What Does a Bad Bearing Sound Like?

Bearings are crucial components in machinery and vehicles, ensuring smooth operation and reducing friction between moving parts. Yet, when they deteriorate, they speak up. In this exploration, we listen to those sounds, with a spotlight on miniature bearings, the miniature marvels in the world of mechanics.

Understanding Bearings

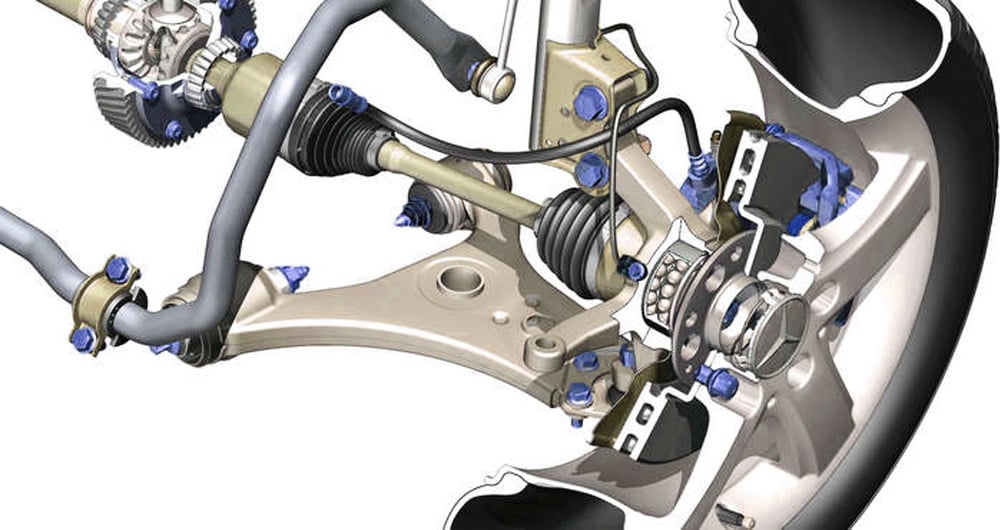

Bearings are mechanical elements that allow parts to move smoothly, supporting radial and axial loads. They are integral in everything from household appliances to industrial machinery and vehicles. Common types of bearings include ball bearings, roller bearings, and needle bearings, each with distinct uses and characteristics.

For miniature bearings, they include:

How Can You Tell if a Bearing Is Bad?

The quality of bearings, regardless of their size, can be assessed using the following methods.

Using Diagnostic Tools

Employ specialized tools like mechanical stethoscopes to pinpoint noise sources and vibration analysis tools for detecting irregularities in bearing operation.

Visual and Physical Inspection

Conduct thorough visual checks for signs of wear, corrosion, or damage, and assess the bearing's physical condition through tactile tests like checking for play or roughness.

Understanding the Risks

Recognize that neglecting bearing issues can lead to machinery failure, safety hazards, and increased repair costs, emphasizing the importance of timely diagnosis and intervention.

What Does A Bad Bearing Sound Like?

Detecting the early signs of bearing failure is critical for maintaining the efficiency and safety of machinery and vehicles. There are several sound indicators that can alert you to potential bearing issues.

The Sounds of Bad Wheel Bearings

- Snapping or Clicking Noise: This noise typically arises from excessive bearing endplay and is most noticeable during cornering or sharp turns at moderate speeds. It's important to differentiate this from similar noises that might originate from a damaged CV joint.

- Knocking or Thumping Noise: A knocking sound often indicates a wheel bearing that isn't rotating smoothly, possibly due to wear or damage, hindering its free movement.

- Grinding or Humming Noise: A persistent humming or grinding noise might point towards a compromised wheel bearing or a worn tire. The noise exacerbates into a more distinct growling sound as vehicle speed increases, strongly suggesting a wheel bearing issue.

The Sounds of Bad Miniature Bearings

For new miniature bearings, noise analysis machines can be used to identify potential issues.

- High-Pitched Squealing or Whining: This noise often indicates a lack of lubrication or the onset of corrosion.

- Grinding or Scraping: These sounds suggest that the bearing has suffered significant wear, potentially due to debris contamination or overloading.

- Rattling or Clicking: Such noises can point to loose or damaged parts within the bearing assembly.

When small bearings are already assembled into a product, significant damage can be roughly detected by ear. However, this method is less precise and may not identify minor damages.

For a more accurate assessment of assembled micro bearings, spectrum analysis can be employed, offering a finer level of detail in detecting anomalies.

In cases where small bearings have been disassembled and show signs of disassembly scars, auditory analysis is not effective. Instead, a detailed examination using microscopes and impurity filtering is necessary to pinpoint the cause of damage.

Why Do Bad Bearings Make Strange Noises?

Understanding bearing damage causes is crucial for implementing maintenance strategies and operational practices that prolong bearing life and ensure machinery reliability.

Mechanical Stress and Overloading

Bearings are designed to withstand specific load limits. Exceeding these limits, either through overloading or shock loads, accelerates wear and tear, significantly reducing their lifespan.

Improper Installation and Misalignment

Incorrect installation or misalignment of bearings can cause uneven distribution of load. This imbalance leads to excessive stress on certain parts of the bearing, hastening its deterioration.

Inadequate Lubrication

Lubrication minimizes friction and wear in bearings. Insufficient or inappropriate lubrication increases the risk of overheating and wear, shortening the bearing's operational life.

Contamination

Exposure to contaminants like dust, dirt, and moisture can severely affect bearings. These particles can infiltrate the bearings, causing abrasion and corrosion, thereby compromising their functionality and durability.

Extreme Temperatures

Bearings operating in environments with excessively high or low temperatures can experience material fatigue or loss of lubrication effectiveness, leading to faster degradation.

Vibration During Inactivity

Bearings subjected to vibration while not in operation, such as those in machinery that is idle for extended periods, can develop indentations in the raceways, leading to premature failure when the machinery is restarted.

Implications of Ignoring Bad Bearings

Disregarding abnormal sounds in bearings of any kind can result in multiple problems, such as:

- Machinery Failure: Causes breakdowns and operational downtime.

- Safety Risks: Endangers operators and can lead to accidents.

- Higher Costs: Leads to expensive repairs or replacements.

- Reduced Efficiency: Decreases machinery performance and increases energy use.

- Extra Wear: Accelerates wear on other machine parts.

Preventive Measures and Maintenance Tips

To maintain bearings effectively, regularly inspect for wear, ensure adequate lubrication, and follow manufacturer guidelines. Prevent premature wear by avoiding overloading, ensuring alignment, and protecting bearings from contaminants and extreme conditions.

Conclusion

The subtle, often overlooked sounds of bearings can herald significant issues within machinery. Recognizing these sounds, especially from micro bearings, is crucial in maintaining efficiency and safety. LILY Bearing's extensive selection ensures that, no matter the application, your machinery can continue to perform its mechanical melody flawlessly.

Keep Learning