F681

| Part Number | F681 |

| System of Measurement | Metric |

| Bearing Type | Ball |

| For Load Direction | Radial |

| Construction | Single Row |

| Inner Ring Type | Standard |

| Seal Type | Open |

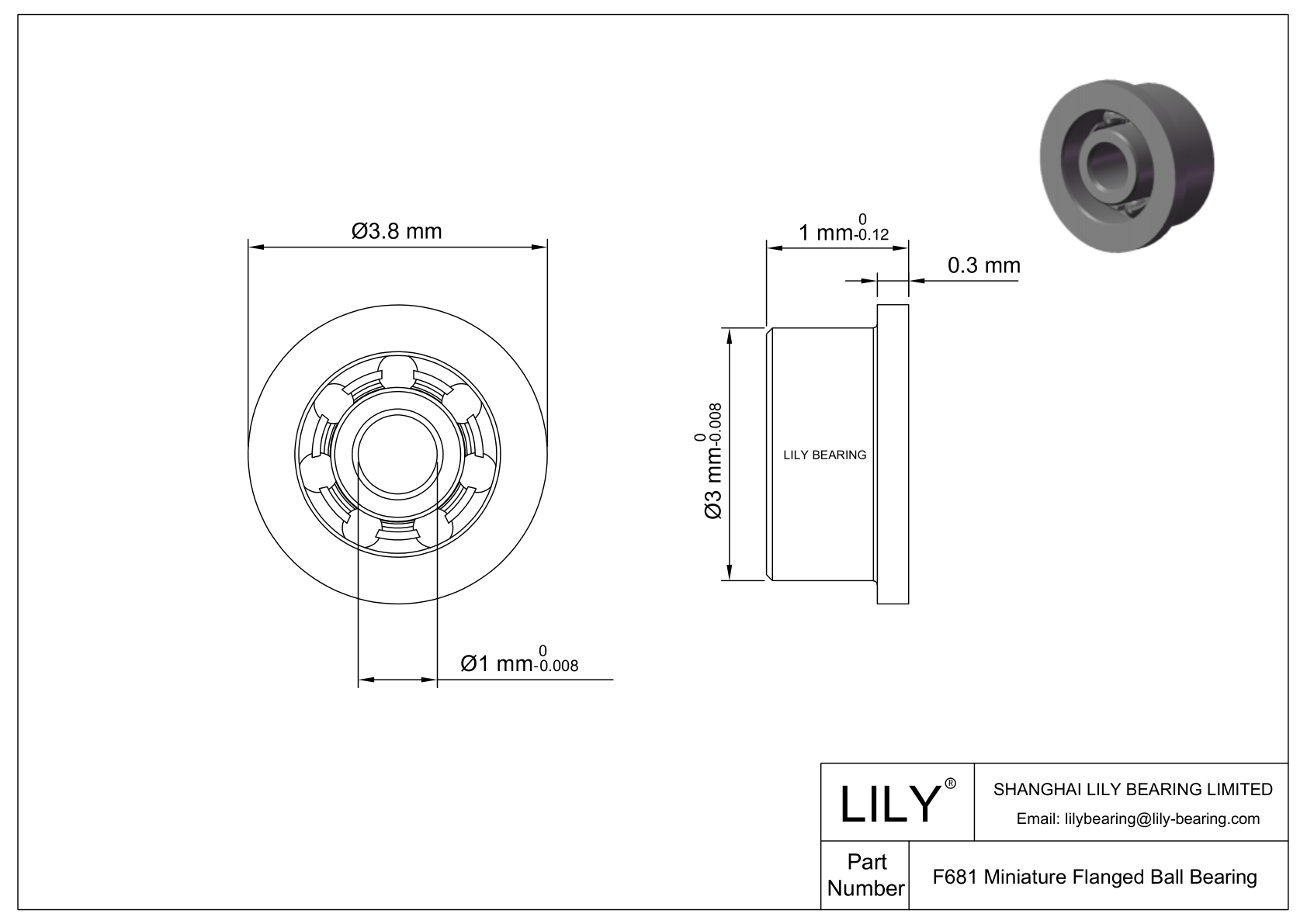

| Bore Dia | 1 mm |

| Bore Dia Tolerance | -0.008mm to 0 |

| Outer Dia | 3 mm |

| Outer Dia Tolerance | -0.008mm to 0 |

| Width | 1 mm |

| Width Tolerance | -0.12mm to 0 |

| Flange Outer Dia | 3.8 mm |

| Flange Thickness | 0.3 mm |

| Ring Material | Chrome Steel |

| Ball Material | Chrome Steel |

| Cage Material | 300 Series Stainless Steel |

| Dynamic Radial Load | 18 lbf |

| Static Radial Load | 5 lbf |

| Max Speed (X1000 rpm) | 130 |

| Lubrication | Required |

| Shaft Mount Type | Press Fit |

| Temperature Range | -30° to 110 °C |

| ABEC Rating | ABEC1 |

| Radial Clearance Trade No | MC3 |

| Radial Clearance | 0.002mm to 0.013mm |

| RoHS | Compliant |

| REACH | Compliant |

| Ball Dia | 0.6000 mm |

| Ball Qty | 6 |

| Weight | 0.04 g |

Design Features of F681 Bearing

F681 Bearing is engineered with an outer flange that serves to locate the bearing in a housing or offer additional support to the bearing. This unique design enables trouble-free installation and dependable performance in restricted areas. The flange also helps to maintain bearing alignment and protects against axial loads. F681 bore dia is 1 mm. Its out dia is 3 mm. F681 ball material is Chrome Steel. Its seal type is Open. Designed to deliver exceptional performance and reliability in precision applications, This bearing is engineered to meet demanding requirements.

Applications of F681 Bearing

F681 Bearing are versatile components that can be used in various industrial applications, including Pulmonary assist devices, Clocks, Instrumentation. It is also suitable for use in Gas Meters, Industrial Encoders, Industrial Meters, Optical Encoders, etc. Its compact size, low friction, and precise operation make it an ideal choice for applications where space is limited, and performance and reliability are essential. Additionally, its ability to operate at high speeds and handle radial and axial loads makes it well-suited for a wide range of applications.

Maintenance and Troubleshooting Tips of F681 Bearing

Maintaining and troubleshooting F681 Bearing is critical for ensuring optimal performance and long lifespan. Consistent inspections for signs of wear, damage, or contamination are necessary, followed by cleaning with a non-corrosive solvent and thorough drying before lubrication. Replace the bearing immediately if there are indications of damage or excessive wear. Troubleshooting any application problems is also important to ensure that the bearing operate within its designed parameters, reducing the risk of premature failure or damage.

})