Cancel

W 619/1 R

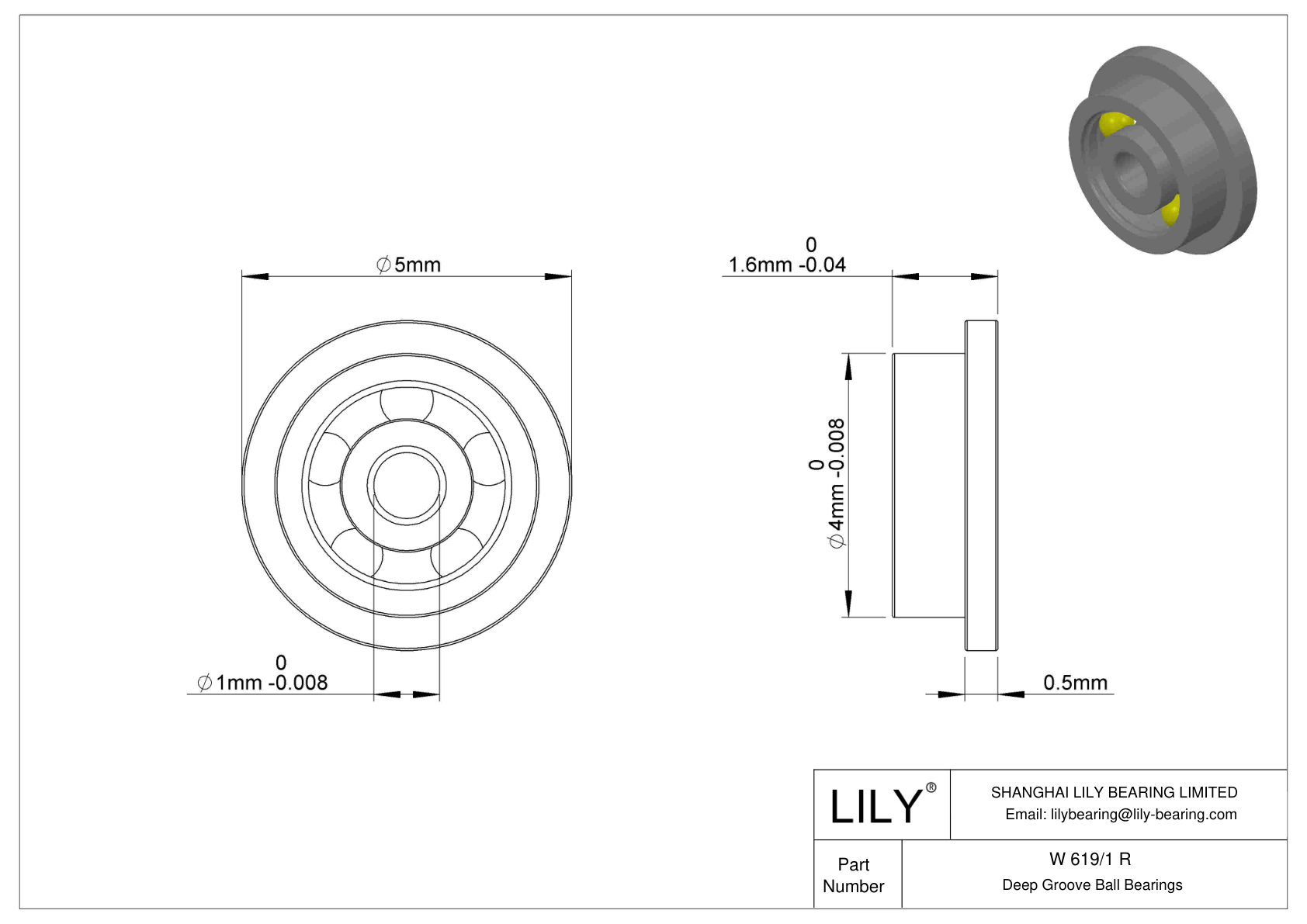

| Part Number | W 619/1 R |

Brand: LILY  | |

Equivalent: SKF |

| System of Measurement | Metric |

| Bearing Type | Ball |

| For Load Direction | Radial |

| Construction | Single Row |

| Seal Type | Open |

| Bore Dia | 1 mm |

| Bore Dia Tolerance | -0.008mm to 0 |

| Outer Dia | 4 mm |

| Outer Dia Tolerance | -0.008mm to 0 |

| Width | 1.6 mm |

| Width Tolerance | -0.04mm to 0 |

| Flange Outer Dia | 5 mm |

| Flange Thickness | 0.5 mm |

| Ring Material | Stainless Steel |

| Ball Material | Stainless Steel |

| Cage Material | Stainless Steel |

| Dynamic Radial Load | 18 lbf |

| Static Radial Load | 4 lbf |

| Max Speed (X1000 rpm) | 140 |

| Lubrication | None |

| Temperature Range | -30° to 120 °C |

| ABEC Rating | P0 |

| Radial Internal Clearance | CN |

| RoHS | Compliant |

| REACH | Compliant |

| Weight | 0.0001 kg |

Design Features of W 619/1 R Bearing

W 619/1 R Bearing is designed to facilitate both radial and axial loads. It comes equipped with a flange on the outer ring, providing a mechanism for easy mounting and dismounting, as well as better axial location of the bearing. W 619/1 R bore dia is 1 mm. Its out dia is 4 mm. W 619/1 R flange diameter is Flange_Diameter. Constructed from high-quality materials like chrome steel or stainless steel, W 619/1 R Bearing is employed across a range of industries.

What Benefits Can W 619/1 R Bearing Provide?

W 619/1 R Bearing can provide the following key features:

- Easy Mounting: Integral flange simplifies installation, ideal for limited space.

- Axial Location: Built-in thrust surface for excellent axial stability.

- High Load Capacity: Designed for high radial and axial load resilience.

- Durability: Made from robust materials for long-lasting performance.

- Low Maintenance: Advanced seals reduce contamination and upkeep.

What Can W 619/1 R Bearing Be Used for?

W 619/1 R Bearing is versatile and can be used in a variety of applications, including but not limited to:

- Electrical Motors: In both AC and DC motors for better performance and reduced maintenance.

- Agricultural Machinery: In tractors, harvesters, and other heavy-duty equipment to withstand tough environmental conditions.

- Pumps and Compressors: To ensure smooth operation and longevity.

- Home Appliances: In washing machines, air conditioners, and even in smaller gadgets like electric fans.

- Medical Equipment: Utilized in devices like MRI machines, where low friction and high reliability are essential.

Recommended Products