Cancel

CESC RLS4

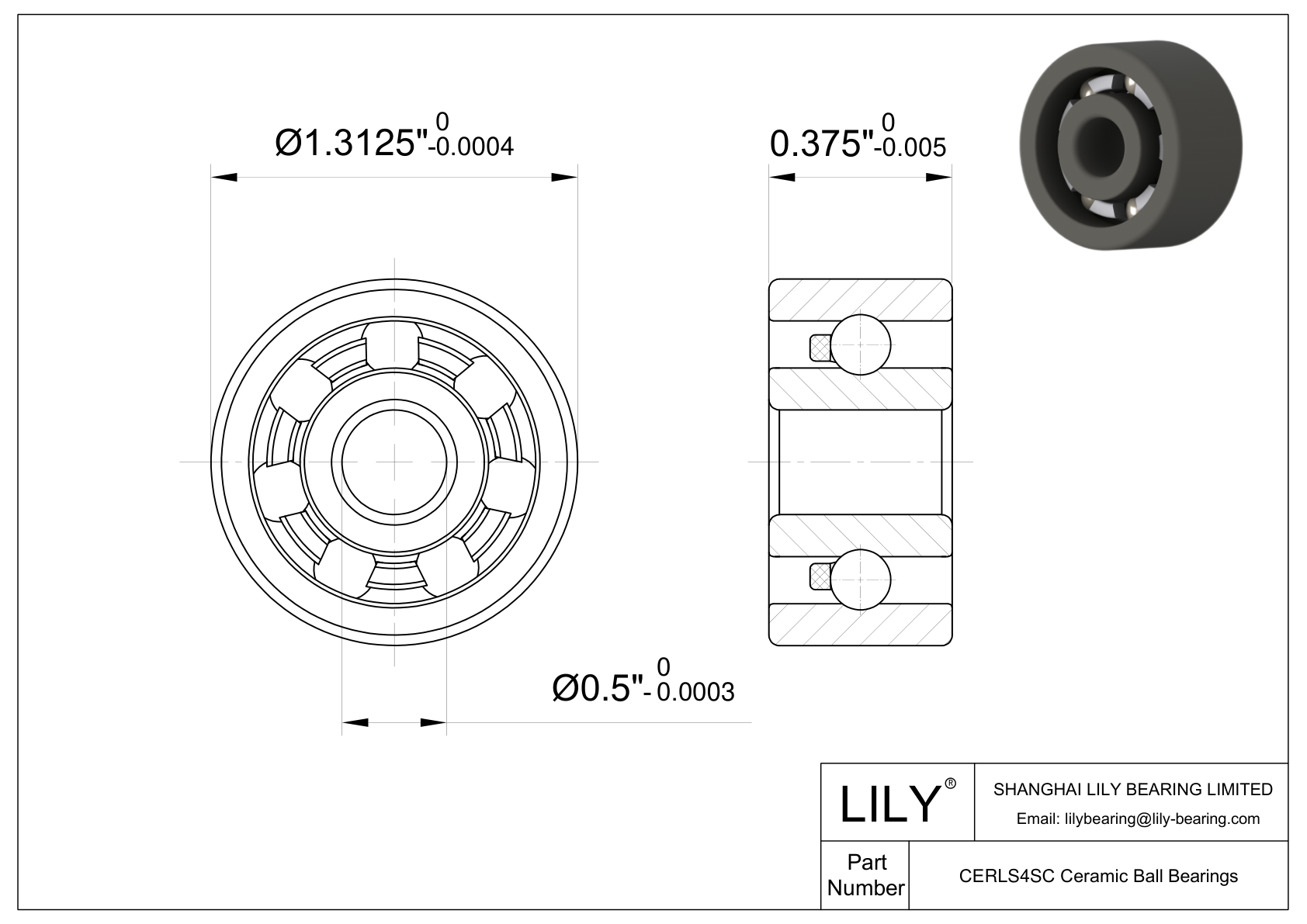

| Part Number | CESC RLS4 |

| System of Measurement | Inch |

| Bearing Type | Ball |

| For Load Direction | Radial |

| Construction | Single Row |

| Seal Type | Open |

| Bore Dia | 0.5" |

| Bore Dia Tolerance | -0.0003" to 0" |

| Outer Dia | 1.3125" |

| Outer Dia Tolerance | -0.0004" to 0" |

| Width | 0.375" |

| Width Tolerance | -0.005" to 0" |

| Ring Material | Silicon Carbide |

| Balls Material | Sic |

| Cage Material | PEEK |

| Dynamic Radial Load | 327 lbf |

| Static Radial Load | 139 lbf |

| Max Speed (X1000 rpm) | 22.4 |

| Lubrication | Without |

| Shaft Mount Type | Press Fit |

| ABEC Rating | ABEC-1 |

| Radial Clearance Trade No | C0 |

| Radial Clearance | 0.00008" to 0.00071" |

| Temperature Range | -176 to 2192 °F |

| RoHS | Compliant |

| Weight | 16.00 g |

Design Features of CESC RLS4 Bearing

CESC RLS4 Bearing is a specific type of ball bearing designed and manufactured with precision dimensions measured in inches. It is constructed with silicon carbide, an advanced ceramic material. CESC RLS4 bore dia is 0.5". Its out dia is 1.3125". CESC RLS4 width is 0.375". This Bearing offers superior properties suited for a variety of demanding applications. This bearing, made from advanced silicon carbide materials, is resistant to corrosion, wear, and high temperatures. Ideal for specialized industries, they provide long-lasting performance and reduced maintenance needs.

What Benefits Can CESC RLS4 Bearing Provide?

- High-Temperature Tolerance: CESC RLS4 Bearing reliably operates in extreme temperatures, exceeding 1,500°C.

- Chemical Resistance: This bearing withstands most corrosive chemicals, ensuring durability in aggressive conditions.

- Low Friction Coefficient: Its minimized friction promotes smoother operations and extended bearing longevity.

- Wear Resistance: Owing to SiC's inherent hardness, CESC RLS4 Bearing exhibits superior wear resistance.

- Stiffness and Strength: This bearing provides exceptional stiffness and strength, making it optimal for handling heavy loads.

What Can CESC RLS4 Bearing Be Used for?

CESC RLS4 Bearing excels in unique applications due to its specific properties:

- Chemical Processing: Its resistance to most corrosive chemicals makes it suitable for use in chemical pumps, reactors, and other equipment exposed to aggressive substances.

- High-Temperature Furnaces: Owing to its ability to operate at temperatures exceeding 1,500°C, CESC RLS4 Bearing is ideal for use in metallurgical and heat treatment furnaces.

- Semiconductor Manufacturing: The semi-conductive properties of SiC makes CESC RLS4 Bearing a preferred choice in semiconductor production equipment and machinery.

- Medical Devices: Its biocompatibility allows it to be employed in certain medical equipment without causing adverse reactions.

})