Cancel

NU 312 ECM/HC5C3

Price $ 900.00

Number

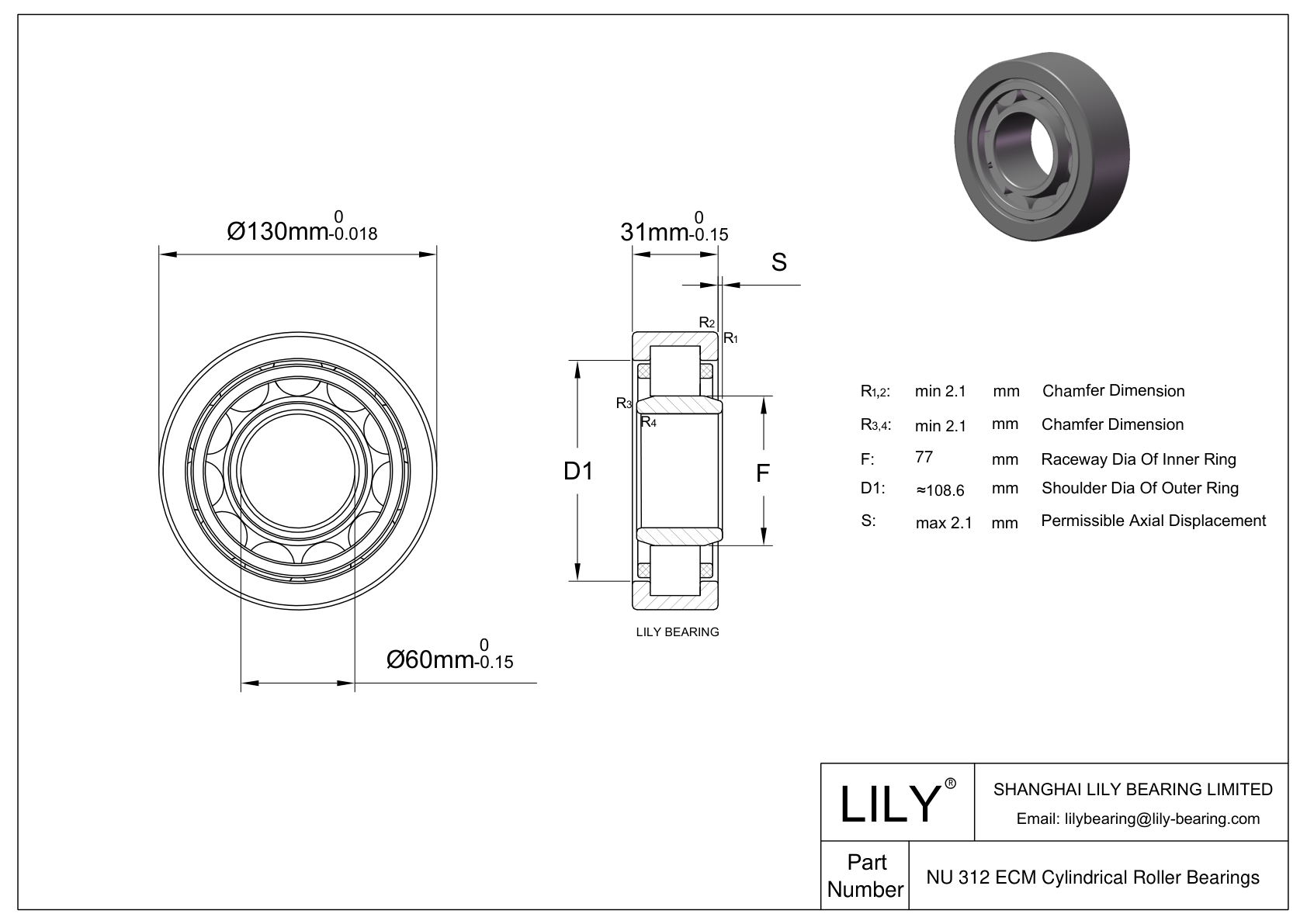

| Part Number | NU 312 ECM/HC5C3 |

| System of Measurement | Metric |

| Bearing Type | Ball |

| For Load Direction | Radial |

| Construction | Single Row |

| Inner Ring Type | Standard |

| Seal Type | Open |

| Bore Dia | 60 mm |

| Outer Dia | 130 mm |

| Width | 31 mm |

| Ring Material | Chrome Steel |

| Balls Material | Si3n4 |

| Dynamic Radial Load | 33946 lbf |

| Static Radial Load | 35969 lbf |

| Max Speed (X1000 rpm) | 8 |

| Lubrication | Required |

| Shaft Mount Type | Press Fit |

| Temperature Range | -86 to 230 °F |

| Radial Clearance Trade No | MC3 (Available in MC1/2/4/5/6) |

| Reference Speed | 5000 r/min |

| Calculation Factor | 0.15 |

| RoHS | Compliant |

| REACH | Compliant |

| Weight | 1.43 kg |

| Chamfer Dimension (r1 2)(min) | 2.1 mm |

| Fatigue Load Limit (Pu) | 18 kN |

| Abutment Diameter Shaft (da)(min) | 72 mm |

| Abutment Diameter Shaft (da)(max) | 74 mm |

| Abutment Diameter Housing (Da)(max) | 118.1 mm |

| Fillet Radius (ra)(max) | 2 mm |

| Shoulder Diameter Outer Ring (D1) | 110 mm |

| Raceway Diameter Inner Ring (F) | 77 mm |

| Permissible Axial Displacement(s)(max) | 2.1 mm |

| Chamfer Dimension (r3,4)(min) | 2.1 mm |

| Abutment Diameter Shaft (db)(min) | 79 mm |

| Fillet Radius (rb)(max) | 2 mm |

Design Features of NU 312 ECM/HC5C3 Bearing

NU 312 ECM/HC5C3 Bearing blends the robustness of steel with the superior properties of ceramic. NU 312 ECM/HC5C3 bore dia is 60 mm. Its out dia is 130 mm. NU 312 ECM/HC5C3 width is 31 mm. The inner ring and the outer ring are typically made of high-grade bearing steel. Its rollers are made of ceramic materials, most commonly silicon nitride (Si3N4). Ceramic rollers are lighter and harder than their steel counterparts.

What Benefits Can NU 312 ECM/HC5C3 Bearing Provide?

- High-Speed Capability: Ceramic rollers enable higher operational speeds with reduced centrifugal force.

- Wear Resistance: The hardness of ceramics extends bearing life by minimizing wear.

- Thermal Stability: Better temperature regulation due to lower thermal expansion of ceramic materials.

- Reduced Friction: Smoother ceramic surfaces lower friction, enhancing efficiency and reducing heat generation.

- Electrical Insulation: Non-conductive ceramics prevent electrical erosion in bearings.

- Corrosion Resistance: Suitable for chemically aggressive environments.

What Can NU 312 ECM/HC5C3 Bearing Be Used for?

NU 312 ECM/HC5C3 Bearing is ideal for applications requiring high performance under demanding conditions, such as:

- High-Speed Machinery: Perfect for machine tools and spindles due to its high-speed capability.

- Electric Motors and Generators: Its electrical insulation properties protect against electrical erosion.

- Aerospace Industry: Used for its reliability and thermal stability in varying conditions.

- Medical Equipment: Essential in high-precision devices like MRI and CT scanners for its low interference and high-speed operation.

- Automotive Industry: Suitable for high-performance and electric vehicles, offering efficiency and durability.

Recommended Products

})