Cancel

CEF2-6ZR

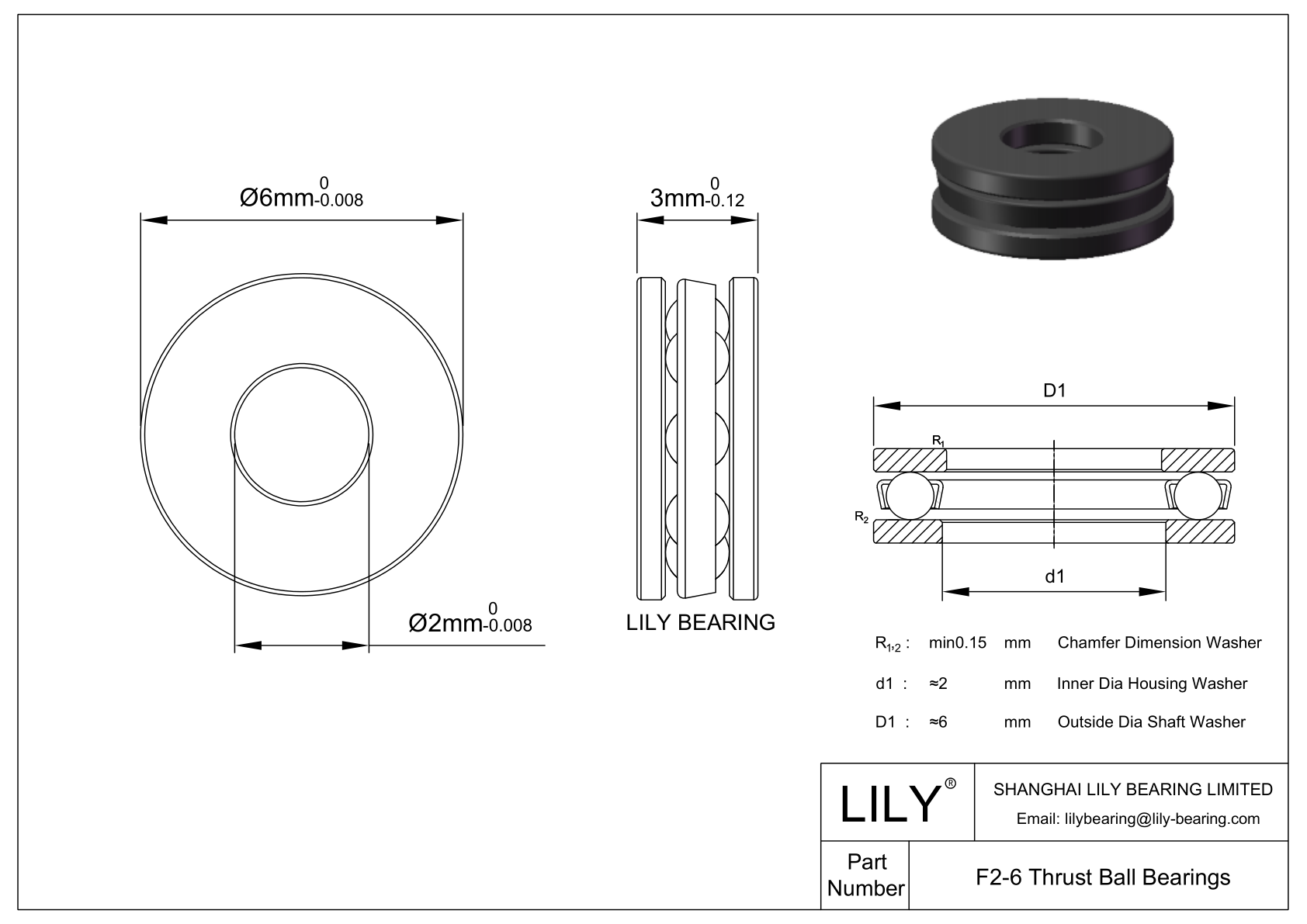

| Part Number | CEF2-6ZR |

| System of Measurement | Metric |

| Bearing Type | Ball |

| Washers Type | flat raceway |

| For Load Direction | Thrust |

| Construction | Single Direction |

| Bore Dia | 2 mm |

| Bore Dia Tolerance | -0.008mm to 0 |

| Outer Dia | 6 mm |

| Outer Dia Tolerance | -0.008mm to 0 |

| Housing Washer ID | 2 mm |

| Shaft Washer OD | 6 mm |

| Height | 3 mm |

| Height Tolerance | -0.12mm to 0 |

| Washer Material | Zirconia |

| Balls Material | Zro2 |

| Cage Material | PEEK |

| Dynamic Axial Load | 9 lbf |

| Static Axial Load | 4 lbf |

| Max Speed (X1000 rpm) | 11.2 |

| Lubrication | Required |

| Temperature Range | -176 to 752 °F |

| RoHS | Compliant |

| REACH | Compliant |

| Ball Dia | 1 mm |

| Ball Qty | 6 |

| Weight | 0 kg |

Design Features of CEF2-6ZR Bearing

CEF2-6ZR Bearing is a high-end, precision-engineered solution for various demanding applications, offering unique advantages due to its advanced material properties. CEF2-6ZR bore dia is 2 mm. Its out dia is 6 mm. CEF2-6ZR height is 3 mm. This bearing is particularly valuable in situations demanding a combination of high strength, temperature resistance, and minimal weight.

What Benefits Can CEF2-6ZR Bearing Provide?

- High Wear Resistance: Its Zirconia composition ensures exceptional durability, making this bearing resistant to wear and tear even in abrasive environments.

- Corrosion Resistance: This bearing is highly resistant to a range of chemicals, ideal for use in corrosive settings, extending their lifespan.

- High-Temperature Tolerance: Capable of maintaining performance under high temperatures, suitable for applications with thermal exposure.

- Low Friction Coefficient: The inherent low friction of Zirconia minimizes energy loss and wear, improving operational efficiency, especially in high-speed applications.

What Can CEF2-6ZR Bearing Be Used for?

CEF2-6ZR Bearing is highly versatile and can be employed in a variety of applications due to their unique properties. Key uses include:

- Aerospace Applications: Their lightweight yet strong nature makes them ideal for aerospace components, where reducing weight while maintaining durability is crucial.

- Chemical Processing Industry: The excellent corrosion resistance of Zirconia bearings is beneficial in environments with corrosive chemicals, enhancing longevity and reliability in chemical processing equipment.

- High-Performance Automotive: In automotive engineering, especially in high-performance and luxury vehicles, these bearings contribute to enhanced efficiency and handling due to their reduced weight and high wear resistance.

- Medical Equipment: The biocompatibility of Zirconia makes these bearings suitable for various medical devices, where sterility and non-reactivity are essential.

- High-Speed Machinery: Their ability to maintain integrity at high rotational speeds and resist thermal degradation makes them suitable for high-speed applications, such as in turbines, centrifugal machines, and high-speed spindles.

- Advanced Robotics and Precision Instruments: In robotics and precision instruments, these bearings offer the necessary reliability and precision, especially in applications requiring accurate motion control.

Recommended Products

})