Cancel

CEZR 6222

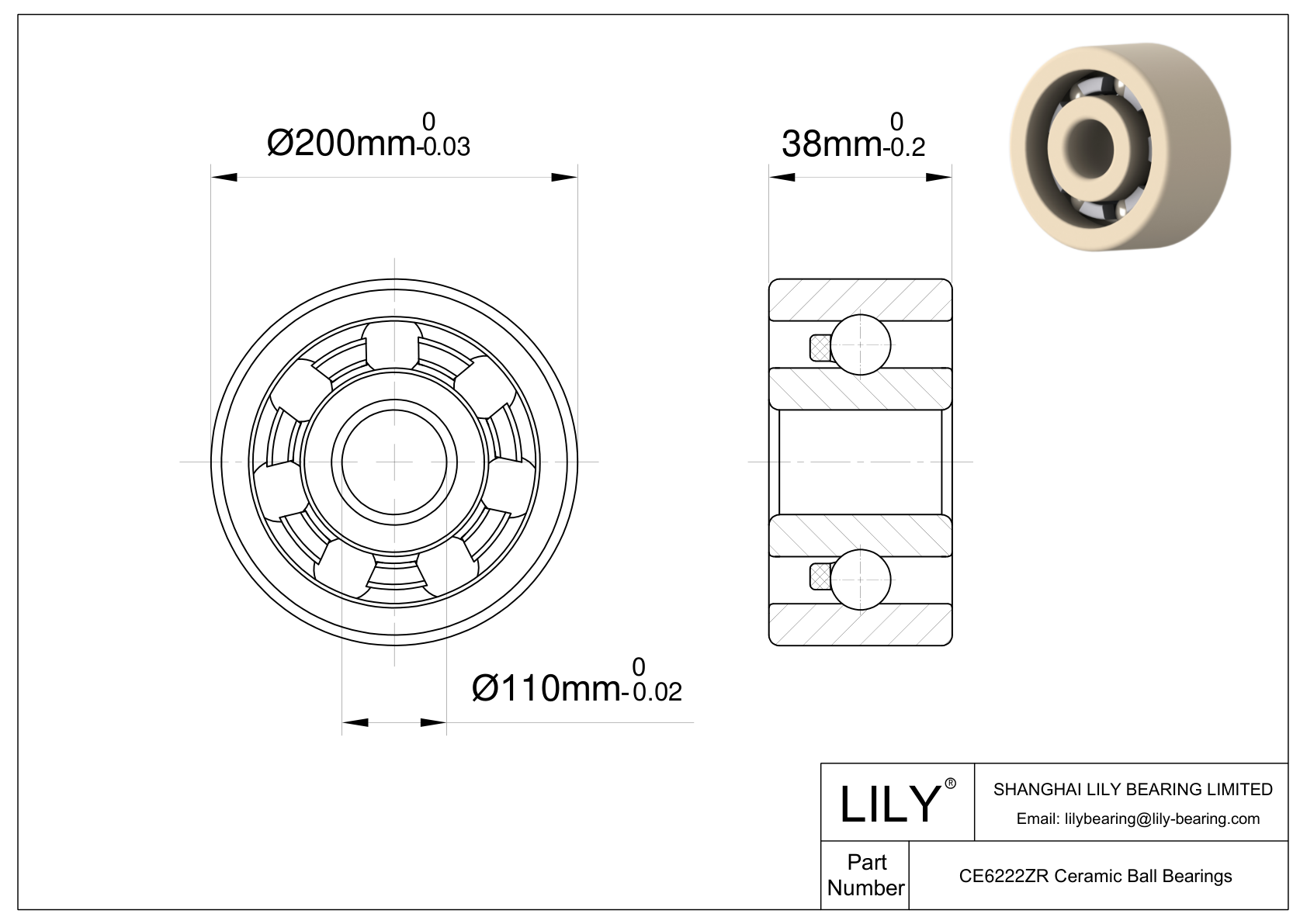

| Part Number | CEZR 6222 |

| System of Measurement | Metric |

| Bearing Type | Ball |

| For Load Direction | Radial |

| Seal Type | Open |

| Bore Dia | 110 mm |

| Outer Dia | 200 mm |

| Width | 38 mm |

| Ring Material | Zirconia |

| Balls Material | Zro2 |

| Cage Material | PEEK |

| Dynamic Radial Load | 10192 lbf |

| Static Radial Load | 7965 lbf |

| Max Speed (X1000 rpm) | 3.01 |

| Lubrication | Without |

| Temperature Range | -176 to 752 °F |

| Shoulder Diameter | 138 mm |

| Chamfer Dimension | 2.1 mm |

| Diameter Of Shaft Abutment | 122 mm |

| Diameter Of Housing Abutment | 188 mm |

| Radius Of Shaft Or Housing Fillet | 2 mm |

| Fatigue Load Limit | 4 kN |

| Reference Speed | 6700 r/min |

| Minimum Load Factor | 0.025 |

| Calculation Factor | 14.3 |

| Recess Diameter | 176.7 mm |

| Weight | 3337.50 g |

Design Features of CEZR 6222 Bearing

CEZR 6222 Bearing is a ball bearing that utilizes balls made from zirconia (zirconium dioxide - ZrO₂) ceramic as the rolling element. CEZR 6222 bore dia is 110 mm. Its out dia is 200 mm. CEZR 6222 width is 38 mm. Its ability to operate under high-speed conditions, coupled with its resistance to various challenging environments, makes it the go-to choice for professionals seeking both durability and precision. This bearing stands outs as a quintessential blend of precision engineering and material science.

What Benefits Can CEZR 6222 Bearing Provide?

- Low Friction: It inherently has a lower coefficient of friction compared to traditional steel ball bearings.

- Wear Resistance: Zirconia's hardness gives this bearing superior wear resistance, prolonging its service life.

- Non-Conductive: CEZR 6222 bearing is electrically non-conductive, making it suitable for applications where electrical insulation is crucial.

- Thermal Stability: Zirconia ceramic retains its properties over a wide range of temperatures and showcases excellent thermal stability.

- Corrosion Resistance: The ceramic material is resistant to various corrosive agents, making this bearing ideal for hostile environments.

What Can CEZR 6222 Bearing Be Used for?

CEZR 6222 Bearing excels in unique applications due to its specific properties:

- High-Temperature Environments: such as furnace conveyor systems or aerospace applications.

- Corrosive Settings: such as equipment in chemical processing plants or marine applications.

- Electrical Insulation: such as Electric motors or generators.

- Cleanroom Operations: such as Semiconductor manufacturing or pharmaceutical production units.

- High-Speed Tools and Devices: such as dental drills or precision spindles operating at elevated RPMs.

Recommended Products