Cancel

Bore Dia

Ring Material

For Load Direction

Outer Dia

Width

Seal Type

Balls Material

Temperature Range

Dynamic

Static

Speed (x1k rpm)

Inch Size Zirconia Ceramic Bearings

154 Products Inch Size Zirconia Ceramic Bearings

High temperature and corrosion resistance, limit temperature 400 ℃.

Inch Size Zirconia Ceramic Bearings

High temperature and corrosion resistance, limit temperature 400 ℃.

Part Number

Ring

Material

Material

For Load

Direction

Direction

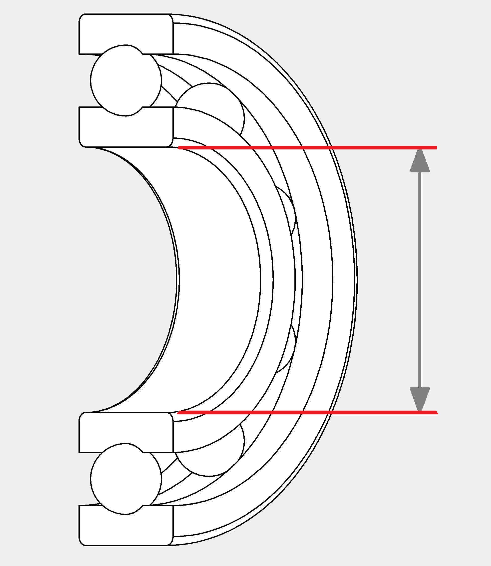

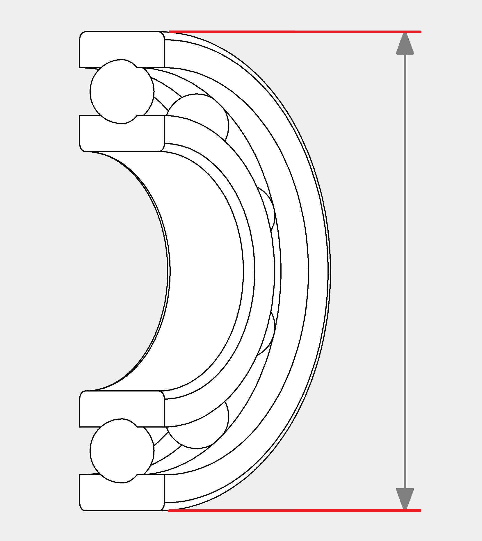

Bore Dia

Outer Dia

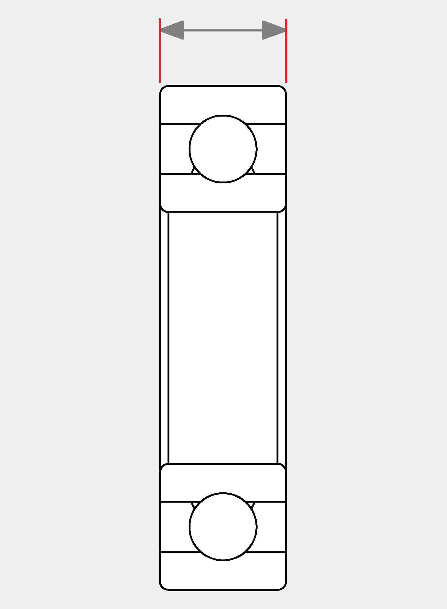

Width

Seal Type

Balls

Material

Material

Temperature

Range

Range

Dynamic

Static

Speed

(x1k rpm)

(x1k rpm)

CEZR R1-5

Zirconia

Radial

0.09375"

0.3125"

0.1094"

Open

Zro2

-176 to 752 °F

32 lbf

10 lbf

42

CEZR R1-5 2RS

Zirconia

Radial

0.09375"

0.3125"

0.1406"

Sealed

Zro2

-176 to 752 °F

32 lbf

10 lbf

42

CEZR R133

Zirconia

Radial

0.09375"

0.1875"

0.0625"

Open

Zro2

-176 to 752 °F

11 lbf

3 lbf

56

CEZR R133 2RS

Zirconia

Radial

0.09375"

0.1875"

0.0937"

Sealed

Zro2

-176 to 752 °F

8 lbf

3 lbf

56

CEZR R144

Zirconia

Radial

0.125"

0.25"

0.0937"

Open

Zro2

-176 to 752 °F

16 lbf

5 lbf

46.9

CEZR R144 2RS

Zirconia

Radial

0.125"

0.25"

0.1094"

Sealed

Zro2

-176 to 752 °F

16 lbf

5 lbf

46.9

CEZR R2

Zirconia

Radial

0.125"

0.375"

0.1562"

Open

Zro2

-176 to 752 °F

36 lbf

12 lbf

39.2

CEZR R2 2RS

Zirconia

Radial

0.125"

0.375"

0.1562"

Sealed

Zro2

-176 to 752 °F

36 lbf

12 lbf

39.2

CEZR R2-5

Zirconia

Radial

0.125"

0.3125"

0.1094"

Open

Zro2

-176 to 752 °F

32 lbf

10 lbf

42

CEZR R2-5 2RS

Zirconia

Radial

0.125"

0.3125"

0.1406"

Sealed

Zro2

-176 to 752 °F

32 lbf

10 lbf

42

CEZR R2-6

Zirconia

Radial

0.125"

0.375"

0.1094"

Open

Zro2

-176 to 752 °F

37 lbf

12 lbf

37.1

CEZR R2-6 2RS

Zirconia

Radial

0.125"

0.375"

0.1406"

Sealed

Zro2

-176 to 752 °F

37 lbf

12 lbf

37.1

CEZR R2A

Zirconia

Radial

0.125"

0.5"

0.1719"

Open

Zro2

-176 to 752 °F

37 lbf

12 lbf

37.1

CEZR R2A 2RS

Zirconia

Radial

0.125"

0.5"

0.1719"

Sealed

Zro2

-176 to 752 °F

37 lbf

12 lbf

37.1

CEZR R155

Zirconia

Radial

0.15625"

0.3125"

0.1094"

Open

Zro2

-176 to 752 °F

21 lbf

8 lbf

37.1

CEZR R155 2RS

Zirconia

Radial

0.15625"

0.3125"

0.125"

Sealed

Zro2

-176 to 752 °F

21 lbf

8 lbf

37.1

CEZR 1601

Zirconia

Radial

0.1875"

0.6875"

0.25"

Open

Zro2

-176 to 752 °F

180 lbf

66 lbf

3.5

CEZR 1601 2RS

Zirconia

Radial

0.1875"

0.6875"

0.3125"

Sealed

Zro2

-176 to 752 °F

180 lbf

66 lbf

3.5

CEZR R156

Zirconia

Radial

0.1875"

0.3125"

0.1094"

Open

Zro2

-176 to 752 °F

21 lbf

8 lbf

37.1

CEZR R156 2RS

Zirconia

Radial

0.1875"

0.3125"

0.125"

Sealed

Zro2

-176 to 752 °F

21 lbf

8 lbf

37.1

CEZR R166

Zirconia

Radial

0.1875"

0.375"

0.125"

Open

Zro2

-176 to 752 °F

41 lbf

15 lbf

35

CEZR R166 2RS

Zirconia

Radial

0.1875"

0.375"

0.125"

Sealed

Zro2

-176 to 752 °F

41 lbf

15 lbf

35

CEZR R3

Zirconia

Radial

0.1875"

0.5"

0.1562"

Open

Zro2

-176 to 752 °F

75 lbf

26 lbf

30.1

CEZR R3 2RS

Zirconia

Radial

0.1875"

0.5"

0.196"

Sealed

Zro2

-176 to 752 °F

75 lbf

26 lbf

30.1

CEZR R3A

Zirconia

Radial

0.1875"

0.625"

0.196"

Open

Zro2

-176 to 752 °F

85 lbf

34 lbf

26.6

CEZR R3A 2rs

Zirconia

Radial

0.1875"

0.625"

0.196"

Open

Zro2

-176 to 752 °F

100 lbf

39 lbf

26.6

CEZR 1602

Zirconia

Radial

0.25"

0.6875"

0.25"

Open

Zro2

-176 to 752 °F

190 lbf

72 lbf

3.5

CEZR 1602 2RS

Zirconia

Radial

0.25"

0.6875"

0.3125"

Sealed

Zro2

-176 to 752 °F

190 lbf

72 lbf

3.5

CEZR R168

Zirconia

Radial

0.25"

0.375"

0.125"

Open

Zro2

-176 to 752 °F

21 lbf

9 lbf

33.6

CEZR R168 2RS

Zirconia

Radial

0.25"

0.375"

0.125"

Sealed

Zro2

-176 to 752 °F

21 lbf

9 lbf

33.6

CEZR R188

Zirconia

Radial

0.25"

0.5"

0.125"

Open

Zro2

-176 to 752 °F

62 lbf

24 lbf

28

CEZR R188 2RS

Zirconia

Radial

0.25"

0.5"

0.1875"

Sealed

Zro2

-176 to 752 °F

62 lbf

24 lbf

28

CEZR R4

Zirconia

Radial

0.25"

0.625"

0.196"

Open

Zro2

-176 to 752 °F

85 lbf

34 lbf

26.6

CEZR R4 2RS

Zirconia

Radial

0.25"

0.625"

0.196"

Sealed

Zro2

-176 to 752 °F

85 lbf

34 lbf

26.6

CEZR R4A

Zirconia

Radial

0.25"

0.75"

0.2188"

Open

Zro2

-176 to 752 °F

134 lbf

48 lbf

25.2

CEZR R4A 2RS

Zirconia

Radial

0.25"

0.75"

0.2812"

Sealed

Zro2

-176 to 752 °F

134 lbf

48 lbf

25.2

CEZR 1603

Zirconia

Radial

0.3125"

0.875"

0.2812"

Open

Zro2

-176 to 752 °F

224 lbf

93 lbf

3.5

CEZR 1603 2RS

Zirconia

Radial

0.3125"

0.875"

0.3438"

Sealed

Zro2

-176 to 752 °F

224 lbf

93 lbf

3.5

CEZR 1605

Zirconia

Radial

0.3125"

0.9062"

0.3125"

Open

Zro2

-176 to 752 °F

224 lbf

94 lbf

3.5

CEZR 1605 2RS

Zirconia

Radial

0.3125"

0.9062"

0.3125"

Sealed

Zro2

-176 to 752 °F

224 lbf

94 lbf

3.5

CEZR R1810

Zirconia

Radial

0.3125"

0.5"

0.1562"

Open

Zro2

-176 to 752 °F

31 lbf

15 lbf

28

CEZR R1810 2RS

Zirconia

Radial

0.3125"

0.5"

0.1562"

Sealed

Zro2

-176 to 752 °F

31 lbf

15 lbf

28

CEZR 1604

Zirconia

Radial

0.375"

0.875"

0.2812"

Open

Zro2

-176 to 752 °F

225 lbf

96 lbf

3.5

CEZR 1604 2RS

Zirconia

Radial

0.375"

0.875"

0.3438"

Sealed

Zro2

-176 to 752 °F

225 lbf

96 lbf

3.5

CEZR 1606

Zirconia

Radial

0.375"

0.9062"

0.3125"

Open

Zro2

-176 to 752 °F

225 lbf

96 lbf

3.5

CEZR 1606 2RS

Zirconia

Radial

0.375"

0.9062"

0.3125"

Sealed

Zro2

-176 to 752 °F

225 lbf

96 lbf

3.5

CEZR 1614

Zirconia

Radial

0.375"

1.125"

0.375"

Open

Zro2

-176 to 752 °F

342 lbf

156 lbf

3.5

CEZR 1614 2RS

Zirconia

Radial

0.375"

1.125"

0.375"

Sealed

Zro2

-176 to 752 °F

342 lbf

156 lbf

3.5

CEZR ER1038

Zirconia

Radial

0.375"

0.625"

0.1562"

Open

Zro2

-176 to 752 °F

-

-

-

CEZR ER1038 2RS

Zirconia

Radial

0.375"

0.625"

0.1562"

Sealed

Zro2

-176 to 752 °F

-

-

-

CEZR R6

Zirconia

Radial

0.375"

0.875"

0.2188"

Open

Zro2

-176 to 752 °F

191 lbf

77 lbf

22.4

CEZR R6 2RS

Zirconia

Radial

0.375"

0.875"

0.2812"

Sealed

Zro2

-176 to 752 °F

191 lbf

77 lbf

22.4

CEZR 1607

Zirconia

Radial

0.4375"

0.9062"

0.3125"

Open

Zro2

-176 to 752 °F

304 lbf

129 lbf

3.5

CEZR 1607 2RS

Zirconia

Radial

0.4375"

0.9062"

0.3125"

Sealed

Zro2

-176 to 752 °F

304 lbf

129 lbf

3.5

CEZR 1615

Zirconia

Radial

0.4375"

1.125"

0.375"

Open

Zro2

-176 to 752 °F

344 lbf

159 lbf

3.5

CEZR 1615 2RS

Zirconia

Radial

0.4375"

1.125"

0.375"

Sealed

Zro2

-176 to 752 °F

344 lbf

159 lbf

3.5

CEZR 1620

Zirconia

Radial

0.4375"

1.375"

0.4375"

Open

Zro2

-176 to 752 °F

507 lbf

240 lbf

3.5

CEZR 1620 2RS

Zirconia

Radial

0.4375"

1.375"

0.4375"

Sealed

Zro2

-176 to 752 °F

507 lbf

240 lbf

3.5

CEZR 1616

Zirconia

Radial

0.5"

1.125"

0.375"

Open

Zro2

-176 to 752 °F

345 lbf

135 lbf

3.5

CEZR 1616 2RS

Zirconia

Radial

0.5"

1.125"

0.375"

Sealed

Zro2

-176 to 752 °F

345 lbf

135 lbf

3.5

CEZR 1621

Zirconia

Radial

0.5"

1.375"

0.4375"

Open

Zro2

-176 to 752 °F

510 lbf

244 lbf

3.5

CEZR 1621 2RS

Zirconia

Radial

0.5"

1.375"

0.4375"

Sealed

Zro2

-176 to 752 °F

510 lbf

244 lbf

3.5

CEZR ER1212

Zirconia

Radial

0.5"

0.75"

0.1562"

Open

Zro2

-176 to 752 °F

-

-

-

CEZR ER1212 2RS

Zirconia

Radial

0.5"

0.75"

0.1562"

Sealed

Zro2

-176 to 752 °F

-

-

-

CEZR R8

Zirconia

Radial

0.5"

1.125"

0.25"

Open

Zro2

-176 to 752 °F

345 lbf

153 lbf

18.9

CEZR R8 2RS

Zirconia

Radial

0.5"

1.125"

0.3125"

Sealed

Zro2

-176 to 752 °F

345 lbf

153 lbf

18.9

CEZR RLS4

Zirconia

Radial

0.5"

1.3125"

0.375"

Open

Zro2

-176 to 752 °F

491 lbf

209 lbf

22.4

CEZR RLS4 2RS

Zirconia

Radial

0.5"

1.3125"

0.375"

Sealed

Zro2

-176 to 752 °F

491 lbf

209 lbf

10.5

CEZR RMS4

Zirconia

Radial

0.5"

1.625"

0.625"

Open

Zro2

-176 to 752 °F

61 lbf

38 lbf

11.9

CEZR 1622

Zirconia

Radial

0.5625"

1.375"

0.4375"

Open

Zro2

-176 to 752 °F

513 lbf

248 lbf

3.5

CEZR 1622 2RS

Zirconia

Radial

0.5625"

1.375"

0.4375"

Sealed

Zro2

-176 to 752 °F

513 lbf

248 lbf

3.5

CEZR 1623

Zirconia

Radial

0.625"

1.375"

0.4375"

Open

Zro2

-176 to 752 °F

516 lbf

250 lbf

3.5

CEZR 1623 2RS

Zirconia

Radial

0.625"

1.375"

0.4375"

Sealed

Zro2

-176 to 752 °F

516 lbf

250 lbf

3.5

CEZR 1628

Zirconia

Radial

0.625"

1.625"

0.5"

Open

Zro2

-176 to 752 °F

630 lbf

328 lbf

3.5

CEZR 1628 2RS

Zirconia

Radial

0.625"

1.625"

0.5"

Sealed

Zro2

-176 to 752 °F

630 lbf

328 lbf

3.5

CEZR 1633

Zirconia

Radial

0.625"

1.75"

0.5"

Open

Zro2

-176 to 752 °F

630 lbf

336 lbf

3.5

CEZR 1633 2RS

Zirconia

Radial

0.625"

1.75"

0.5"

Sealed

Zro2

-176 to 752 °F

630 lbf

336 lbf

3.5

CEZR ER1458

Zirconia

Radial

0.625"

0.875"

0.1562"

Open

Zro2

-176 to 752 °F

-

-

-

CEZR ER1458 2RS

Zirconia

Radial

0.625"

0.875"

0.1562"

Sealed

Zro2

-176 to 752 °F

-

-

-

CEZR R10

Zirconia

Radial

0.625"

1.375"

0.2812"

Open

Zro2

-176 to 752 °F

476 lbf

220 lbf

14.7

CEZR R10 2RS

Zirconia

Radial

0.625"

1.375"

0.3438"

Sealed

Zro2

-176 to 752 °F

476 lbf

220 lbf

14.7

CEZR RLS5

Zirconia

Radial

0.625"

1.5625"

0.4375"

Open

Zro2

-176 to 752 °F

645 lbf

320 lbf

16.8

CEZR RLS5 2RS

Zirconia

Radial

0.625"

1.5625"

0.4375"

Sealed

Zro2

-176 to 752 °F

645 lbf

320 lbf

8.4

CEZR RMS5

Zirconia

Radial

0.625"

1.8125"

0.625"

Open

Zro2

-176 to 752 °F

910 lbf

442 lbf

15.4

CEZR 1630

Zirconia

Radial

0.75"

1.625"

0.5"

Open

Zro2

-176 to 752 °F

633 lbf

334 lbf

3.5

CEZR 1630 2RS

Zirconia

Radial

0.75"

1.625"

0.5"

Sealed

Zro2

-176 to 752 °F

633 lbf

334 lbf

3.5

CEZR 1635

Zirconia

Radial

0.75"

1.75"

0.5"

Open

Zro2

-176 to 752 °F

634 lbf

342 lbf

3.5

CEZR 1635 2RS

Zirconia

Radial

0.75"

1.75"

0.5"

Sealed

Zro2

-176 to 752 °F

634 lbf

342 lbf

3.5

CEZR 1638

Zirconia

Radial

0.75"

2"

0.5625"

Open

Zro2

-176 to 752 °F

681 lbf

387 lbf

3.5

CEZR 1638 2RS

Zirconia

Radial

0.75"

2"

0.5625"

Sealed

Zro2

-176 to 752 °F

681 lbf

387 lbf

3.5

CEZR ER1634

Zirconia

Radial

0.75"

1"

0.1562"

Open

Zro2

-176 to 752 °F

-

-

-

CEZR ER1634 2RS

Zirconia

Radial

0.75"

1"

0.1562"

Sealed

Zro2

-176 to 752 °F

-

-

-

CEZR R12

Zirconia

Radial

0.75"

1.625"

0.3125"

Open

Zro2

-176 to 752 °F

743 lbf

353 lbf

11.9

CEZR R12 2RS

Zirconia

Radial

0.75"

1.625"

0.4375"

Sealed

Zro2

-176 to 752 °F

743 lbf

353 lbf

11.9

CEZR RLS6

Zirconia

Radial

0.75"

1.875"

0.5625"

Open

Zro2

-176 to 752 °F

856 lbf

442 lbf

14

CEZR RLS6 2RS

Zirconia

Radial

0.75"

1.875"

0.5625"

Sealed

Zro2

-176 to 752 °F

856 lbf

442 lbf

7

CEZR RMS6

Zirconia

Radial

0.75"

2"

0.6875"

Open

Zro2

-176 to 752 °F

1072 lbf

526 lbf

13.3

CEZR 1640

Zirconia

Radial

0.875"

2"

0.5625"

Open

Zro2

-176 to 752 °F

680 lbf

394 lbf

3.5

CEZR 1640 2RS

Zirconia

Radial

0.875"

2"

0.5625"

Sealed

Zro2

-176 to 752 °F

680 lbf

394 lbf

3.5

CEZR R14

Zirconia

Radial

0.875"

1.875"

0.375"

Open

Zro2

-176 to 752 °F

797 lbf

392 lbf

7