Silicon Nitride Balls: Revolutionizing Precision Bearings

In the world of advanced engineering materials, silicon nitride balls have emerged as a groundbreaking solution. These precision-crafted spheres have revolutionized the concept of bearings, offering superior performance in a multitude of demanding applications.

This blog provides an in-depth look at silicon nitride balls, comparing them with other materials like Zirconia balls, and explores their unique benefits and wide-ranging uses.

Exploring the Properties of Silicon Nitride Balls

Exceptional Hardness and Strength

Silicon nitride balls are noted for their exceptional hardness. They are substantially harder than many types of steel, allowing them to withstand extreme wear and tear in high-stress environments. This hardness translates directly into strength, enabling these balls to handle significant loads without deformation or failure.

Refer to the chart below for a detailed comparison of silicon nitride balls' hardness.

Material Vickers Hardness (HV) Applications

Silicon Nitride (Si3N4) 1,500 - 1,900 High-stress bearings, aerospace, automotive

Steel (AISI 52100) 700 - 800 General bearings, industrial machinery

Zirconia (ZrO2) ~1,200 Corrosive environments, non-magnetic applications

Alumina (Al2O3) 1,300 - 1,700 Chemical resistance, wear applications

Tungsten Carbide (WC) 1,400 - 1,600 Extreme hardness and wear applications

High Thermal Stability

Si3N4 balls stand out because they stay strong and keep their shape even when it gets really hot. Unlike some other materials and metals that might break down or melt, these balls can handle high temperatures and still work well.

Low Density

With a density significantly lower than that of steel, silicon nitride balls offer advantages in reducing the overall weight of the assembly. This property is particularly beneficial in applications where weight savings are critical, such as in aerospace or high-speed applications.

Low Thermal Expansion

Silicon nitride doesn't expand much with heat, so the balls keep their size and shape even when temperatures go up and down. This is key for staying precise and stable in places where the temperature changes a lot.

Wear Resistance

The wear resistance of silicon nitride is superior. This means that in applications such as bearings, these balls will last longer than their metal counterparts, reducing the frequency of replacements and maintenance.

Corrosion Resistance

Silicon nitride balls are chemically inert and offer excellent resistance to corrosion. This makes them suitable for use in harsh environments, including those involving corrosive substances or moisture, where metal balls might suffer degradation.

Electrical Insulation

Another significant property of silicon nitride balls is their electrical insulation capability. They do not conduct electricity, which is essential for preventing electrical erosion in applications such as electric motor bearings.

Non-Magnetic Nature

The non-magnetic nature of Si3N4 makes these balls ideal for use in applications where magnetic interference must be avoided, such as in MRI machines or in semiconductor manufacturing equipment.

Fracture Toughness

Despite their hardness, silicon nitride balls have good fracture toughness, which means they can absorb significant energy before failing, making them resilient against impacts and shocks.

High Elastic Modulus

Silicon nitride balls have a high elastic modulus, indicating that they are very stiff and can restore their shape when deforming forces are removed. This is particularly important for maintaining the precision of mechanical systems under load.

Low Friction Coefficient

The low friction coefficient of Si3N4 reduces energy losses due to friction, enhances efficiency, and minimizes the generation of heat in applications such as high-speed bearings, contributing to the longevity of the systems in which they are used.

Manufacturing Mastery: How Are Silicon Nitride Balls Made?

Silicon nitride balls are crafted using advanced techniques including spray drying granulation, cold isostatic pressing, precision molding, and GPS HIP sintering, complemented by high-efficiency grinding. These processes ensure silicon nitride balls achieve G5 precision (GB/T308 2002) and grade 1 material quality.

Sintering methods for these ceramics include:

Hot Isostatic Pressing (HIP):

- Equal pressure from all directions

- High temperature

- Pressure medium: Nitrogen and argon

- Sintering pressure: 150MPa - 200MPa

Hot Pressing (HP)

- Uniaxial direction pressure

- Pressure: about 70Mpa

- Advantages: Reduces sintering temperature, shortens time, fine grains

- Disadvantages: High sintering pressure, complex process, high cost

Atmospheric Pressure Sintering

- Sintering pressure: 5 to 10 MPa

- Sintering in a specific gas atmosphere

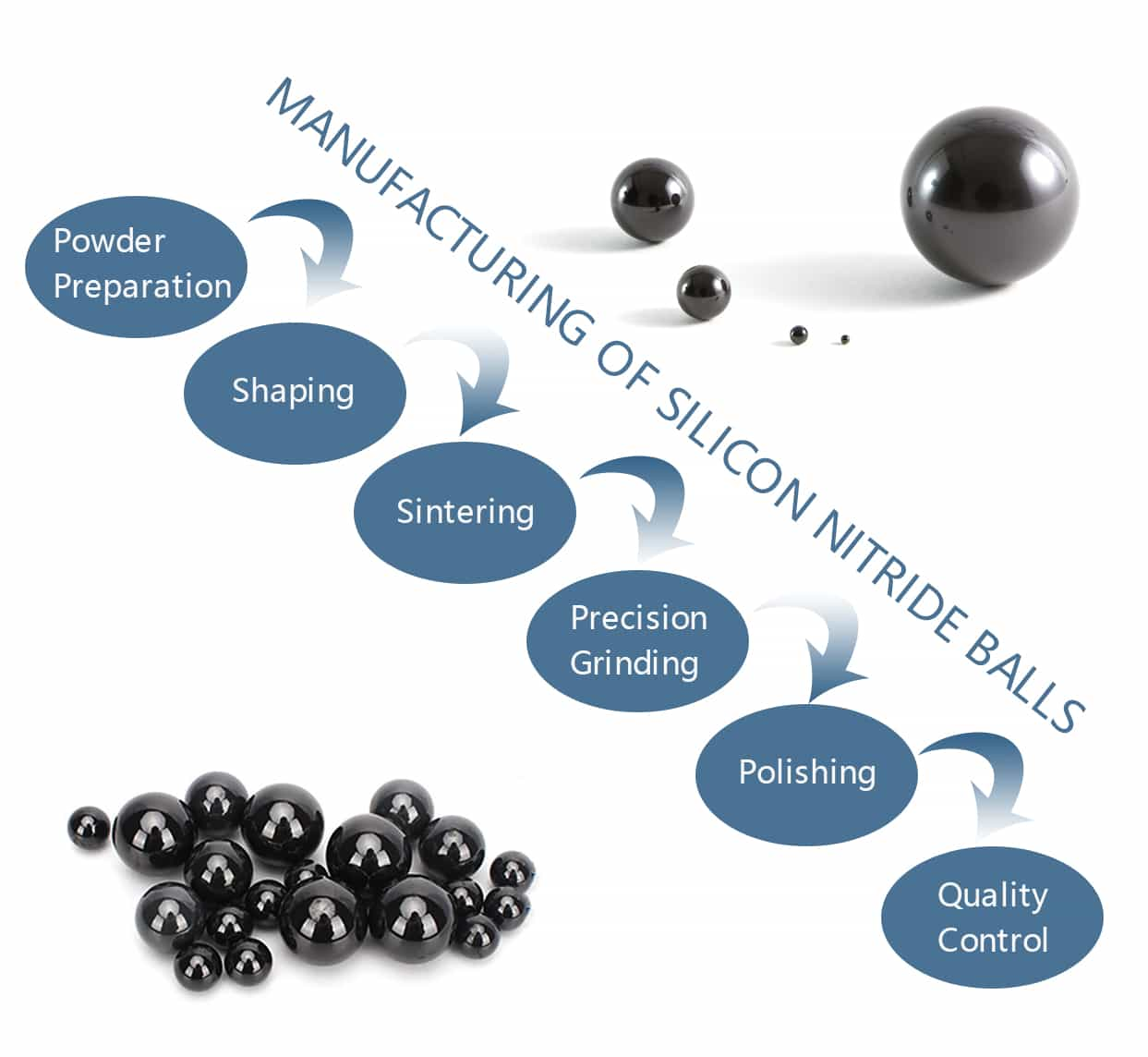

The manufacturing of silicon nitride (Si3N4) balls involves a precise and controlled process to ensure their high performance and durability in demanding applications. Here's a streamlined overview:

- Powder Preparation: High-purity silicon nitride powder, mixed with sintering additives, is prepared for shaping.

- Shaping: The powder is formed into spheres through isostatic pressing, where uniform pressure creates a dense, spherical shape.

- Sintering: The shaped spheres are heated in a nitrogen atmosphere, below their melting point, to bond the particles without melting them, enhancing strength.

- Precision Grinding: Post-sintering, the balls are ground to achieve uniform size and spherical precision, essential for their application in bearings.

- Polishing: A final polishing step ensures a smooth surface, reducing friction and wear in their end use.

- Quality Control: Rigorous inspection for size, surface finish, and material integrity ensures each ball meets stringent specifications.

This streamlined process, from powder to polished product, results in silicon nitride balls with exceptional mechanical properties, suited for high-performance bearing applications.

What is the Use of Silicon Nitride Balls?

Silicon nitride (Si3N4) balls are utilized in a variety of high-demand applications due to their unique properties. Here are some of the primary uses:

- Bearings: Silicon nitride balls are widely used in both full ceramic bearings and hybrid bearings. Their high hardness and low density reduce wear and tear, allowing for higher speed operations and longer service life. This makes them ideal for applications in the aerospace, automotive, and industrial sectors.

- High-Speed Applications: The low weight of silicon nitride reduces centrifugal forces in high-speed rotations, making these balls suitable for high-speed spindles in machine tools, as well as in high-speed dental drills.

- Electric Motors: Their electrical insulating properties prevent electric arcing in bearings, extending the life of bearings used in electric motors, including those in electric and hybrid vehicles.

- Corrosive Environments: The chemical inertness of silicon nitride enables its use in corrosive environments, such as in chemical processing equipment, without degradation.

- High Temperature Applications: Silicon nitride balls maintain their strength and hardness at high temperatures, making them suitable for use in high-temperature gas turbines and other applications where thermal resistance is crucial.

- Medical Devices: Their non-magnetic nature allows for their use in medical imaging equipment, such as MRI machines, where magnetic materials could interfere with the imaging process.

Why Silicon Nitride is Used in Ball Bearings?

Silicon nitride bearings are the epitome of innovation in high-performance bearing technology. With exceptional strength, durability, and resistance to wear and high temperatures, silicon nitride balls outshine traditional steel bearings. These properties enable the ceramic ball bearings to operate with less friction, reduced wear, and at higher speeds, making them ideal for industries seeking efficiency and longevity.

ZrO2 vs Si3N4 balls: An In-Depth Comparison

Property ZrO2 (Zirconia) Si3N4 (Silicon Nitride)

Hardness (Vickers) ~1200 HV ~1500-1800 HV

Density (g/cm³) ~6.0 ~3.2

Thermal Stability (°C) Up to 1000 Up to 1200

Wear Resistance Good Superior

Corrosion Resistance Excellent Excellent

Fracture Toughness (MPa·m½) ~10 ~6-7

Electrical Insulation Yes Yes

Magnetic Properties Non-magnetic Non-magnetic

Price Comparison Lower Higher

Application Examples Valves, pump liners High-speed bearings, automotive components

Conclusion

Silicon Nitride (Si3N4) balls represent a pinnacle of engineering excellence, embodying the perfect blend of durability, performance, and efficiency required by cutting-edge industries. At LILY Bearing, we are proud to offer a premium selection of Silicon Nitride balls, meticulously designed to meet the rigorous demands of various applications. Visit us today to learn more about our Silicon Nitride balls and how they can revolutionize your applications.

Keep Learning