Cancel

CE70/950ZRPP

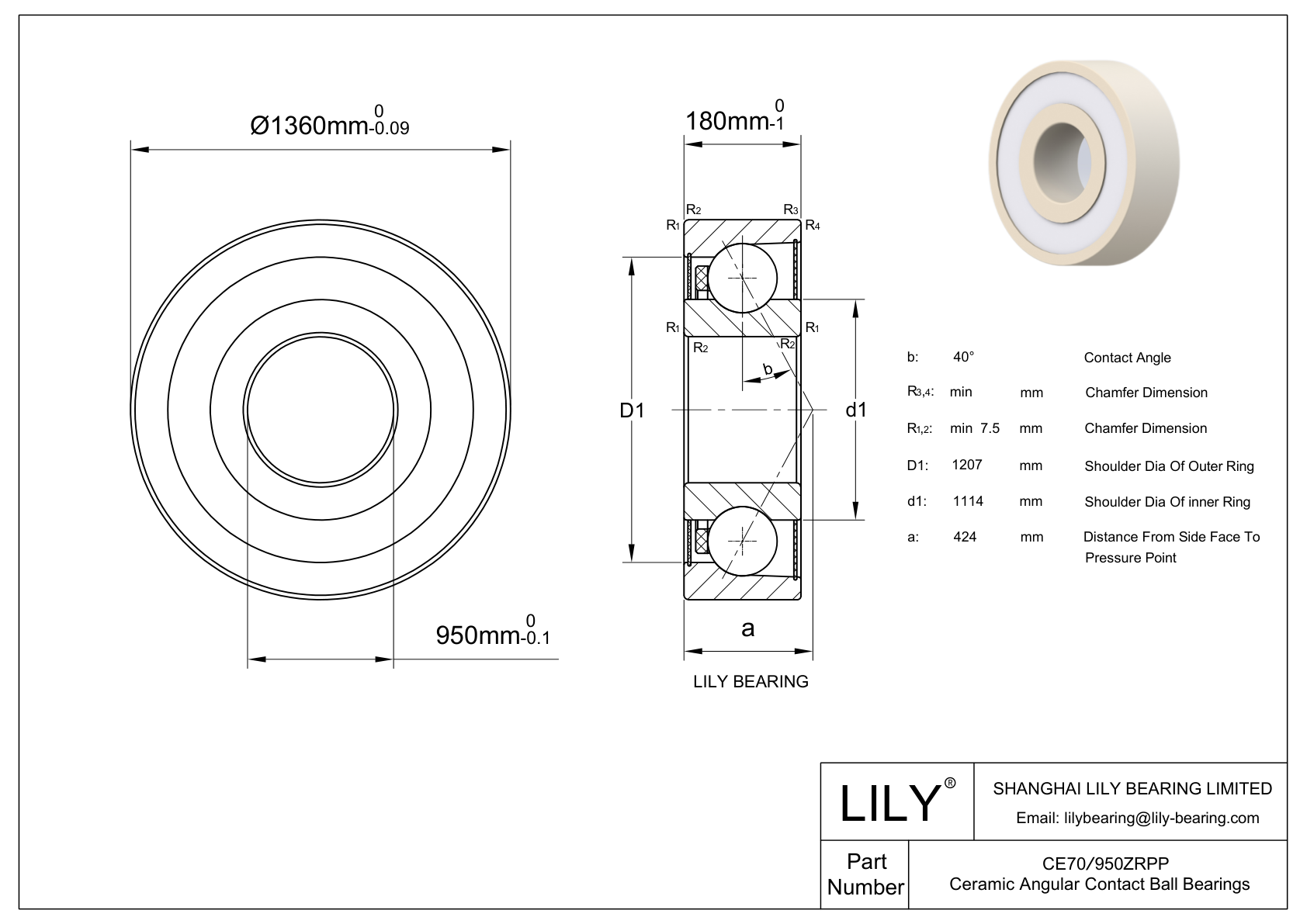

| Part Number | CE70/950ZRPP |

| System of Measurement | Metric |

| Bearing Type | Ball |

| Contact Angle | 40° |

| For Load Direction | Angular Contact |

| Construction | Single Row |

| Seal Type | Sealed |

| Bore Dia | 950 mm |

| Bore Dia Tolerance | -0.1 mm to 0 |

| Outer Dia | 1360 mm |

| Outer Dia Tolerance | -0.09mm to 0 |

| Width | 180 mm |

| Width Tolerance | -1 mm to 0 |

| Shoulder Diameter Inner Ring (Large Side Face)(d1) | 1114 mm |

| Shoulder Diameter Inner Ring (Small Side Face)(d2) | 1043 mm |

| Shoulder Diameter Outer Ring (Large Side Face)(D1) | 1207 mm |

| Chamfer Dimension (r1 2)(min) | 7.5 mm |

| Distance Pressure Point (a) | 424 mm |

| Ring Material | Zirconia |

| Balls Material | Zro2 |

| Cage Material | PEEK |

| Dynamic Radial Load | 98938 lbf |

| Static Radial Load | 315632 lbf |

| Max Speed (X1000 rpm) | 0.28 |

| Lubrication | Dry |

| Temperature Range | -176 to 752 °F |

| ABEC Rating | ABEC-1 |

| ROHS | Compliant |

| REACH | Compliant |

| Weight | 603.75 kg |

Design Features of CE70/950ZRPP Bearing

CE70/950ZRPP Bearing has a single row of balls placed in a way that the contact angle between the balls and the raceway is optimized for handling combined axial and radial loads. Balls in this Bearing are made from zirconia (ZrO2), a ceramic material known for its exceptional strength and resistance to wear and corrosion. CE70/950ZRPP bore dia is 950 mm. Its out dia is 1360 mm. CE70/950ZRPP width is 180 mm. It is designed for applications that demand high precision and speed.

What Benefits Can CE70/950ZRPP Bearing Provide?

- High Precision and Speed: Optimized for high-speed applications requiring precise motion control.

- Strength and Durability: Zirconia offers excellent wear resistance, enhancing bearing longevity.

- Corrosion Resistance: Highly resistant to corrosion, suitable for harsh chemical environments.

- Thermal Stability: Maintains performance across a wide temperature range.

- Electrical Insulation: Non-conductive nature provides essential electrical insulation in sensitive applications.

What Can CE70/950ZRPP Bearing Be Used for?

CE70/950ZRPP Bearing is suitable for applications such as:

- High-Speed Spindle Machinery: Ideal in CNC machines and high-speed milling applications due to their precision and speed capabilities.

- Precision Tools and Instruments: Used in equipment requiring meticulous accuracy, such as precision measuring devices and high-speed drills.

- Industrial Equipment in Aggressive Environments: Suitable for machinery exposed to corrosive chemicals or extreme conditions, ensuring durability and reliability.

- Advanced Medical Devices and Equipment: Utilized in medical imaging devices and surgical tools, where high precision, reliability, and resistance to sterilization processes are critical.

Recommended Products