Cancel

CE7264ZR

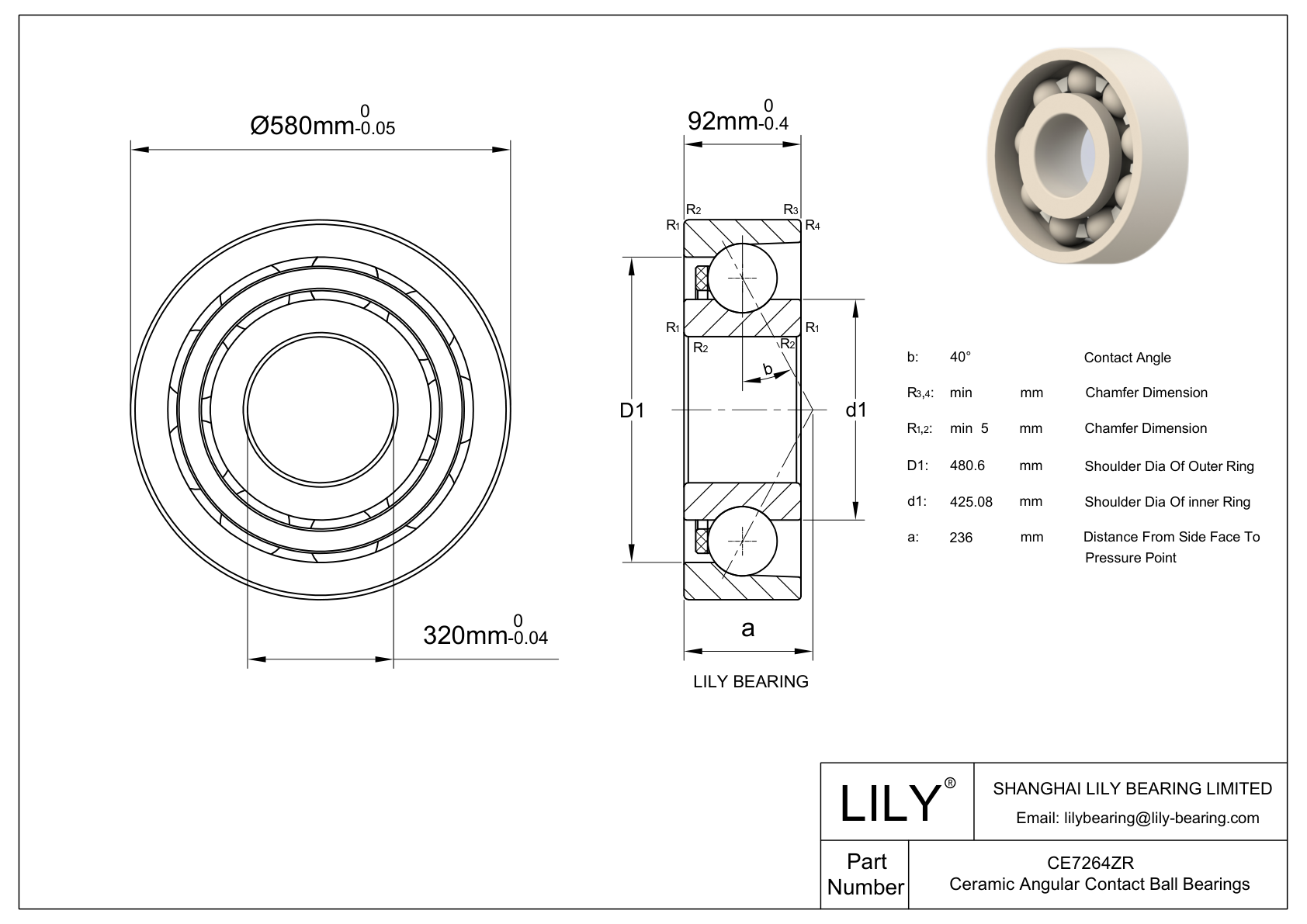

| Part Number | CE7264ZR |

| System of Measurement | Metric |

| Bearing Type | Ball |

| Contact Angle | 40° |

| For Load Direction | Angular Contact |

| Construction | Single Row |

| Seal Type | Open |

| Bore Dia | 320 mm |

| Bore Dia Tolerance | -0.04 mm to 0 |

| Outer Dia | 580 mm |

| Outer Dia Tolerance | -0.05 mm to 0 |

| Width | 92 mm |

| Width Tolerance | -0.4 mm to 0 |

| Shoulder Diameter Inner Ring (Large Side Face)(d1) | 425.08 mm |

| Shoulder Diameter Inner Ring (Small Side Face)(d2) | 383.79 mm |

| Shoulder Diameter Outer Ring (Large Side Face)(D1) | 480.6 mm |

| Chamfer Dimension (r1 2)(min) | 5 mm |

| Distance Pressure Point (a) | 236 mm |

| Ring Material | Zirconia |

| Balls Material | Zro2 |

| Cage Material | PEEK |

| Dynamic Radial Load | 34720 lbf |

| Static Radial Load | 61912 lbf |

| Max Speed (X1000 rpm) | 0.84 |

| Lubrication | Dry |

| Temperature Range | -176 to 752 °F |

| ABEC Rating | ABEC-1 |

| ROHS | Compliant |

| REACH | Compliant |

| Weight | 82.5 kg |

Design Features of CE7264ZR Bearing

CE7264ZR Bearing has a single row of balls placed in a way that the contact angle between the balls and the raceway is optimized for handling combined axial and radial loads. Balls in this Bearing are made from zirconia (ZrO2), a ceramic material known for its exceptional strength and resistance to wear and corrosion. CE7264ZR bore dia is 320 mm. Its out dia is 580 mm. CE7264ZR width is 92 mm. It is designed for applications that demand high precision and speed.

What Benefits Can CE7264ZR Bearing Provide?

- High Precision and Speed: Optimized for high-speed applications requiring precise motion control.

- Strength and Durability: Zirconia offers excellent wear resistance, enhancing bearing longevity.

- Corrosion Resistance: Highly resistant to corrosion, suitable for harsh chemical environments.

- Thermal Stability: Maintains performance across a wide temperature range.

- Electrical Insulation: Non-conductive nature provides essential electrical insulation in sensitive applications.

What Can CE7264ZR Bearing Be Used for?

CE7264ZR Bearing is suitable for applications such as:

- High-Speed Spindle Machinery: Ideal in CNC machines and high-speed milling applications due to their precision and speed capabilities.

- Precision Tools and Instruments: Used in equipment requiring meticulous accuracy, such as precision measuring devices and high-speed drills.

- Industrial Equipment in Aggressive Environments: Suitable for machinery exposed to corrosive chemicals or extreme conditions, ensuring durability and reliability.

- Advanced Medical Devices and Equipment: Utilized in medical imaging devices and surgical tools, where high precision, reliability, and resistance to sterilization processes are critical.