DDR-830

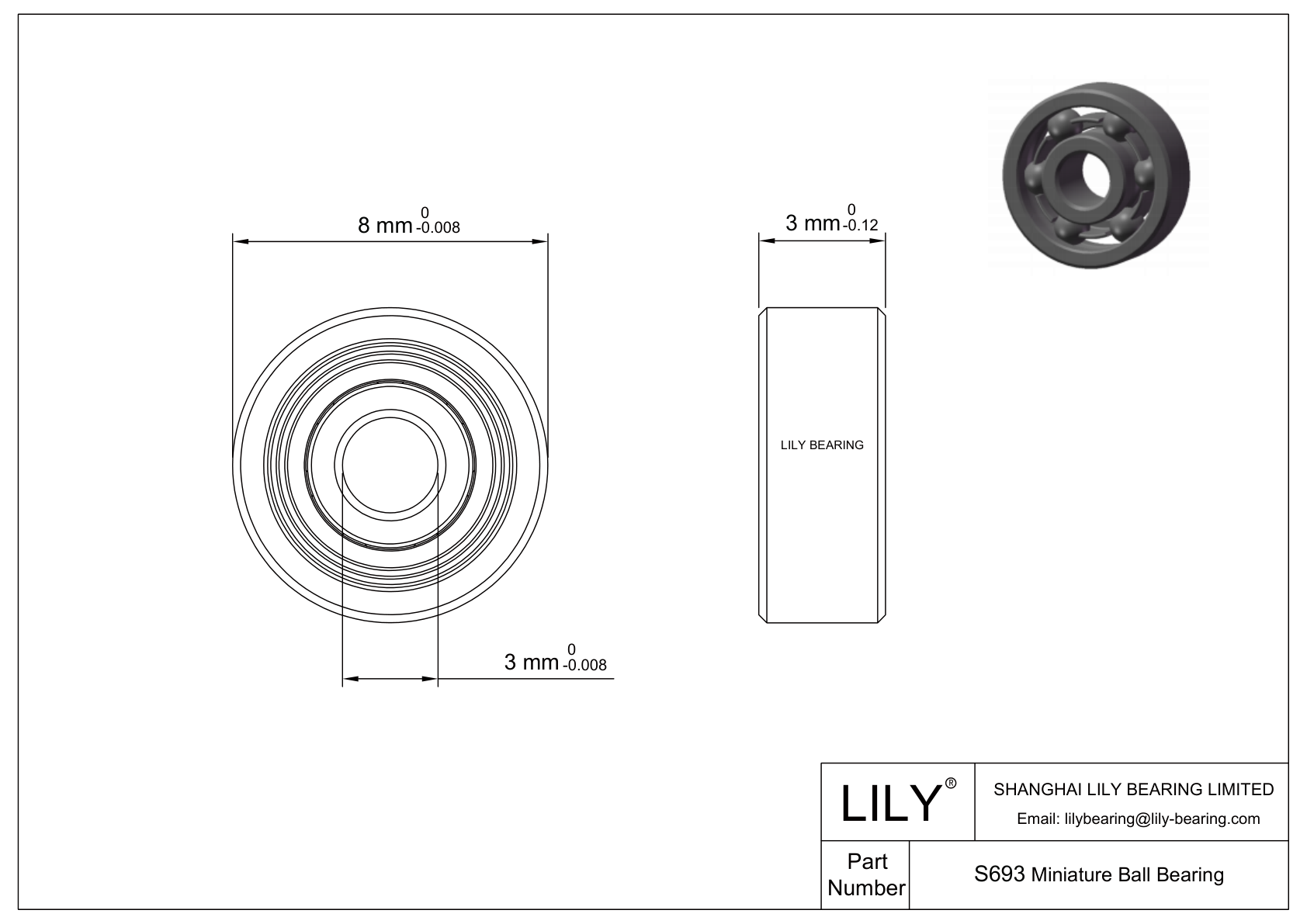

| Part Number | DDR-830 |

Brand: LILY  | |

Equivalent: NMB |

| System of Measurement | Metric |

| Bearing Type | Ball |

| For Load Direction | Radial |

| Construction | Single Row |

| Seal Type | Open |

| Bore Dia | 3 mm |

| Bore Dia Tolerance | -0.008mm to 0 |

| Outer Dia | 8 mm |

| Outer Dia Tolerance | -0.008mm to 0 |

| Width | 3 mm |

| Width Tolerance | -0.12mm to 0 |

| Ring Material | 440C Stainless Steel |

| Ball Material | 440C Stainless Steel |

| Cage Material | 300 Series Stainless Steel |

| Dynamic Radial Load | 96 lbf |

| Static Radial Load | 29 lbf |

| Max Speed (X1000 rpm) | 54 |

| Lubrication | Required |

| Temperature Range | -30° to 110 °C |

| Shaft Mount Type | Press Fit |

| ABEC Rating | ABEC1 (Available in ABEC3/5/7) |

| Radial Clearance Trade No | MC3 (Available in MC1/2/4/5/6) |

| Radial Clearance | 0.002mm to 0.013mm |

| ROHS | Compliant |

| REACH | Compliant |

| Ball Dia | 1.5880 mm |

| Ball Qty | 6 |

| Weight | 0.6 g |

DDR-830 Metric Size NMB Bearings have deep groove geometry for high speeds and supporting both radial and axial loads. These DDR-830 Metric Size NMB Bearings are for use in applications that involve combined radial and axial loads and a need for high running accuracy at high rotational speeds. For instance, DDR-830 is often used in motors, ATMs as well as Card Readers. In Food & Beverage Industry, DDR-830 is also popular. More applications about DDR-830 are as follows.

Typical Applications

Motors,Flow Meters,Medical Instruments,Vacuum Pumps,Robotics Industry,Crossbow,Food & Beverage Industry,Automation & Industry,Anemometer,ATMs & Card Readers,Galvanometers,Gas Meters,Industrial Encoders,Industrial Meters,Optical Encoders,Plastic Card Printers,Surveillance Systems,Fuel controls,Gyros, synchros and servos,Cryogenic coolers,Pulmonary assist devices,Clocks,Instrumentation,Drones and model,Fishing reel

General Selection Factors

Several factors must be considered for choosing NMB bearings. These factors include the ring material, design, shields and seals, cage, Annual Bearing Engineering Committee (ABEC) grade, radial play, and lubricant. Miniature bearings are available in open, sealed and shielded configurations. Seals and shields are used in miniature bearings (specifically ball bearings) to retain lubricants and prevent particulate contamination from reaching critical surfaces. Seals are used where minimal light contact is offered. Seals for miniature bearings provide deterrence to particulate contamination, but increase torque and limit operating speeds. Shields are used in most applications.

})