower failure might result in substantial damage to the cam or motor.

The Importance of Timely Replacement

Delaying the replacement of a worn-out cam follower can lead to escalating engine problems. As the cam follower deteriorates, it might cause irregularities in fuel pressure, negatively impacting engine performance. Worse, a completely failed cam follower can cause significant engine damage, leading to expensive repairs or even complete engine replacement.

Diagnostic Steps

To accurately diagnose potential cam follower issues:

- Use diagnostic tools like OBD-II scanners to check for relevant error codes.

- Conduct a visual inspection for signs of wear or damage to the cam follower.

- Listen for unusual engine sounds which might indicate a failing cam follower.

Cam Follower Replacement Process

Ensuring the longevity and optimal performance of your engine requires regular maintenance and, when needed, replacement of key components. The cam follower, though small, plays a significant role in your engine's health. Here's a step-by-step guide to its replacement:

Tools and Parts Required

- New cam follower (ensure compatibility with your engine model)

- Ratchet set with relevant socket sizes

- Wrench set (especially a 17mm wrench for certain vehicles)

- Pliers

- Screwdrivers or Torx drivers (like a T15 for certain models)

- Size 6 hex bit

- Clean rags or towels

- Protective gloves and safety glasses

Step-by-Step Replacement Guide

Preparation: Before starting, ensure the engine has cooled down. Disconnect the vehicle's battery to prevent any unintentional starts.

- Locate the HPFP: The high-pressure fuel pump (HPFP) usually sits behind a shielding, often black in color, and will need to be accessed.

- Remove Shielding: Use a socket (commonly 10mm) to remove the bolts securing the shield and set it aside.

- Disconnect Fuel Lines: With pliers, carefully remove hoses connected to the HPFP. Using your wrench, detach any bolted fuel lines. Be cautious as fuel may spray out. Keep rags nearby for cleanup.

- Disconnect ignition coil harness/sensors: Utilize a T15 tool to detach the 2 bolts holding the ignition coil harness to the valve cover. Disconnect the 4 sensors linked to the ignition coil harness—2 on the top and 2 connected to the hpfp below.

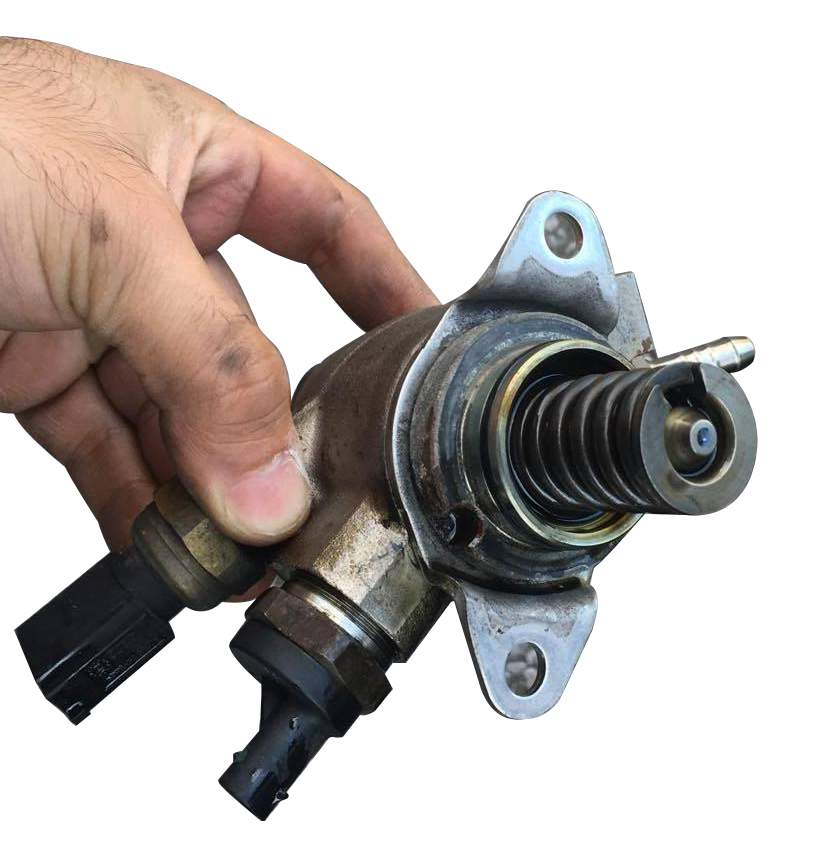

- Remove HPFP: Use the appropriate socket or hex bit to remove the bolts holding the HPFP in place. Once detached, carefully extract the HPFP, noting the position of the cam follower.

- Extract the Old Cam Follower: It should be seated between the HPFP and the camshaft. Gently remove it, noting its orientation.

- Install the New Cam Follower: Pay special attention to the cam follower's orientation. The "roller" side should be positioned inside the vacuum pump, while the HPFP spring should align with the flat section of the cam follower.

- Reassemble: Begin by placing the HPFP back in its position, ensuring it aligns correctly with the new cam follower. Reattach all bolts, hoses, and connectors that were initially disconnected. Reinstall the shielding.

- Test: Once everything is reassembled, reconnect the battery, start the vehicle, and listen for any irregular sounds. Check for fuel leaks and ensure the engine runs smoothly.

Choosing Genuine Cam Follower Kits

Always prioritize genuine cam follower kits for replacements. Authentic components guarantee longevity and optimal performance. Source your cam follower replacement components from reputable dealers, such as LILY Bearing, ensuring quality and reliability.

Preventive Maintenance

Regular inspections and preventive maintenance can prolong the life of your cam follower. By detecting and addressing issues early, you can prevent minor problems from escalating into major engine complications.

The Impact of Proper Installation

While replacing the cam follower might seem straightforward, proper installation is critical. Incorrect installation can result in inadequate fuel pressure regulation or even direct damage to the engine. Always follow the manufacturer's guidelines or consult a professional mechanic to ensure correct placement.

Conclusion

Timely cam follower replacement is integral to optimal engine performance and longevity. Utilizing quality parts, such as Stud Type Rollers and Yoke Type Rollers from LILY Bearing, ensures reliability and durability. Every vehicle owner should prioritize this crucial aspect of engine maintenance to safeguard their investment and maintain peak vehicle performance.

Keep Learning