F49M

| Part Number | F49M |

Brand: LILY  | |

Equivalent: DYNAROLL |

| System of Measurement | Metric |

| Bearing Type | Ball |

| Washers Type | grooved raceway |

| For Load Direction | Thrust |

| Inner Ring Type | Standard |

| Seal Type | Open |

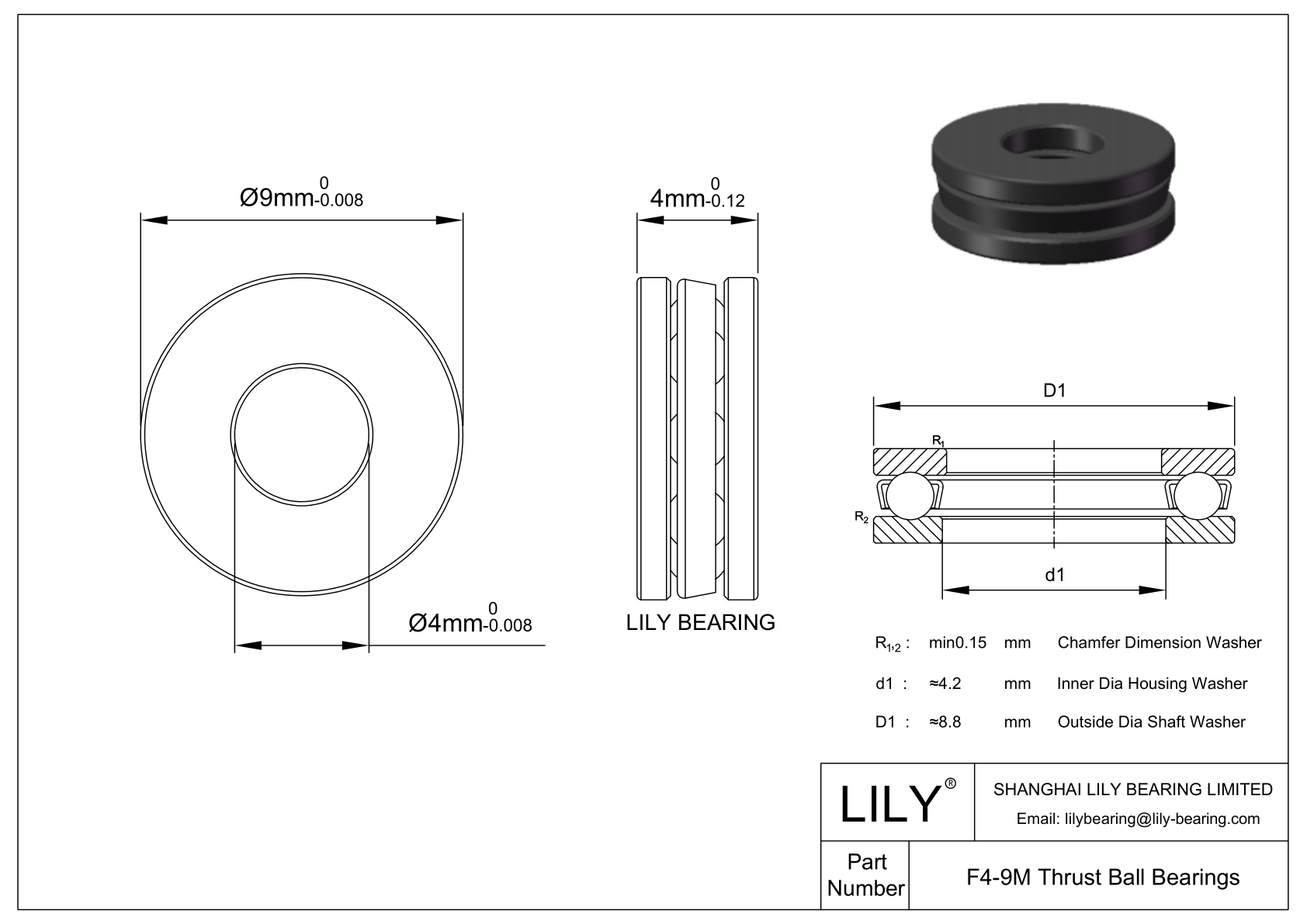

| Bore Dia | 4 mm |

| Bore Dia Tolerance | -0.008mm to 0 |

| Outer Dia | 9 mm |

| Outer Dia Tolerance | -0.008mm to 0 |

| Housing Washer ID | 4.2 mm |

| Shaft Washer OD | 8.8 mm |

| Height | 4 mm |

| Height Tolerance | -0.12mm to 0 |

| Washer Material | Chrome Steel |

| Ball Material | Chrome Steel |

| Cage Material | Bronze |

| Dynamic Thrust Load | 800 N |

| Static Thrust Load | 520 N |

| Max Speed (X1000 rpm) | 8 |

| Lubrication | Required |

| Temperature Range | -30° to 110 °C |

| RoHS | Compliant |

| REACH | Compliant |

| Ball Dia | 1.588 mm |

| Ball Qty | 6 |

| Weight | 1.2 g |

Design Features of F49M Bearing

F49M Bearing is typically made up of two washers and a ball cage assembly. The washers are designed to support axial loads while the ball cage assembly allows the bearing to handle high-speed rotation with minimal friction. F49M bore dia is 4 mm. Its out dia is 9 mm. F49M ball material is Chrome Steel. Its seal type is Open. F49M Bearing is an ideal choice for industries where axial loads and high speeds are required in small spaces.

Applications of F49M Bearing

F49M Bearing is widely used in various industries where axial loads are required to be supported with high precision and low friction. This bearing finds applications in automotive transmissions, electric motors, aerospace equipment, and medical equipment. It is also used in household appliances, power tools, and machine tools, among others. Due to its compact size and efficient performance, F49M Bearing is an ideal choice for applications with limited space and high axial load requirements.

Maintenance and Troubleshooting Tips of F49M Bearing

Regular maintenance is crucial for optimal performance and durability of F49M Bearing. Regularly inspect for wear, damage, or contamination, and clean with a non-corrosive solvent and dry thoroughly before lubrication. Ensure proper alignment and sufficient lubrication to avoid premature failure. Troubleshoot any application issues and replace the bearing if there is excessive wear or damage. Required is also essential for smooth operation.