Cancel

SMF63C-Y AF2

Price $ 4.87

Number

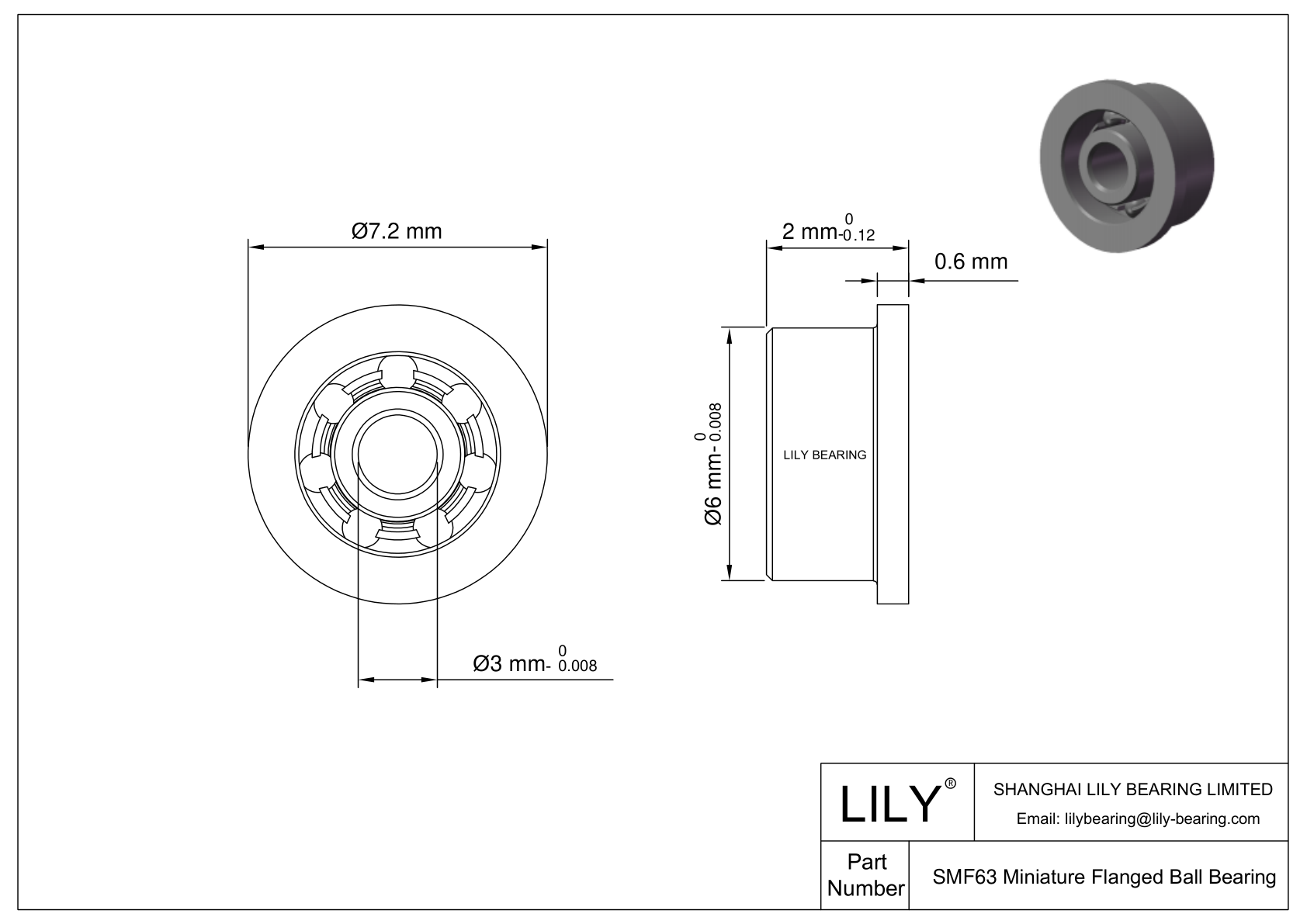

| Part Number | SMF63C-Y AF2 |

| System of Measurement | Metric |

| Bearing Type | Ball |

| For Load Direction | Radial |

| Construction | Single Row |

| Inner Ring Type | Standard |

| Seal Type | Open |

| Bore Dia | 3 mm |

| Outer Dia | 6 mm |

| Width | 2 mm |

| Flange Outer Dia | 7.2 |

| Flange Thickness | 0.6 |

| Ring Material | 440C Stainless Steel |

| Balls Material | Si3n4 |

| Cage Material | Stainless Steel |

| Lubrication | Shell Af2 Oil |

| Shaft Mount Type | Press Fit |

| Temperature Range | -86 to 230 °F |

| ABEC Rating | Abec#1/isop0 |

| Radial Clearance Trade No | MC3 (Available in MC1/2/4/5/6) |

| Ball Grade | 10 |

| RoHS | Compliant |

| REACH | Compliant |

Design Features of SMF63C-Y AF2 Bearing

SMF63C-Y AF2 Bearing seamlessly merges the distinct benefits of ceramic and steel components. The core of this bearing employs ceramic balls, housed within steel races. SMF63C-Y AF2 bore dia is 3 mm. Its out dia is 6 mm. SMF63C-Y AF2 width is 2 mm. The Flanged design further allows for easy positioning, leading to faster assembly and alignment, especially in applications where axial location is critical.

What Benefits Can SMF63C-Y AF2 Bearing Provide?

- High-Speed Efficiency: Lighter ceramic elements enable faster operation with reduced centrifugal force.

- Enhanced Durability: Ceramic resists wear and handles high temperatures, extending service life.

- Reduced Friction: Ceramic balls reduce overall friction, lowering operational temperatures.

- Electrical Insulation: Prevents electrical arcing or current passage through the bearing.

- Corrosion Resistance: Ceramic's inertness ensures resistance to corrosive environments.

- Precise Positioning: Flanged design allows for accurate axial location and stability, simplifying assembly processes.

What Can SMF63C-Y AF2 Bearing Be Used for?

SMF63C-Y AF2 Bearing is primarily used in applications requiring the combined benefits of ceramic and steel components, along with precise mounting capabilities. Its applications include:

- Electric Motors: It provides electrical insulation, preventing electrical erosion.

- High-Speed Machinery: Its low density and high hardness enable efficient high-speed operation.

- Precision Equipment: Used in CNC machines and precision instruments for enhanced accuracy and low friction.

- Automotive: Beneficial in high-performance and electric vehicles for efficiency and speed.

- Robotics: This bearing Offers precision, low friction, and durability, crucial for robotics.

- Pumps and Compressors: Improve efficiency and longevity due to reduced friction and wear resistance.

Recommended Products

})