Mounted Bearings: Types, Advantages, and Uses

In the world of machinery, mounted bearings play a pivotal role. They are integral to the smooth operation of various equipment across industries. Understanding mounted bearings, their types, advantages, and applications, is crucial. This knowledge aids in selecting the right bearing for specific needs.

This article aims to provide a comprehensive overview of mounted bearings. From ball bearings to roller bearings, we'll delve into the different types available. We'll also explore the advantages of using mounted bearings. Their performance, even in the harshest environments, makes them a preferred choice in many applications.

From industrial machinery to food-grade applications, we'll discuss where these bearings find their use. We'll also touch upon the importance of proper bearing fitting and maintenance for optimal performance. Join us as we navigate the world of mounted bearings, helping you make informed decisions for your machinery needs.

What Are Mounted Bearings?

Mounted bearings, also known as bearing units, are a type of rolling-element bearing. They are unique in that they come pre-assembled with a bearing housing.

The bearing housing, often made of cast iron or stainless steel, provides support and protection to the bearing. This design allows for easier installation and maintenance, making mounted bearings a popular choice in various industrial applications.

Types of Mounted Bearings

Mounted bearings come in various types, each suited for specific applications. Here are some of the most common types and their uses:

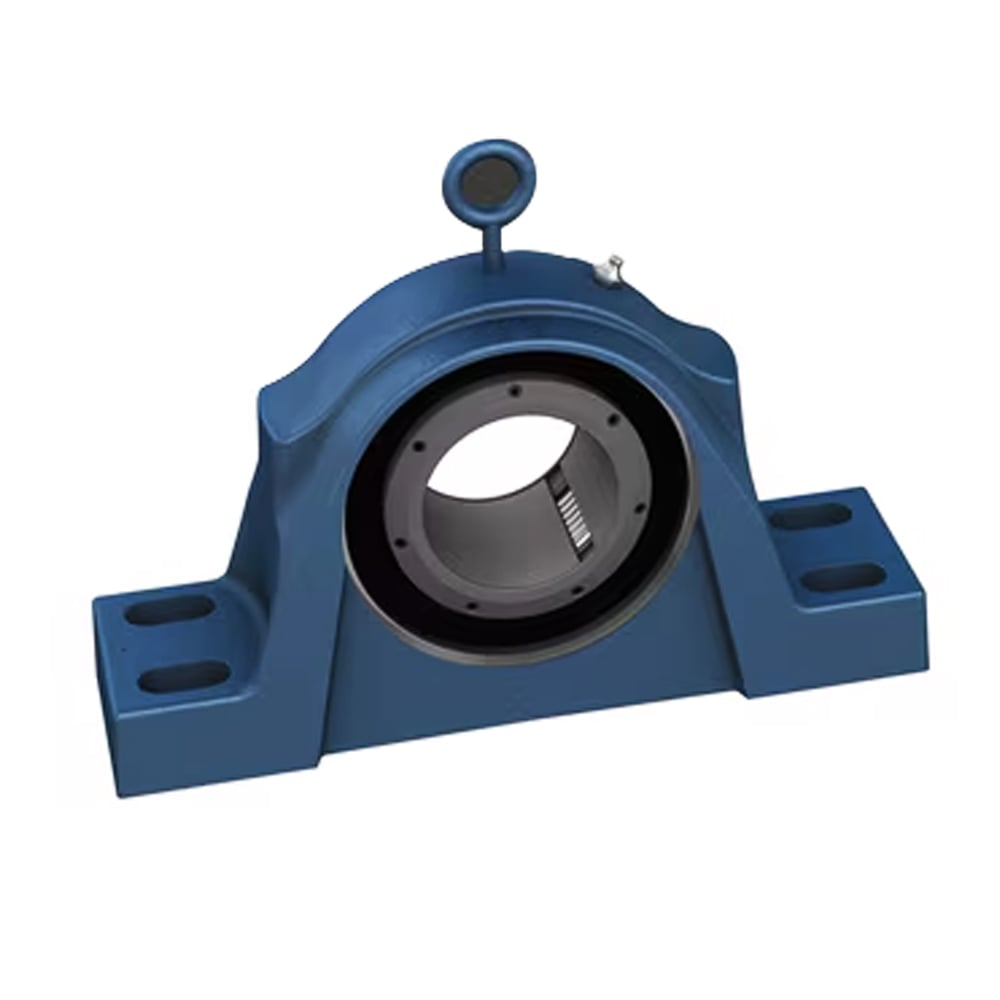

- Pillow Block Bearings/Mounted Bearing Units: These bearings are mounted in a housing that can be bolted to a structure. They are used in applications where the shaft axis is parallel to the mounting surface.

Mounted Bearing Units

- Flange Mount Bearings: Flange mount bearings come with a flange on the outer ring, typically with holes for easy mounting. They are used when the shaft axis is perpendicular to the mounting surface.

- Take-Up Unit Bearings: These bearings are used in applications where there is a need for tension adjustment. They are commonly found in conveyor systems where precise alignment and tensioning are necessary.

- Hanger Bearings: Hanger bearings are used in conveyor systems to support the shaft and allow it to rotate freely. They are often used in applications where space constraints prevent the use of pillow block or flange mount bearings.

- Insert Bearings/ Mounted Bearing Inserts: Insert bearings are standalone bearings that can be placed into a housing. They are versatile and can be used in various types of housings, offering flexibility in design and maintenance.

- Corrosion Protection Bearing Units/Inserts: These are specifically designed to withstand harsh environments. They are typically made from stainless steel or coated with materials to prevent corrosion, making them suitable for food processing, marine, and chemical applications.

Advantages of Mounted Bearings

Mounted bearings offer several advantages that make them a preferred choice for many industrial applications. One of the main benefits is their ease of installation.

Mounted bearings come pre-assembled with the bearing and housing, which simplifies the installation process. This feature can significantly reduce downtime and increase productivity in industrial settings.

Another advantage is their flexibility. Mounted bearings are available in a wide range of sizes, types, and materials to suit different applications. Use a ball bearing for high-speed applications. Use a roller bearing for high-load applications.

- Ease of installation

- Flexibility

- Durability

- High load capacity

Moreover, mounted bearings offer durability and high load capacity. Their design withstands harsh conditions and heavy loads, making them ideal for heavy-duty applications.

Lastly, many mounted bearings have seals and shields to prevent dirt. This feature enhances their lifespan and performance.

Bearing Performance and Fitting

Several factors influence the performance of mounted bearings, including the bearing type, material, and fitting. Proper bearing fitting is crucial for optimal performance and longevity.

Incorrect fitting can lead to premature bearing failure, increased maintenance costs, and downtime. Ensure you correctly align and securely fit the bearing to the shaft and housing.

The material of the bearing also plays a significant role in its performance. For instance, stainless steel bearings resist corrosion, making them suitable for harsh environments. On the other hand, thermoplastic bearings are lightweight and resistant to chemicals, making them ideal for food-grade applications.

Applications of Mounted Bearings

Mounted bearings are widely used in various industries due to their versatility and durability. They are integral components in many types of machinery, providing support and reducing friction between moving parts.

Industrial Machinery

In industrial machinery, mounted bearings are used to support rotating shafts and absorb loads. They are found in everything from conveyor systems to electric motors. Their robust design and ease of maintenance make them ideal for these applications.

Food Grade Applications

Food grade mounted bearings are designed to withstand the rigorous cleaning processes in the food and beverage industry. They are often made of stainless steel or thermoplastic materials that resist corrosion and are easy to clean.

Harsh Environments

Certain types of mounted bearings are designed to perform even in the harshest environments. These bearings are made from materials that can resist extreme temperatures, heavy loads, and corrosive substances.

Automation and Robotics

In the field of automation and robotics, precision is key. Mounted bearings, especially linear and ball bearings, provide the high precision and control required in these applications. They ensure smooth and accurate movement, making them essential in this rapidly growing field.

Selecting the Right Mounted Bearing

Choosing the right mounted bearing is crucial for optimal performance and longevity of your machinery. Several factors need to be considered during the selection process.

- The type of load and speed the bearing will be subjected to must be taken into account. Different types of bearings are designed to handle different loads and speeds. For example, roller bearings handle heavy radial loads better, while ball bearings are ideal for high-speed applications.

- Furthermore, the operating environment is also a key consideration. Bearings for harsh environments or food-grade applications have specific features. They include corrosion resistance or easy-to-clean materials, making them suitable for these conditions.

Maintenance and Longevity of Mounted Bearings

Proper maintenance is key to ensuring the longevity of mounted bearings. Regular inspection and lubrication can significantly extend the lifespan of these components.

Lubrication reduces friction and wear, preventing premature failure. Use the correct type and amount of bearing lubricant as specified by the bearing manufacturer.

Protect bearings from dirt and excessive heat to prevent lubricant degradation and bearing damage. Use sealed or shielded bearings to avoid dirt, and select bearings with proper heat resistance to handle high temperatures.

Conclusion

Mounted bearings play a crucial role in various industries, offering numerous advantages such as durability, flexibility, and improved performance. Understanding their types, applications, and maintenance requirements can help in selecting the right bearing for your needs.

In a world that increasingly relies on machinery, the importance of these components are incredibly important. They are truly the unsung heroes of the industrial world.

Keep Learning