Cancel

CE51210SC

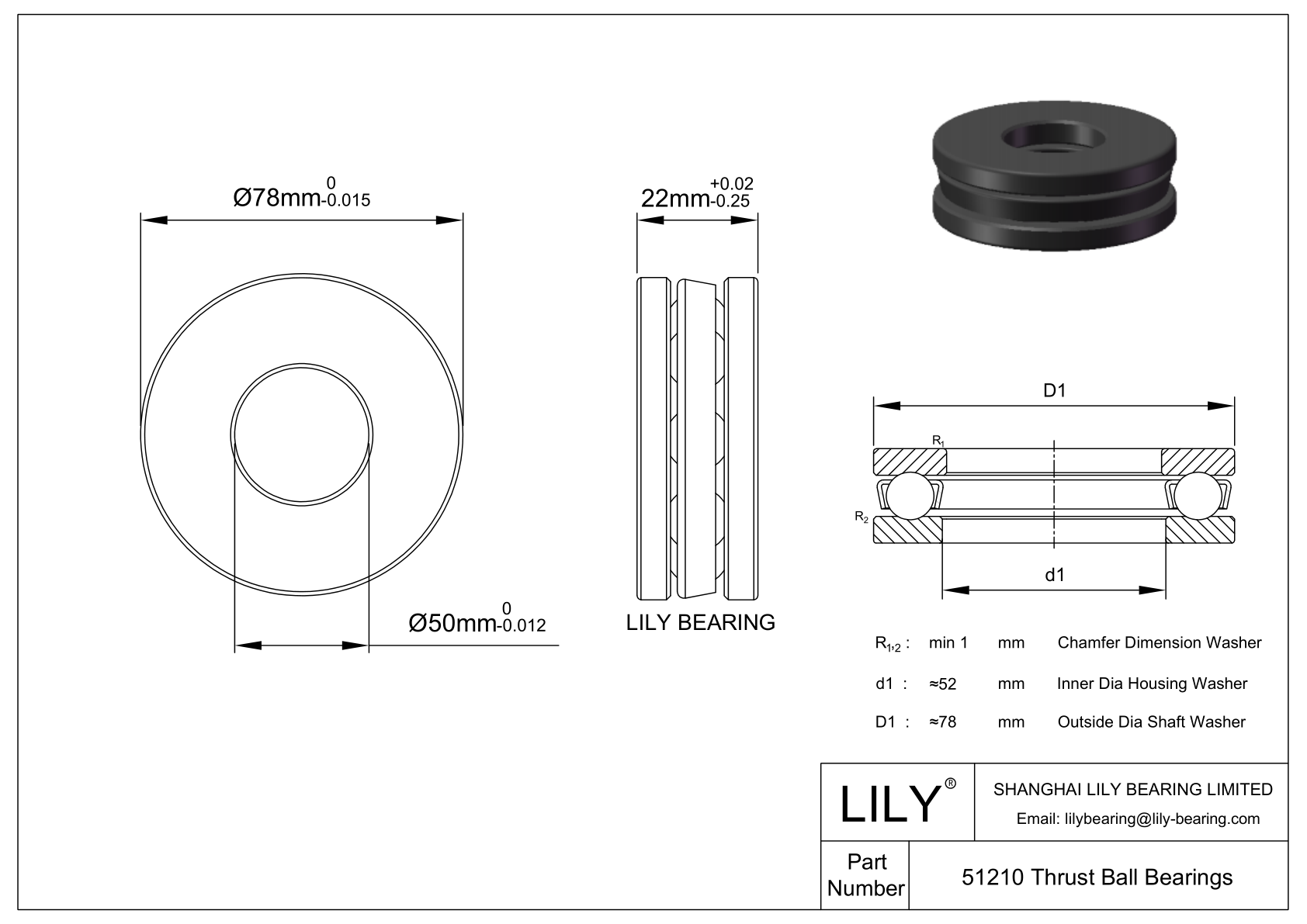

| Part Number | CE51210SC |

| System of Measurement | Metric |

| Bearing Type | Ball |

| For Load Direction | Thrust |

| Construction | Single Direction |

| Bore Dia | 50 mm |

| Bore Dia Tolerance | -0.012mm to 0 |

| Outer Dia | 78 mm |

| Outer Dia Tolerance | -0.015mm to 0 |

| Outside Dia Shaft Washer | 78 mm |

| Height | 22 mm |

| Height Tolerance | +0.02mm to -0.25mm |

| Chamfer Dimension Washer | 1 mm |

| Inner Dia Housing Washer | 52 mm |

| Washer Material | Silicon Carbide |

| Balls Material | Sic |

| Cage Material | PEEK |

| Dynamic Axial Load | 2221 lbf |

| Static Axial Load | 5216 lbf |

| Max Speed (X1000 rpm) | 3.15 |

| Temperature Range | -176 to 2192 °F |

| RoHS | Compliant |

| REACH | Compliant |

| Weight | 0.148 kg |

Design Features of CE51210SC Bearing

CE51210SC Bearing is a specialized type of bearing designed to provide superior performance in challenging environments, using the advanced properties of Silicon Carbide (SiC). CE51210SC bore dia is 50 mm. Its out dia is 78 mm. CE51210SC height is 22 mm. This bearing offers a combination of hardness, thermal stability, chemical resistance, and versatility that is unmatched by traditional bearing materials.

What Benefits Can CE51210SC Bearing Provide?

- Exceptional Wear Resistance: Its extreme hardness ensures outstanding durability and longevity, even in abrasive conditions.

- High Thermal Stability: Excellent performance at high temperatures, maintaining integrity and functionality in thermal extremes.

- Chemical and Corrosion Resistance: Resistant to a wide array of chemicals, making this bearing suitable for harsh industrial environments.

- High-Speed Capability: Its design ensures stable, efficient performance at high speeds, ideal for precision machinery and high-speed applications.

- High Load Capacity: Its robustness enables this bearing to handle high load capacities, essential in heavy-duty industrial applications.

What Can CE51210SC Bearing Be Used for?

CE51210SC Bearing is suited for a variety of professional and industrial applications, such as:

- Industrial Machinery: In high-speed machinery and equipment, such as turbines and compressors, due to its high-speed capability and thermal stability.

- Semiconductor Manufacturing: Where precision and resistance to harsh chemicals are necessary, making this bearing suitable for fabrication equipment.

- Energy Sector: In applications like power generation equipment, where durability under high temperature and corrosive conditions is essential.

- Aerospace Industry: For components in aircraft and spacecraft, where high strength, low weight, and thermal stability are critical.