Cancel

CE1211SC

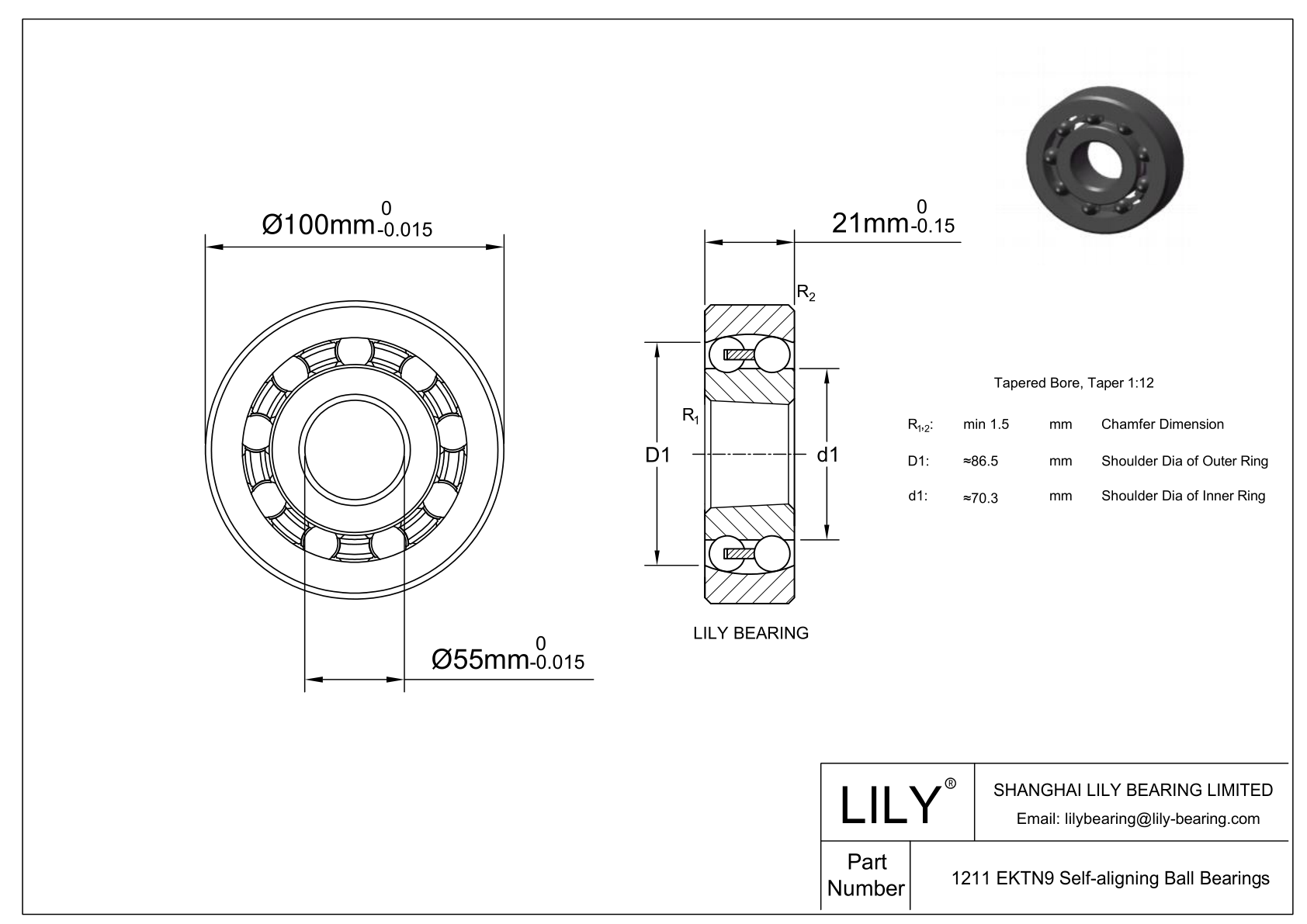

| Part Number | CE1211SC |

| System of Measurement | Metric |

| Bearing Type | Ball |

| For Load Direction | Radial |

| Construction | Double Row |

| Seal Type | Open |

| Bore Dia | 55 mm |

| Bore Dia Tolerance | -0.015mm to 0 |

| Outer Dia | 100 mm |

| Outer Dia Tolerance | -0.015mm to 0 |

| Width | 21 mm |

| Width Tolerance | -0.15mm to 0 |

| Shoulder Dia Of Inner Ring | 70.3 mm |

| Shoulder Dia Of Outer Ring | 86.5 mm |

| Chamfer Dimension | 1.5 mm |

| Ring Material | Silicon Carbide |

| Balls Material | Sic |

| Cage Material | PEEK |

| Dynamic Radial Load | 1242 lbf |

| Static Radial Load | 477 lbf |

| Max Speed (X1000 rpm) | 6.3 |

| Lubrication | Lubricated |

| Temperature Range | -176 to 2192 °F |

| ROHS | Compliant |

| REACH | Compliant |

| Weight | 0.284 kg |

Design Features of CE1211SC Bearing

CE1211SC Bearing, made from Silicon Carbide (SiC), is a type of ball bearing specifically designed to manage misalignment and shaft deflections while maintaining high performance. Its bore dia is 55 mm. Its out dia is 100 mm. CE1211SC width is 21 mm. It is used in applications where high precision, durability, and resistance to extreme conditions are required

What Benefits CE1211SC Bearings Provide?

- High Wear Resistance: Exceptional hardness of Silicon Carbide provides superior resistance to wear and abrasion, enhancing lifespan even under tough conditions.

- Thermal Stability: This bearing reliably performs in high-temperature environments, suitable for thermally demanding applications.

- Corrosion Resistance: Chemically inert, CE1211SC bearing can withstand corrosion in aggressive chemical settings, improving durability.

- Self-Aligning Feature: Ability to accommodate shaft misalignments reduces stress, preventing premature failure and extending service life, particularly in misalignment-prone systems.

- Low Friction Coefficient: The material properties of Silicon Carbide ensure low friction, boosting energy efficiency and reducing wear in high-speed operations.

- Electrical Insulation: Non-conductive nature makes them ideal for electrical and electronic applications, ensuring insulation and safety.

What Can CE1211SC Bearing Be Used for?

CE1211SC Bearing is suited for a variety of professional and industrial applications, such as:

- High-Speed Machinery: Ideal for machinery that operates at high speeds due to their low friction and thermal stability, such as in turbines and high-speed spindles.

- Aerospace Industry: Their lightweight and high-temperature resistant properties make them well-suited for aerospace applications, where efficiency and reliability under extreme conditions are crucial.

- Chemical Processing Equipment: The chemical inertness and corrosion resistance of Silicon Carbide bearings are beneficial in environments exposed to corrosive substances, like chemical processing plants.

- Electric Motors and Generators: Their electrical insulation properties make them suitable for use in electric motors and generators, where preventing electrical current transfer is essential.

})