- Equivalent to Manufacturer :

- AMI

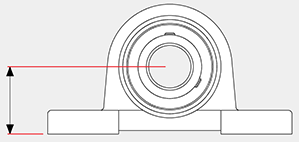

Mounted Bearing Units Pillow Block Bearing Units

1143 ProductsPillow Block Bearing Units are essential components in various mechanical systems. These units consist of an insert bearing mounted in a housing, which can be securely bolted to a support surface. They are designed to provide support for a rotating shaft.

Types of Pillow Block Bearing Units

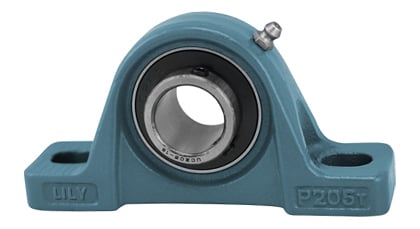

Set Screw Locking

- Design: Incorporates set screws that secure the bearing to the shaft.

- Applications: Ideal for applications where the shaft undergoes little or no axial load.

- Advantages: Simple design, easy to install and maintain.

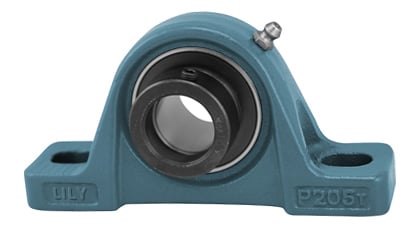

Eccentric Collar Locking

- Design: Features an eccentric collar that grips the shaft when rotated.

- Applications: Suitable for applications with moderate axial loads and vibrations.

- Advantages: Provides a more secure grip on the shaft than set screw locking.

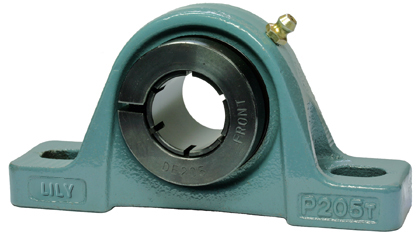

Accu-Loc Concentric Collar Locking

- Design: Utilizes a concentric collar that evenly grips around the shaft, reducing stress points.

- Applications: Best for applications requiring high precision and reduced vibration.

- Advantages: Even distribution of clamping forces, providing a balanced and secure fit.

Adapter Sleeve Locking

- Design: Employs an adapter sleeve to secure the bearing to the shaft.

- Applications: Ideal for high-speed applications and those involving significant vibration or impact loads.

- Advantages: Allows for easy mounting and dismounting, and accommodates larger shaft sizes.

Features and Specifications of Pillow Block Bearing Units

- Permissible Misalignment: Designed to accommodate varying degrees of static misalignment, essential for ensuring smooth operation and longevity. Permissible values vary based on the need for relubrication and unit type, with typical limits ranging from 1°to 5°.

- Load Handling: Capable of supporting both dynamic and static loads, making them suitable for a wide range of applications. Pressed steel housings generally have a lower load carrying capacity compared to cast iron or stainless steel housings.

- Temperature Limits: Operating temperature ranges are determined by housing material, bearing cage, seals, end covers, and lubricants. Suitable for standard industrial environments, with options available for high-temperature applications.

- Permissible Speed: Operating speeds are subject to limitations based on seal design and shaft tolerances. Bearings with set screws or eccentric locking collars have permissible speeds influenced by the shaft tolerance.

- Axial Displacement Design: Suitable for applications with small axial displacements. In cases of larger displacements, bearing units with set screw locking and appropriate shaft modifications can be used.

Applications of Pillow Block Bearing Units

Commonly used in agricultural machinery, construction equipment, food and beverage processing, conveyor systems, material handling, and packaging systems. Also suitable for special machinery such as gym equipment and car wash systems.

Lubrication and Maintenance of Pillow Block Bearing Units

Bearings are pre-filled with suitable greases, with options available for specific application needs, including food-grade greases.

Relubrication features and intervals vary based on the operating conditions and bearing type.

Mounting and Dismounting of Pillow Block Bearing Units

Designed for ease of installation and maintenance.

Various locking methods, including set screw, eccentric collar, and adapter sleeve locking, cater to different application requirements.