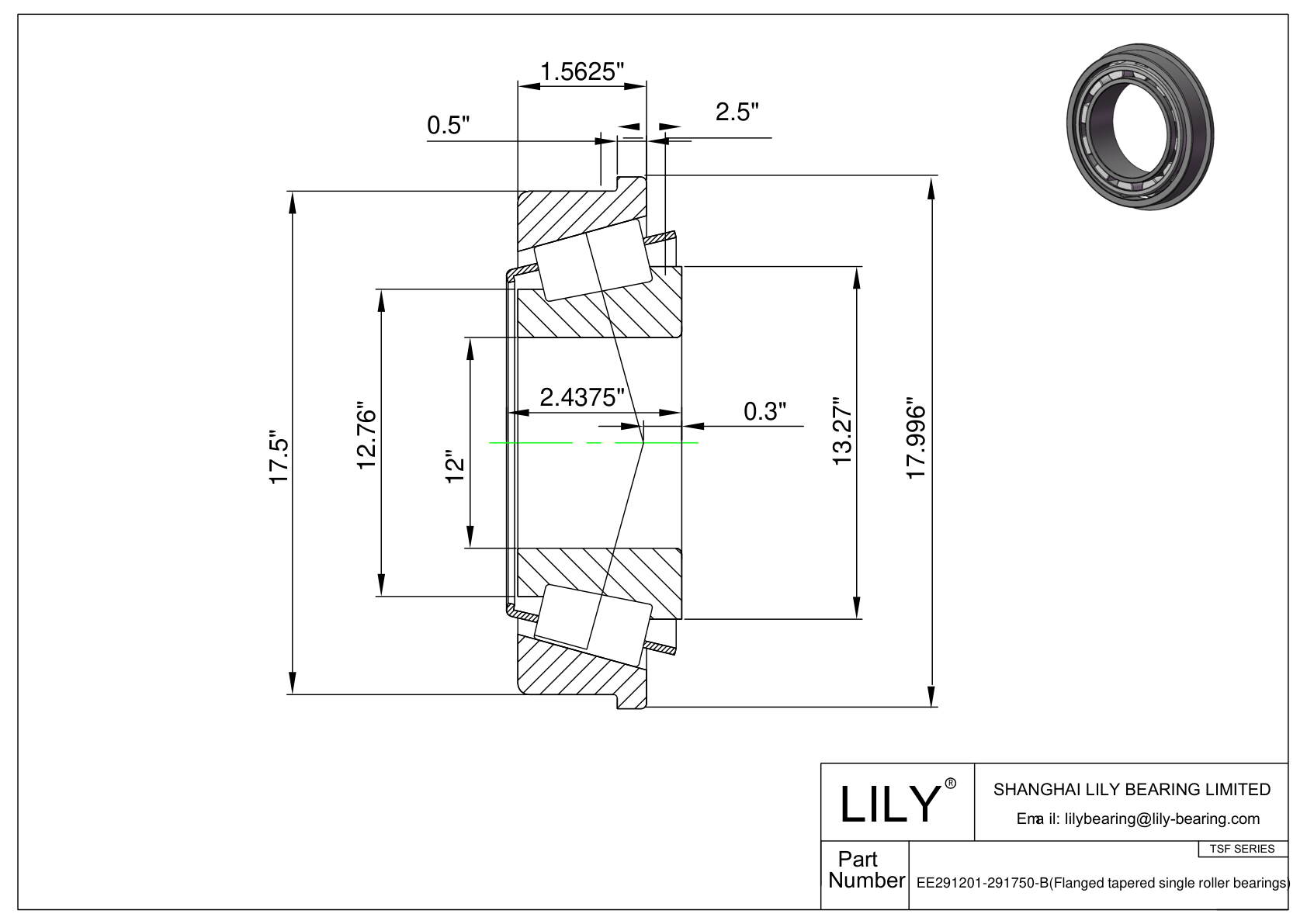

EE291201-291750-B

| Part Number | EE291201-291750-B |

Brand: LILY  | |

Equivalent: Timken |

| System of Measurement | Inch |

| Type | Bearing |

| Cone Part Number | EE291201 |

| Cup Part Number | 291750-B |

| Bearing Type | Roller |

| Roller Bearing Type | Tapered Roller |

| For Load Direction | Combined |

| Construction | Single Row |

| Seal Type | Open |

| Cups Type | Flanged |

| Series | 290000 |

| Bore Dia | 12" |

| Bore Dia Tolerance | +0.001" to 0 |

| Outer Dia | 17.5" |

| Outer Dia Tolerance | +0.002" to 0 |

| Cone Width | 2.4375" |

| Cone Width Tolerance | +0.003" to -0.01 |

| Cup Width | 1.5625" |

| Cup Width Tolerance | +0.002" to -0.01 |

| Flange Outer Diameter(D1) | 17.996" |

| Cup Flange Width(C1) | 0.5" |

| Flange Bearing Width(T1) | 2.5" |

| Cone Backface ToClear Radius | 0.310" |

| Cup Backface ToClear Radius | 0.06" |

| Cone Frontface Backing Diameter | 12.76" |

| Cone Backface Backing Diameter | 13.27" |

| Cup Frontface Backing Diameter | 16.87" |

| Cage Cone Frontface Clearance | 0.34" |

| Cage Cone Backface Clearance | 0.4" |

| Effective Center Location | 0.3" |

| Ring Material | Chrome Steel |

| Roller Material | Chrome Steel |

| Cage Material | Steel |

| Dynamic Radial Load | 199000 lbf |

| Static Radial Load | 312000 lbf |

| Dynamic Radial Rating(90 Million Revolutions)(C90) | 51700 lbf |

| Dynamic Thrust Rating(90 Million Revolutions)(Ca90) | 33400 lbf |

| Lubrication | Required |

| Temperature Range | -30° to 110 °C |

| ABEC Rating | ABEC-1 |

| Radial Clearance | Standard (Available in C3/C4/C5) |

| RoHS | Compliant |

| REACH | Compliant |

| Weight | 64 lb |

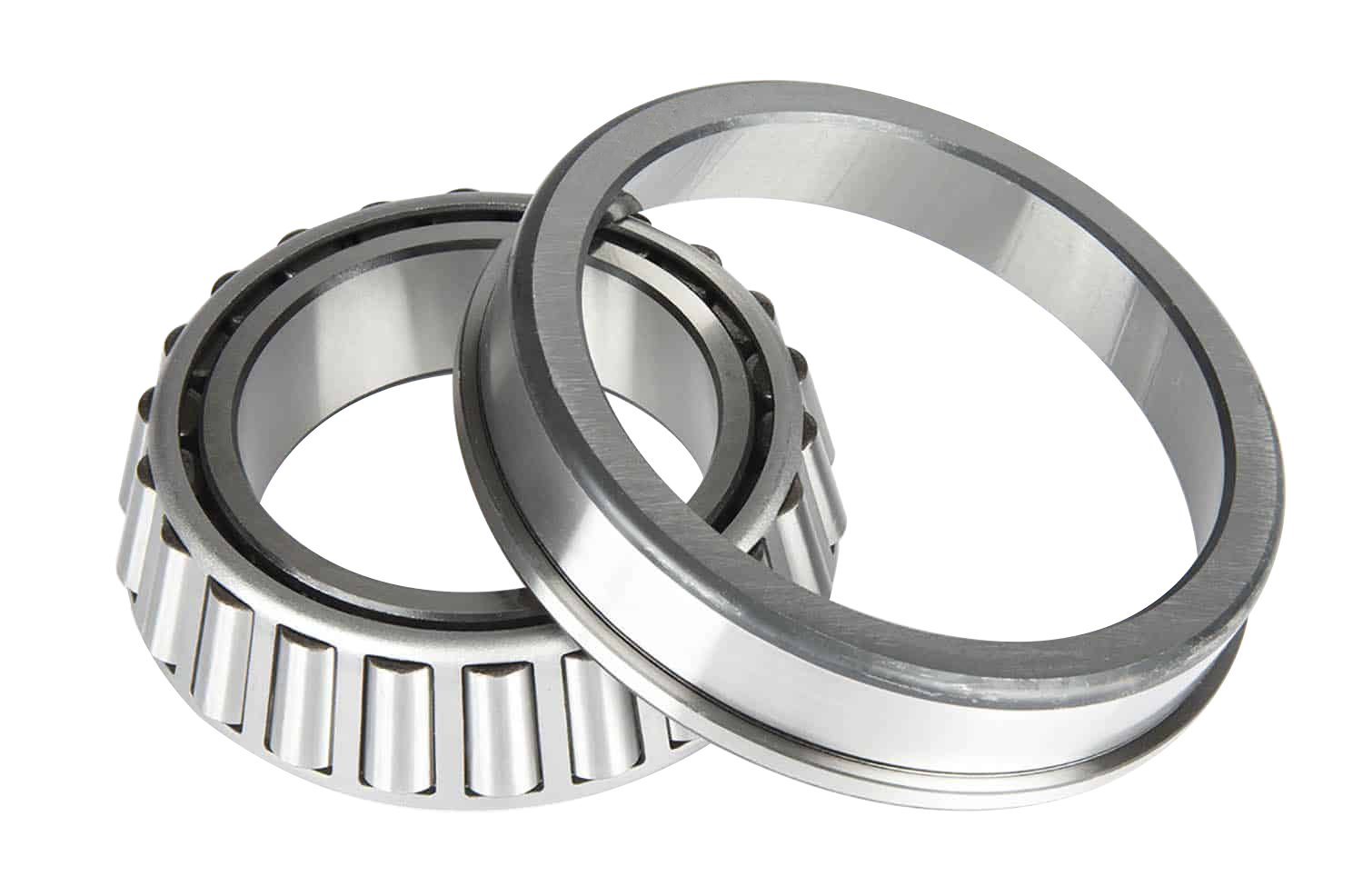

EE291201-291750-B TSF (Single Row Tapered Roller Bearings with Flange) (Imperial) consist of a tapered inner ring assembly and an outer ring. They have flanged outer rings so that the housing through-hole can be precisely aligned. EE291201-291750-B bore dia is 12". Its out dia is 17.5". EE291201-291750-B roller material is Roller_Material. Its seal type is Open. The EE291201-291750-B TSF (Single Row Tapered Roller Bearings with Flange) (Imperial) can bear both radial and axial loads with ease and provides low friction during operation even under the most severe conditions.

Typical applications include:

Gearing Systems and Transmissions, Thermal Power Coal Transporters, Port Equipment, Rubber and other Industrial applications, Machine Tool Spindles, Gear Reducer, Automotive Drive Axle, Aircraft wheels, Agricultural Wheels, Tensioning Roller, Raking Machine, Construction and Mining Equipment, Railroad Axle-box, etc.

})