Cancel

6706 AL203 FC LD

Price $ 51.92

Number

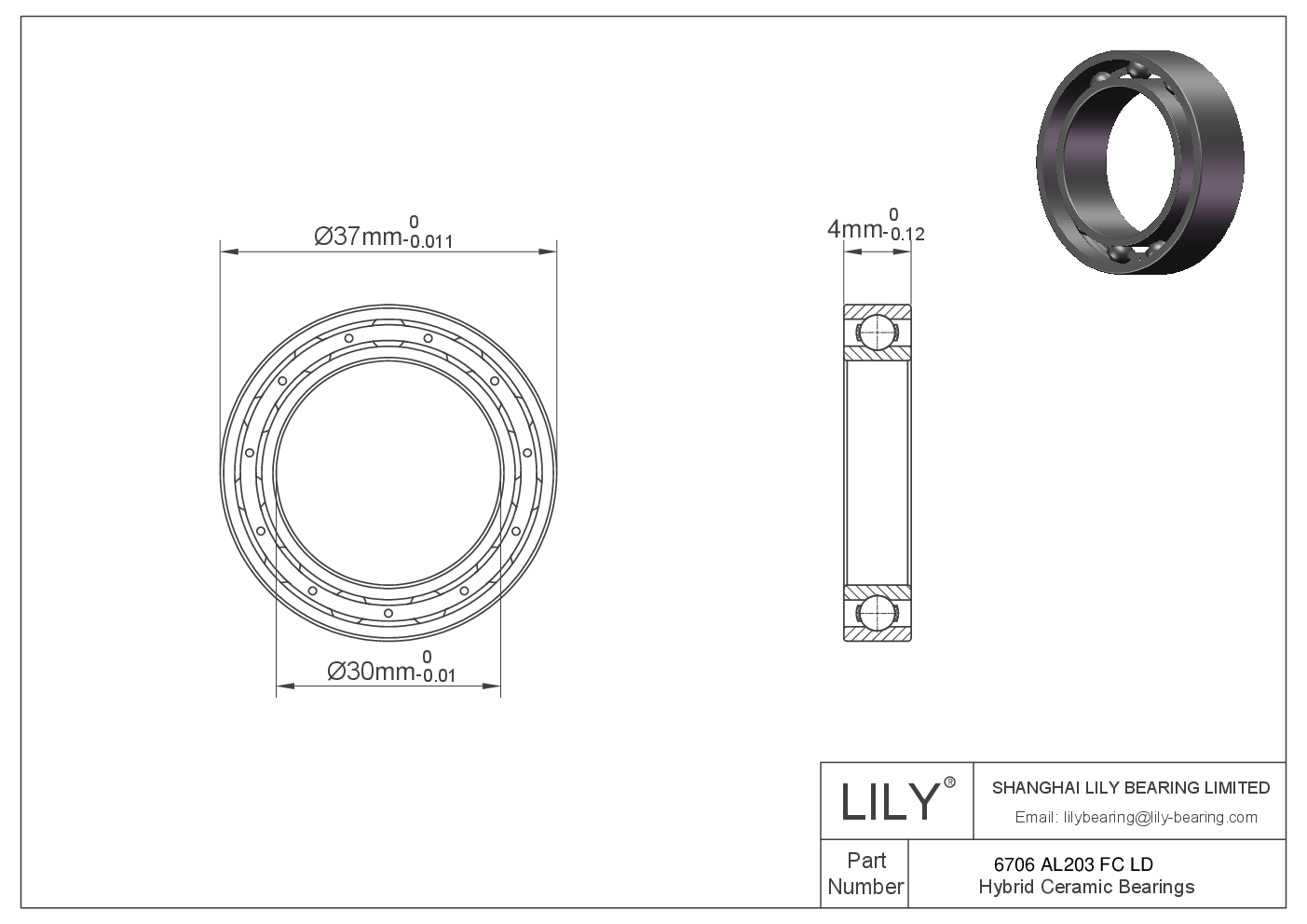

| Part Number | 6706 AL203 FC LD |

| System of Measurement | Metric |

| Bearing Type | Ball |

| For Load Direction | Radial |

| Construction | Single Row |

| Inner Ring Type | Standard |

| Seal Type | Open |

| Bore Dia | 30 mm |

| Bore Dia Tolerance | -0.01mm to 0 |

| Outer Dia | 37 mm |

| Outer Dia Tolerance | -0.011mm to 0 |

| Width | 4 mm |

| Width Tolerance | -0.12mm to 0 |

| Ring Material | Chrome Steel |

| Cage Material | Stainless Steel |

| Lubrication | Ld Lube Dry |

| Shaft Mount Type | Press Fit |

| Temperature Range | -86 to 230 °F |

| ABEC Rating | Abec#1/isop0 |

| Radial Clearance Trade No | MC3 |

| Ball Grade | 5 |

| RoHS | Compliant |

| REACH | Compliant |

Design Features of 6706 AL203 FC LD Bearing

6706 AL203 FC LD Bearing utilizes ceramic balls, typically made of silicon nitride (Si3N4), combined with steel inner and outer races. 6706 AL203 FC LD bore dia is 30 mm. Its out dia is 37 mm. 6706 AL203 FC LD width is 4 mm. This Bearing provides a sophisticated, high-performance solution that caters to the unique challenges presented by modern industrial and technological applications.

What Benefits Can 6706 AL203 FC LD Bearing Provide?

- Reduced Friction: Ceramic's low frictional properties ensure smoother operation and decreased heat generation.

- Enhanced Durability: The wear-resistant nature of ceramic extends the bearing's lifespan, particularly in demanding conditions.

- Corrosion Resistance: Ceramic balls resist moisture and chemicals, safeguarding the bearing from corrosive environments.

- Electrical Insulation: Its non-conductive composition prevents electrical arcing, essential in electrically active setups.

- High-Speed Operation: Its attributes permit this bearing to operate efficiently at elevated rotational speeds.

What Can 6706 AL203 FC LD Bearing Be Used for?

6706 AL203 FC LD Bearing is employed in various applications due to its unique characteristics. It can be used for:

- Electric Motors: Ideal for preventing electrical arcing, especially in electric vehicles.

- Precision Machinery: Suited for high rotational accuracy needs.

- Aerospace: Meeting the demands of wear resistance and thermal stability.

- High-Frequency Machining: Beneficial for high-speed spindles and machining centers.

- Harsh Environments: Resisting corrosion and withstanding extreme temperatures.

Recommended Products

})