Cancel

Spindle Bearings

Spindle bearings are very accurately engineered components and as such are very important to the successful performance of the machine tool. With high running accuracy, high-speed performance and high system rigidity, LILY super-precision spindle bearings are ideal for machine tools spindle units. The bearings are designed also to minimize noise, vibration and heat generation.

- Types:High-speed, super precision, universal angular contact, ball screw support

- Configurations:duplex, triplex, quad sets, ball-ball, ball-roller

- Materials:52100 steel, custom high-carbon steels, hybrid, ceramic.

- Precision:Up to ABEC9/RBEC9

Handle Machine Tool Spindle Bearings

- Keep your workspace tidy and clean.

- Avoid damage by reducing movement during transport.

- Leave spindle ball bearings in airtight packaging until you begin with their installation.

- Apply axial load only along the marked lines on the outer ring.

- Avoid transmitting assembly forces through the balls.

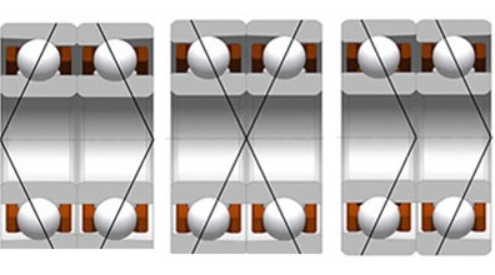

- Assemble pair bearings of type DB, DF, and DT only with the intended components in the right order. (Universally matched bearings require no particular order.)

- Let spindle ball bearings run in at high rotational speed before putting them into operation.

Seal Types

Open

Sealed

Ball Material

Chrome Steel

Ceramic

Matched Arrangement

Bore Dia

Outer Dia

Width

Spindle Ball Bearings - Designation Example

71922 CDGBTNHA/PA9AL

-

719In accordance with ISO dimension series 19

-

22(x5) 110 mm bore diameter

-

CD15° contact angle, high-capacity design

-

GBSingle, universally matchable, moderate preload

-

TNHAGlass fibre reinforced PEEK, outer ring centred

-

PA9ADimensional and geometrical tolerances in accordance with ISO tolerance class 2

-

LAnnular groove with two lubrication holes on the non-thrust side of the outer ring

-

EQand two annular grooves fitted with O-rings in the outer ring