Cancel

FR168C-GSZ SRL

Price $ 2.51

Number

| Part Number | FR168C-GSZ SRL |

| System of Measurement | Inch |

| Bearing Type | Ball |

| For Load Direction | Radial |

| Construction | Single Row |

| Inner Ring Type | Standard |

| Seal Type | Shielded |

| Seal No | One Seal One Shield |

| Seal Material | Shield/seal |

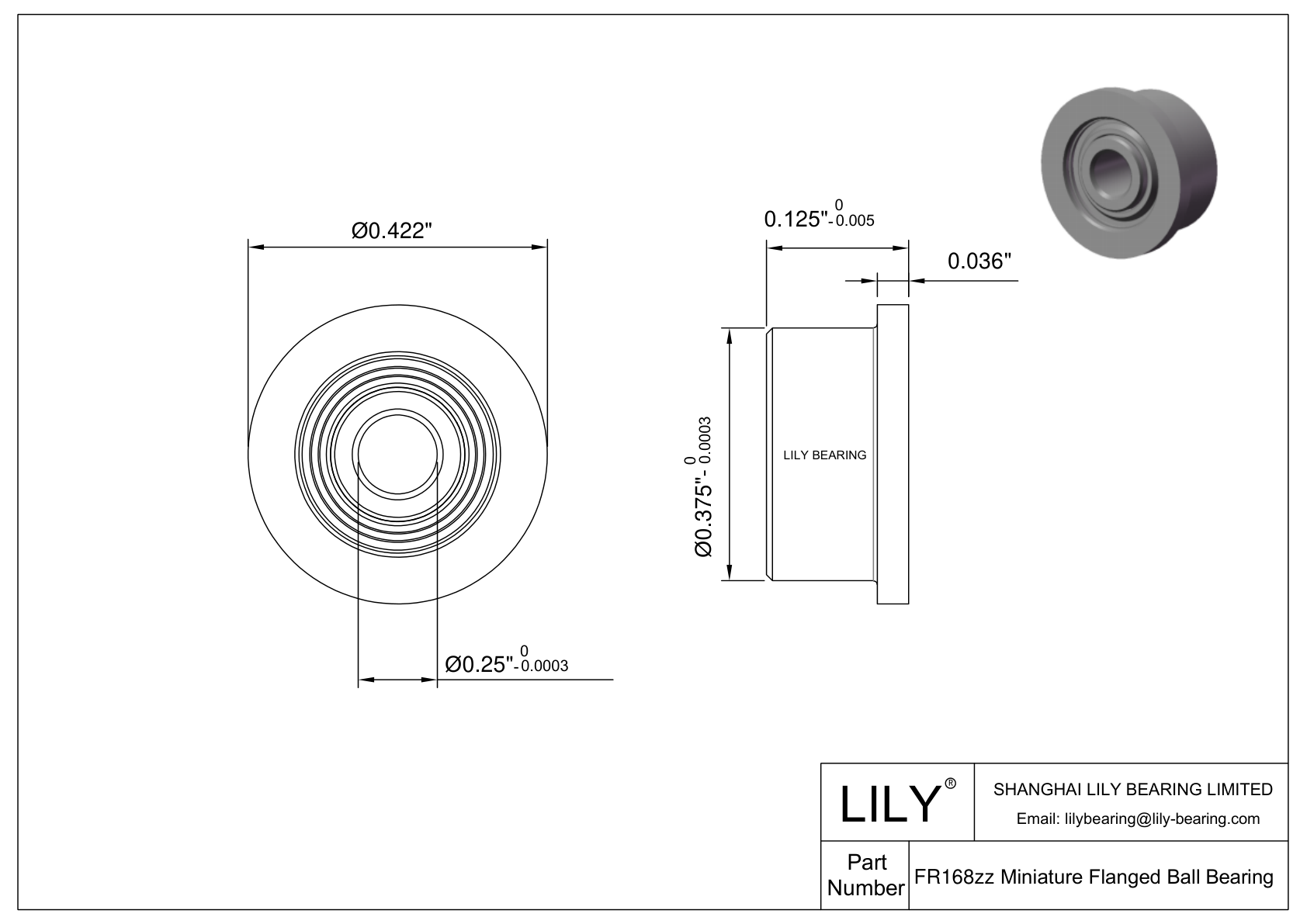

| Bore Dia | 0.25" |

| Outer Dia | 0.375" |

| Width | 0.125" |

| Flange Outer Dia | 0.4219 |

| Flange Thickness | 0.036 |

| Ring Material | Chrome Steel |

| Balls Material | Si3n4 |

| Cage Material | Chrome Steel |

| Dynamic Radial Load | 84 lbf |

| Static Radial Load | 40 lbf |

| Max Speed (X1000 rpm) | 56 |

| Lubrication | Kyodo Srl Grease |

| Shaft Mount Type | Press Fit |

| Temperature Range | -86 to 230 °F |

| ABEC Rating | Abec#1/isop0 |

| Radial Clearance Trade No | MC3 (Available in MC1/2/4/5/6) |

| Ball Grade | 10 |

| RoHS | Compliant |

| REACH | Compliant |

Design Features of FR168C-GSZ SRL Bearing

FR168C-GSZ SRL Bearing seamlessly merges the distinct benefits of ceramic and steel components. The core of this bearing employs ceramic balls, housed within steel races. FR168C-GSZ SRL bore dia is 0.25". Its out dia is 0.375". FR168C-GSZ SRL width is 0.125". The Flanged design further allows for easy positioning, leading to faster assembly and alignment, especially in applications where axial location is critical.

What Benefits Can FR168C-GSZ SRL Bearing Provide?

- High-Speed Efficiency: Lighter ceramic elements enable faster operation with reduced centrifugal force.

- Enhanced Durability: Ceramic resists wear and handles high temperatures, extending service life.

- Reduced Friction: Ceramic balls reduce overall friction, lowering operational temperatures.

- Electrical Insulation: Prevents electrical arcing or current passage through the bearing.

- Corrosion Resistance: Ceramic's inertness ensures resistance to corrosive environments.

- Precise Positioning: Flanged design allows for accurate axial location and stability, simplifying assembly processes.

What Can FR168C-GSZ SRL Bearing Be Used for?

FR168C-GSZ SRL Bearing is primarily used in applications requiring the combined benefits of ceramic and steel components, along with precise mounting capabilities. Its applications include:

- Electric Motors: It provides electrical insulation, preventing electrical erosion.

- High-Speed Machinery: Its low density and high hardness enable efficient high-speed operation.

- Precision Equipment: Used in CNC machines and precision instruments for enhanced accuracy and low friction.

- Automotive: Beneficial in high-performance and electric vehicles for efficiency and speed.

- Robotics: This bearing Offers precision, low friction, and durability, crucial for robotics.

- Pumps and Compressors: Improve efficiency and longevity due to reduced friction and wear resistance.

Recommended Products

})