Cancel

System of Measurement

Bore Dia

Ring Material

For Load Direction

Outer Dia

Width

Seal Type

Contact Angle

Cage Material

Ball Material

Series

Thin Section Bearings Type

Dynamic

Static

- Equivalent to Manufacturer :

- KAYDON

Constant Section (CS) Bearings

1723 Productsbearings.png?format=webp) Constant Section (CS) Bearings

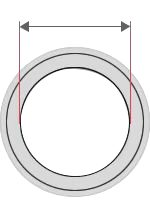

Constant Section (CS) Bearings: These thin section bearings have an extremely small, predominantly square cross-section. the cross-section remains constant giving them the unique description as a constant section bearings.

Constant Section (CS) Bearings

Constant Section (CS) Bearings: These thin section bearings have an extremely small, predominantly square cross-section. the cross-section remains constant giving them the unique description as a constant section bearings.

Part Number

Ring

Material

Material

For Load

Direction

Direction

Bore Dia

Outer Dia

Width

Seal Type

Ball

Material

Material

Contact

Angle

Angle

Series

Dynamic

Static

Price

SAA10AG0

440C Stainless Steel

Angular Contact

1"

1.375"

0.1875"

Open

440C Stainless Steel

30°

SAA 3/16" x 3/16"

194 lbf

340 lbf

$ 107.97

SAA10CL0

440C Stainless Steel

Radial

1"

1.375"

0.1875"

Open

440C Stainless Steel

-

SAA 3/16" x 3/16"

188 lbf

290 lbf

$ 58.79

SAA10XL0

440C Stainless Steel

Four Point Contact

1"

1.375"

0.1875"

Open

440C Stainless Steel

-

SAA 3/16" x 3/16"

247 lbf

290 lbf

$ 100.83

JHA10CL0

Chrome Steel

Radial

1"

1.375"

0.25"

Sealed

Chrome Steel

-

JHA 3/16" x 1/4"

188 lbf

290 lbf

$ 37.64

JHA10XL0

Chrome Steel

Four Point Contact

1"

1.375"

0.25"

Sealed

Chrome Steel

-

JHA 3/16" x 1/4"

247 lbf

290 lbf

$ 40.31

KAA-10 CL0

Chrome Steel

Radial

1"

1.375"

0.1875"

Open

Chrome Steel

-

KAA 3/16" x 3/16"

188 lbf

290 lbf

$ 29.63

KAA10AG0

Chrome Steel

Angular Contact

1"

1.375"

0.1875"

Open

Chrome Steel

30°

KAA 3/16" x 3/16"

194 lbf

340 lbf

$ 37.05

KAA10AG6

Chrome Steel

Angular Contact

1"

1.375"

0.1875"

Open

Chrome Steel

30°

KAA 3/16" x 3/16"

194 lbf

340 lbf

$ 37.05

KAA10CL0

Chrome Steel

Radial

1"

1.375"

0.1875"

Open

Chrome Steel

-

KAA 3/16" x 3/16"

188 lbf

290 lbf

$ 29.63

KAA10XL0

Chrome Steel

Four Point Contact

1"

1.375"

0.1875"

Open

Chrome Steel

-

KAA 3/16" x 3/16"

247 lbf

290 lbf

$ 31.08

KAA10XL0K

Chrome Steel

Four Point Contact

1"

1.375"

0.1875"

Open

Chrome Steel

-

KAA 3/16" x 3/16"

247 lbf

290 lbf

$ 31.08

NAA10AG0

Chrome Steel

Angular Contact

1"

1.375"

0.1875"

Open

Chrome Steel

30°

NAA 3/16" x 3/16"

194 lbf

340 lbf

$ 55.57

NAA10CL0

Chrome Steel

Radial

1"

1.375"

0.1875"

Open

Chrome Steel

-

NAA 3/16" x 3/16"

188 lbf

290 lbf

$ 37.03

NAA10XL0

Chrome Steel

Four Point Contact

1"

1.375"

0.1875"

Open

Chrome Steel

-

NAA 3/16" x 3/16"

247 lbf

290 lbf

$ 44.02

SAA15AG0

440C Stainless Steel

Angular Contact

1.5"

1.875"

0.1875"

Open

440C Stainless Steel

30°

SAA 3/16" x 3/16"

238 lbf

480 lbf

$ 119.63

SAA15CL0

440C Stainless Steel

Radial

1.5"

1.875"

0.1875"

Open

440C Stainless Steel

-

SAA 3/16" x 3/16"

225 lbf

400 lbf

$ 69.14

SAA15XL0

440C Stainless Steel

Four Point Contact

1.5"

1.875"

0.1875"

Open

440C Stainless Steel

-

SAA 3/16" x 3/16"

296 lbf

400 lbf

$ 108.29

JHA15CL0

Chrome Steel

Radial

1.5"

1.875"

0.25"

Sealed

Chrome Steel

-

JHA 3/16" x 1/4"

225 lbf

400 lbf

$ 35.89

JHA15XL0

Chrome Steel

Four Point Contact

1.5"

1.875"

0.25"

Sealed

Chrome Steel

-

JHA 3/16" x 1/4"

296 lbf

400 lbf

$ 52.41

KAA15AG0

Chrome Steel

Angular Contact

1.5"

1.875"

0.1875"

Open

Chrome Steel

30°

KAA 3/16" x 3/16"

238 lbf

480 lbf

$ 65.94

KAA15AG6

Chrome Steel

Angular Contact

1.5"

1.875"

0.1875"

Open

Chrome Steel

30°

KAA 3/16" x 3/16"

238 lbf

480 lbf

$ 65.94

KAA15CL0

Chrome Steel

Radial

1.5"

1.875"

0.1875"

Open

Chrome Steel

-

KAA 3/16" x 3/16"

225 lbf

400 lbf

$ 32.05

KAA15XL0

Chrome Steel

Four Point Contact

1.5"

1.875"

0.1875"

Open

Chrome Steel

-

KAA 3/16" x 3/16"

296 lbf

400 lbf

$ 62.83

NAA15AG0

Chrome Steel

Angular Contact

1.5"

1.875"

0.1875"

Open

Chrome Steel

30°

NAA 3/16" x 3/16"

238 lbf

480 lbf

$ 60.43

NAA15CL0

Chrome Steel

Radial

1.5"

1.875"

0.1875"

Open

Chrome Steel

-

NAA 3/16" x 3/16"

225 lbf

400 lbf

$ 40.07

NAA15XL0

Chrome Steel

Four Point Contact

1.5"

1.875"

0.1875"

Open

Chrome Steel

-

NAA 3/16" x 3/16"

296 lbf

400 lbf

$ 48.79

SAA17AG0

440C Stainless Steel

Angular Contact

1.75"

2.125"

0.1875"

Open

440C Stainless Steel

30°

SAA 3/16" x 3/16"

251 lbf

530 lbf

$ 138.46

SAA17CL0

440C Stainless Steel

Radial

1.75"

2.125"

0.1875"

Open

440C Stainless Steel

-

SAA 3/16" x 3/16"

242 lbf

460 lbf

$ 87.63

SAA17XL0

440C Stainless Steel

Four Point Contact

1.75"

2.125"

0.1875"

Open

440C Stainless Steel

-

SAA 3/16" x 3/16"

319 lbf

460 lbf

$ 127.68

JHA17CL0

Chrome Steel

Radial

1.75"

2.125"

0.25"

Sealed

Chrome Steel

-

JHA 3/16" x 1/4"

242 lbf

460 lbf

$ 47.59

JHA17XL0

Chrome Steel

Four Point Contact

1.75"

2.125"

0.25"

Sealed

Chrome Steel

-

JHA 3/16" x 1/4"

319 lbf

460 lbf

$ 47.84

KAA17AG0

Chrome Steel

Angular Contact

1.75"

2.125"

0.1875"

Open

Chrome Steel

30°

KAA 3/16" x 3/16"

251 lbf

530 lbf

$ 41.77

KAA17CL0

Chrome Steel

Radial

1.75"

2.125"

0.1875"

Open

Chrome Steel

-

KAA 3/16" x 3/16"

242 lbf

460 lbf

$ 37.15

KAA17XL0

Chrome Steel

Four Point Contact

1.75"

2.125"

0.1875"

Open

Chrome Steel

-

KAA 3/16" x 3/16"

319 lbf

460 lbf

$ 37.64

NAA17AG0

Chrome Steel

Angular Contact

1.75"

2.125"

0.1875"

Open

Chrome Steel

30°

NAA 3/16" x 3/16"

251 lbf

530 lbf

$ 62.55

NAA17CL0

Chrome Steel

Radial

1.75"

2.125"

0.1875"

Open

Chrome Steel

-

NAA 3/16" x 3/16"

242 lbf

460 lbf

$ 46.44

NAA17XL0

Chrome Steel

Four Point Contact

1.75"

2.125"

0.1875"

Open

Chrome Steel

-

NAA 3/16" x 3/16"

319 lbf

460 lbf

$ 49.63

SA020AR0

440C Stainless Steel

Angular Contact

2"

2.5"

0.25"

Open

440C Stainless Steel

30°

SA 1/4" x 1/4"

405 lbf

790 lbf

$ 103.47

SA020CP0

440C Stainless Steel

Radial

2"

2.5"

0.25"

Open

440C Stainless Steel

-

SA 1/4" x 1/4"

393 lbf

680 lbf

$ 83.16

SA020XP0

440C Stainless Steel

Four Point Contact

2"

2.5"

0.25"

Open

440C Stainless Steel

-

SA 1/4" x 1/4"

514 lbf

680 lbf

$ 94.97

SB020AR0

440C Stainless Steel

Angular Contact

2"

2.625"

0.3125"

Open

440C Stainless Steel

30°

SB 5/16" x 5/16"

601 lbf

1090 lbf

$ 111.45

SB020CP0

440C Stainless Steel

Radial

2"

2.625"

0.3125"

Open

440C Stainless Steel

-

SB 5/16" x 5/16"

577 lbf

930 lbf

$ 97.37

SB020XP0

440C Stainless Steel

Four Point Contact

2"

2.625"

0.3125"

Open

440C Stainless Steel

-

SB 5/16" x 5/16"

758 lbf

930 lbf

$ 100.92

JA020CP0

Chrome Steel

Radial

2"

2.5"

0.25"

Sealed

Chrome Steel

-

JA 1/4" x 1/4"

393 lbf

680 lbf

$ 47.35

JA020XP0

Chrome Steel

Four Point Contact

2"

2.5"

0.25"

Sealed

Chrome Steel

-

JA 1/4" x 1/4"

514 lbf

680 lbf

$ 53.51

JB020CP0

Chrome Steel

Radial

2"

2.625"

0.3125"

Sealed

Chrome Steel

-

JB 5/16" x 5/16"

577 lbf

930 lbf

$ 54.39

JB020XP0

Chrome Steel

Four Point Contact

2"

2.625"

0.3125"

Sealed

Chrome Steel

-

JB 5/16" x 5/16"

758 lbf

930 lbf

$ 56.34

KA020AR0

Chrome Steel

Angular Contact

2"

2.5"

0.25"

Open

Chrome Steel

30°

KA 1/4" x 1/4"

450 lbf

790 lbf

$ 47.84

KA020BR0K

Chrome Steel

Angular Contact

2"

2.5"

0.25"

Open

Chrome Steel

30°

KA 1/4" x 1/4"

450 lbf

790 lbf

$ 47.84

KA020CP0

Chrome Steel

Radial

2"

2.5"

0.25"

Open

Chrome Steel

-

KA 1/4" x 1/4"

393 lbf

680 lbf

$ 38.12

KA020CP6

Chrome Steel

Radial

2"

2.5"

0.25"

Open

Chrome Steel

-

KA 1/4" x 1/4"

393 lbf

680 lbf

$ 38.12

KA020XP0

Chrome Steel

Four Point Contact

2"

2.5"

0.25"

Open

Chrome Steel

-

KA 1/4" x 1/4"

514 lbf

680 lbf

$ 39.34

KA020XP4K

Chrome Steel

Four Point Contact

2"

2.5"

0.25"

Open

Chrome Steel

-

KA 1/4" x 1/4"

514 lbf

680 lbf

$ 39.34

KB020AR0

Chrome Steel

Angular Contact

2"

2.625"

0.3125"

Open

Chrome Steel

30°

KB 5/16" x 5/16"

601 lbf

1090 lbf

$ 54.39

KB020CP0

Chrome Steel

Radial

2"

2.625"

0.3125"

Open

Chrome Steel

-

KB 5/16" x 5/16"

577 lbf

930 lbf

$ 49.40

KB020XP0

Chrome Steel

Four Point Contact

2"

2.625"

0.3125"

Open

Chrome Steel

-

KB 5/16" x 5/16"

758 lbf

930 lbf

$ 51.14

KB020XP6K

Chrome Steel

Four Point Contact

2"

2.625"

0.3125"

Open

Chrome Steel

-

KB 5/16" x 5/16"

758 lbf

930 lbf

$ 51.14

NA020AR0

Chrome Steel

Angular Contact

2"

2.5"

0.25"

Open

Chrome Steel

30°

NA 1/4" x 1/4"

405 lbf

790 lbf

$ 59.80

NA020CP0

Chrome Steel

Radial

2"

2.5"

0.25"

Open

Chrome Steel

-

NA 1/4" x 1/4"

393 lbf

680 lbf

$ 47.65

NA020XP0

Chrome Steel

Four Point Contact

2"

2.5"

0.25"

Open

Chrome Steel

-

NA 1/4" x 1/4"

514 lbf

680 lbf

$ 53.37

NB020AR0

Chrome Steel

Angular Contact

2"

2.625"

0.3125"

Open

Chrome Steel

30°

NB 5/16" x 5/16"

601 lbf

1090 lbf

$ 67.99

NB020CP0

Chrome Steel

Radial

2"

2.625"

0.3125"

Open

Chrome Steel

-

NB 5/16" x 5/16"

577 lbf

930 lbf

$ 61.75

NB020XP0

Chrome Steel

Four Point Contact

2"

2.625"

0.3125"

Open

Chrome Steel

-

NB 5/16" x 5/16"

758 lbf

930 lbf

$ 63.92

WA020CP0

440C Stainless Steel

Radial

2"

2.5"

0.25"

Sealed

440C Stainless Steel

-

WA 1/4" x 1/4"

393 lbf

680 lbf

$ 189.40

WA020XP0

440C Stainless Steel

Four Point Contact

2"

2.5"

0.25"

Sealed

440C Stainless Steel

-

WA 1/4" x 1/4"

514 lbf

680 lbf

$ 214.04

WB020CP0

440C Stainless Steel

Radial

2"

2.625"

0.3125"

Sealed

440C Stainless Steel

-

JB 5/16" x 5/16"

577 lbf

930 lbf

$ 54.39

WB020XP0

440C Stainless Steel

Four Point Contact

2"

2.625"

0.3125"

Sealed

440C Stainless Steel

-

JB 5/16" x 5/16"

758 lbf

930 lbf

$ 56.34

SA025AR0

440C Stainless Steel

Angular Contact

2.5"

3"

0.25"

Open

440C Stainless Steel

30°

SA 1/4" x 1/4"

459 lbf

960 lbf

$ 113.64

SA025CP0

440C Stainless Steel

Radial

2.5"

3"

0.25"

Open

440C Stainless Steel

-

SA 1/4" x 1/4"

442 lbf

830 lbf

$ 88.24

SA025XP0

440C Stainless Steel

Four Point Contact

2.5"

3"

0.25"

Open

440C Stainless Steel

-

SA 1/4" x 1/4"

583 lbf

830 lbf

$ 230.00

SB025AR0

440C Stainless Steel

Angular Contact

2.5"

3.125"

0.3125"

Open

440C Stainless Steel

30°

SB 5/16" x 5/16"

675 lbf

1340 lbf

$ 120.70

SB025CP0

440C Stainless Steel

Radial

2.5"

3.125"

0.3125"

Open

440C Stainless Steel

-

SB 5/16" x 5/16"

644 lbf

1140 lbf

$ 97.62

SB025XP0

440C Stainless Steel

Four Point Contact

2.5"

3.125"

0.3125"

Open

440C Stainless Steel

-

SB 5/16" x 5/16"

848 lbf

1140 lbf

$ 103.45

JA025CP0

Chrome Steel

Radial

2.5"

3"

0.25"

Sealed

Chrome Steel

-

JA 1/4" x 1/4"

442 lbf

830 lbf

$ 71.50

JA025XP0

Chrome Steel

Four Point Contact

2.5"

3"

0.25"

Sealed

Chrome Steel

-

JA 1/4" x 1/4"

583 lbf

830 lbf

$ 56.25

JB025CP0

Chrome Steel

Radial

2.5"

3.125"

0.3125"

Sealed

Chrome Steel

-

JB 5/16" x 5/16"

644 lbf

1140 lbf

$ 120.00

JB025XP0

Chrome Steel

Four Point Contact

2.5"

3.125"

0.3125"

Sealed

Chrome Steel

-

JB 5/16" x 5/16"

848 lbf

1140 lbf

$ 57.55

KA025AR0

Chrome Steel

Angular Contact

2.5"

3"

0.25"

Open

Chrome Steel

30°

KA 1/4" x 1/4"

459 lbf

960 lbf

$ 51.48

KA025CP0

Chrome Steel

Radial

2.5"

3"

0.25"

Open

Chrome Steel

-

KA 1/4" x 1/4"

442 lbf

830 lbf

$ 40.31

KA025XP0

Chrome Steel

Four Point Contact

2.5"

3"

0.25"

Open

Chrome Steel

-

KA 1/4" x 1/4"

583 lbf

830 lbf

$ 41.52

KB025AR0

Chrome Steel

Angular Contact

2.5"

3.125"

0.3125"

Open

Chrome Steel

30°

KB 5/16" x 5/16"

675 lbf

1340 lbf

$ 60.05

KB025CP0

Chrome Steel

Radial

2.5"

3.125"

0.3125"

Open

Chrome Steel

-

KB 5/16" x 5/16"

644 lbf

1140 lbf

$ 52.93

KB025XP0

Chrome Steel

Four Point Contact

2.5"

3.125"

0.3125"

Open

Chrome Steel

-

KB 5/16" x 5/16"

848 lbf

1140 lbf

$ 54.91

KB025XP0L

Chrome Steel

Four Point Contact

2.5"

3.125"

0.3125"

Open

Chrome Steel

-

KB 5/16" x 5/16"

848 lbf

1140 lbf

$ 54.91

NA025AR0

Chrome Steel

Angular Contact

2.5"

3"

0.25"

Open

Chrome Steel

30°

NA 1/4" x 1/4"

459 lbf

960 lbf

$ 64.35

NA025CP0

Chrome Steel

Radial

2.5"

3"

0.25"

Open

Chrome Steel

-

NA 1/4" x 1/4"

442 lbf

830 lbf

$ 50.39

NA025XP0

Chrome Steel

Four Point Contact

2.5"

3"

0.25"

Open

Chrome Steel

-

NA 1/4" x 1/4"

583 lbf

830 lbf

$ 56.43

NB025AR0

Chrome Steel

Angular Contact

2.5"

3.125"

0.3125"

Open

Chrome Steel

30°

NB 5/16" x 5/16"

675 lbf

1340 lbf

$ 76.35

NB025CP0

Chrome Steel

Radial

2.5"

3.125"

0.3125"

Open

Chrome Steel

-

NB 5/16" x 5/16"

644 lbf

1140 lbf

$ 66.16

NB025XP0

Chrome Steel

Four Point Contact

2.5"

3.125"

0.3125"

Open

Chrome Steel

-

NB 5/16" x 5/16"

848 lbf

1140 lbf

$ 68.63

WA025CP0

440C Stainless Steel

Radial

2.5"

3"

0.25"

Sealed

440C Stainless Steel

-

WA 1/4" x 1/4"

442 lbf

830 lbf

$ 286.00

WA025XP0

440C Stainless Steel

Four Point Contact

2.5"

3"

0.25"

Sealed

440C Stainless Steel

-

WA 1/4" x 1/4"

583 lbf

830 lbf

$ 225.00

WB025CP0

440C Stainless Steel

Radial

2.5"

3.125"

0.3125"

Sealed

440C Stainless Steel

-

JB 5/16" x 5/16"

644 lbf

1140 lbf

$ 120.00

SA027XP0

440C Stainless Steel

Four Point Contact

2.75"

3.25"

0.25"

Open

440C Stainless Steel

-

SA 1/4" x 1/4"

614 lbf

910 lbf

$ 106.49

KA027XP0

Chrome Steel

Four Point Contact

2.75"

3.25"

0.25"

Open

Chrome Steel

-

KA 1/4" x 1/4"

614 lbf

910 lbf

$ 42.88

SA030AR0

440C Stainless Steel

Angular Contact

3"

3.5"

0.25"

Open

440C Stainless Steel

30°

SA 1/4" x 1/4"

507 lbf

1140 lbf

$ 116.67

SA030CP0

440C Stainless Steel

Radial

3"

3.5"

0.25"

Open

440C Stainless Steel

-

SA 1/4" x 1/4"

487 lbf

990 lbf

$ 93.25

SA030XP0

440C Stainless Steel

Four Point Contact

3"

3.5"

0.25"

Open

440C Stainless Steel

-

SA 1/4" x 1/4"

643 lbf

990 lbf

$ 265.00

SB030AR0

440C Stainless Steel

Angular Contact

3"

3.625"

0.3125"

Open

440C Stainless Steel

30°

SB 5/16" x 5/16"

734 lbf

1550 lbf

$ 150.11

SB030CP0

440C Stainless Steel

Radial

3"

3.625"

0.3125"

Open

440C Stainless Steel

-

SB 5/16" x 5/16"

707 lbf

1340 lbf

$ 108.53