Single-direction Thrust Ball Bearings Greatly Boosted Pressure Regulators

As a main bearing supplier, Lily Bearing is well-known for its high-quality bearings, professionalism as well as top-torch services. Undoubtedly, single-direction thrust ball bearings are also greatly welcomed. Not long ago, Lily Bearing successfully helped a client customize a new type of single-direction thrust ball bearings. Before this, the client had had a big headache about corrosion of bearings because those bearings with the 304 stainless steel cage, which were made by the previous bearing supplier, failed to pass the salt spray test. Therefore, the client turned to seek a proper solution from Lily Bearing.

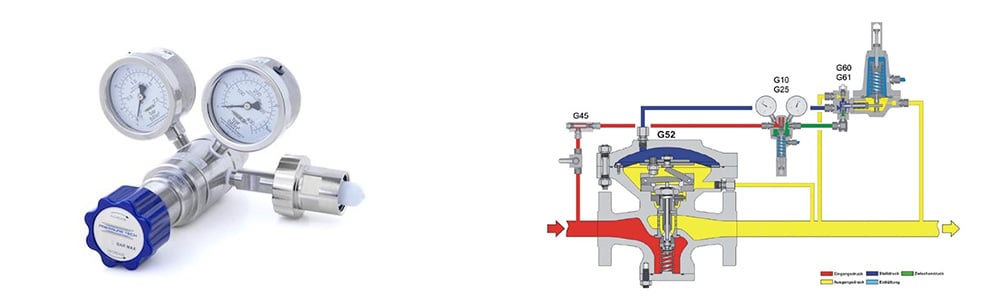

This client is a major global manufacturer of pressure regulators. It created a series of remarkable records in pressure regulators for oil and gas worldwide. Its products are mainly used in a number of key high pressure control systems such as wellhead control panels, gas analyzer systems, high pressure oxygen diving systems as well as systems for hydrogen fuel cell technology. These applications place high demands on the corrosion resistance of the bearings. The pressure regulators produced by this client have such a wide range of harsh applications, then what type of bearing can make them operate smoothly?

The experts of Lily Bearing said that single-direction thrust ball bearings were the most suitable bearings for pressure regulators. They also gave a professional in-depth explanation.

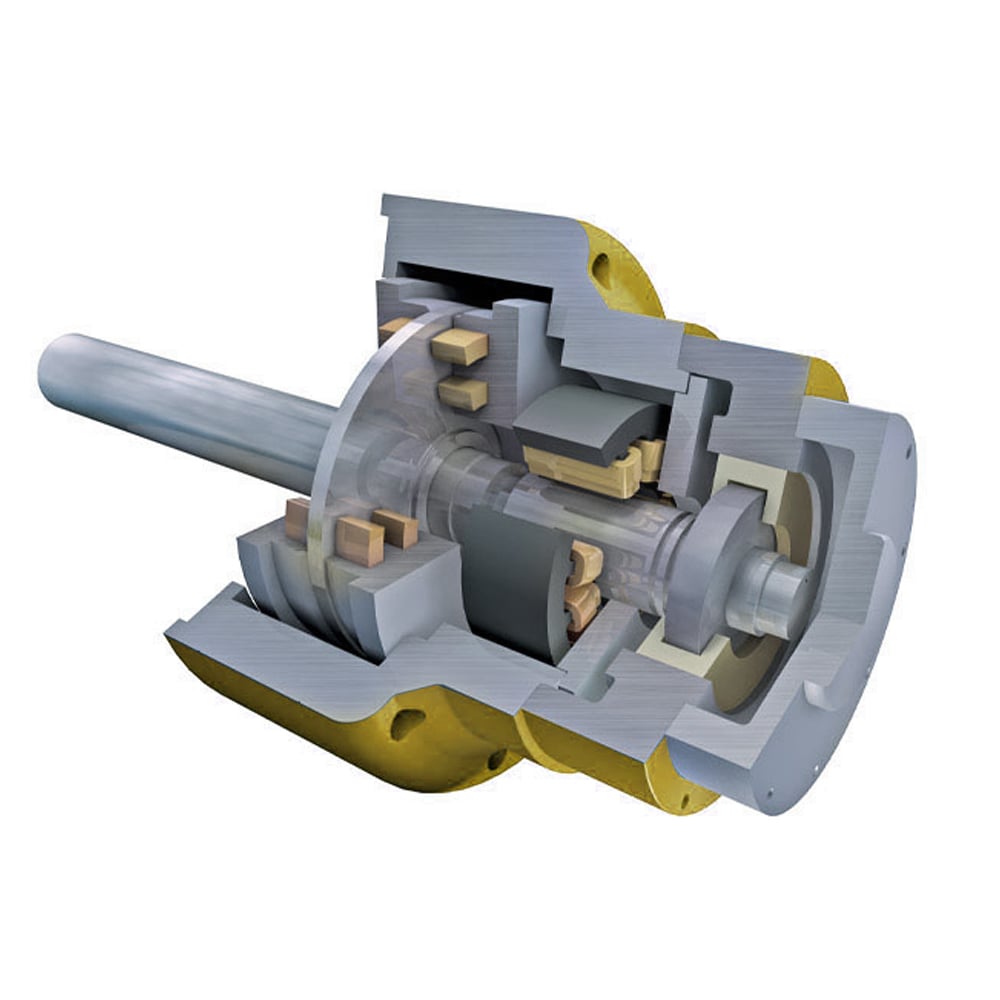

From the structures, single-direction thrust ball bearings are separated bearings, which means that the washer, the ball and the cage assembly can be mounted separately. Single-direction thrust ball bearings are indeed rolling elements which consist of a shaft ring, a housing ring as well as a ball and a cage thrust assembly. Single-direction thrust ball bearings also have an aligning seat. This equipment can make the bearings stand original misalignment. The balls in single-direction thrust ball bearings can ensure high performance at the highest speeds. Some single-direction thrust ball bearings have a flat seat ring and others have a spherical seat ring. Single-direction thrust ball bearings with spherical rings can be used in conjunction with spherical seat washers to compensate for angular alignment errors between the support surface and the shaft within the housing.

In terms of characters, single-direction thrust ball bearings produced by Lily Bearing, which adopted the ultra-precise high-speed hot heading machine forging technology, have unique flat bearing grooves. This structure can improve the bearing performance, increase the material utilization rate by nearly 20% and ensure that the bearing has low noise and a long life. In addition, the cage surfaces of single-direction thrust ball bearings are treated with a new process of hydrogen nitriding, which can make the tensile strength of the cages increase by 64%.

As far as the mechanism concerned, single-direction thrust ball bearings are mainly subjected to axial load in a pressure regulator. The axial load is positively related to the size of the thrust. The greater the thrust, the greater the axial load. And vice versa.

In response to the client's needs for salt spray environment, the team of Lily's engineers initially gave two kinds of solutions, that is, the solution of stainless steel thrust ball bearings and the solution of full ceramic single-direction thrust ball bearings. However, due to the client's consideration about the price, the team of engineers helped exclude the all-ceramic bearing solution. They used single-direction thrust ball bearings with 440 stainless steel upper and lower spacers, the PEEK cage and zirconia ceramic balls in a creative way. This solution eventually passed the salt spray test. As a matter of fact, these single direction thrust bearings with zirconia ceramic balls are also corrosion resistant bearings, which can help pressure regulators deal with the challenges of humidity or other chemical environments.

In the email, the client mentioned, "... since using your single-direction thrust ball bearings with zirconia ceramic balls, our pressure regulators have been working well. One of our clients used the pressure regulator in marine applications with depth of up to 3000 meters and it is still sensitive and ideal for underwater control applications.

In the process of installation of single-direction thrust ball bearings, the client also encountered some confusion. Experts of Lily Bearing gave corresponding suggestions. First of all, identify the bearing's tight ring and the loose ring according to the bearing's inner diameter size or bore size; Secondly, determine the stationary parts of the pressure regulator; Then, no matter what the situation is, the bearing's loose rings should always lean on the end face of the stationary parts. In addition, experts also pointed out that the installation of single-direction thrust ball bearings is simple, but during the actual maintenance, the chances of error are not small. The main error point is that the tight ring and the loose ring of a bearing are installed in a wrong way, which can make the journal worn and then lead to bearing failure. When the shaft rotates, the tight ring is driven, and friction occurs with the end face of the stationary parts. In the axial force, the frictional moment will be larger than the resistance moment of the inner diameter, resulting in forced rotation of the tight ring and the shaft mating surface, intensifying the journal wear.

In addition to single-direction thrust ball bearings, Lily bearing has other different series of standardized bearings. If clients have a stringent application environment, Lily’s experts will help them customize the best bearing solution according to their actual needs and working conditions.

CATEGORIES

- Miniature Bearings(2)

- Thin Section Bearings(1)

- Ceramic Bearings(7)

- Stainless Steel Bearings(3)

- Needle Roller Bearings(3)

- Spherical Roller Bearings(1)

- Thrust Ball Bearings(2)

- Roller Bearings(1)

- Tapered Roller Bearings(2)

- Slewing Ring Bearings(2)

- Angular Contact Ball Bearings(1)

- Sleeve Bearings(1)

- Others(44)

- Low Temperature Bearings(1)

- Ball Bearings(9)

- Bearing Load(4)

- Bearing Components(1)

- Types of Bearings(4)

- Thrust Bearings(1)

- Bearing Technical Knowledge(21)

- Aerospace Bearings(2)

- Polyurethane Rollers(2)

- Cam Follower(3)

- Linear Bearings(1)

- Spherical Bearings(1)

LATEST ARTICLES

-

Bearing Maintenance 101: A Guide to Extending the Life of Your Bearings

Bearing Maintenance 101: A Guide to Extending the Life of Your Bearings -

The Impact of Counterfeit Bearings On the Industry and How to Avoid Them

The Impact of Counterfeit Bearings On the Industry and How to Avoid Them -

Chrome Steel vs. Stainless Steel Bearings: Which Do You Need?

Chrome Steel vs. Stainless Steel Bearings: Which Do You Need? -

Magnetic Bearings: What They Are & How They Work

Magnetic Bearings: What They Are & How They Work -

Expert Tips On Installing & Removing Bearings for Industry Professionals

Expert Tips On Installing & Removing Bearings for Industry Professionals -

How Much Grease to Put in Bearings: A Comprehensive Guide

How Much Grease to Put in Bearings: A Comprehensive Guide