FAG Bearings

6526 ProductsFAG Deep Groove Ball Bearings

FAG Super Precision Angular Contact Spindle Bearing

FAG Bearing Company Profile

FAG Bearings is a globally recognized brand and a pioneering force in the rolling bearing industry. Established in 1883 in Germany by Friedrich Fischer, the company revolutionized bearing technology with Fischer's invention of a machine for the mass production of high-precision steel balls. As part of the Schaeffler Group since 2001, FAG Bearings maintains a diverse product portfolio ranging from super-precision miniature bearings to large-size bearings. Its products, renowned for their quality and durability, find extensive applications across various sectors including automotive, industrial, and aerospace. With its unwavering commitment to innovation and quality, FAG Bearings has been upholding its prestigious reputation in the industry.

Why is LILY Bearing an Equivalent Replacement for FAG Bearings?

LILY Bearing is considered a viable replacement for FAG Bearings due to the following reasons:

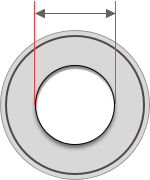

◆ Identical Specifications: LILY Bearing products adhere to the same dimensions and design specifications as FAG Bearings, including inner diameter, outer diameter, width, and load ratings.

◆ Quality and Precision: By utilizing high-standard production processes, LILY Bearing ensures that its products match the performance and durability of FAG Bearings.

◆ Reputable Brand and Reliability: With proven reliability and quality in various practical applications, LILY Bearing enhances customer confidence in its products as effective replacements for FAG Bearings.

◆ Machinery Compatibility: LILY Bearing meets specific machinery requirements, meaning any bearing from LILY that matches the required specifications can be installed as a replacement for FAG Bearings.

◆ Wide Product Range: LILY Bearing provides a diverse array of bearing types and sizes, simplifying the process for customers to find a suitable replacement for FAG Bearings based on their unique needs, such as Super Precision Angular Contact Spindle Bearings, Deep Groove Ball Bearings, etc.

What Are Our Advantages Over FAG Bearings?

While FAG Bearings has a longstanding reputation in the bearing industry, LILY Bearing offers a range of advantages that can make it an attractive choice for customers. Here are some key benefits:

◆ State-of-the-Art Manufacturing: LILY Bearing operates a modern manufacturing facility in Shanghai, utilizing cutting-edge technology and stringent quality control measures to produce superior bearings.

◆ Competitive Pricing: LILY Bearing often provides products at a more affordable price point, offering high-quality alternatives to brands like FAG Bearings.

◆ Easy Cross-Referencing: With a comprehensive bearing interchange chart, customers can easily find Lily Bearing equivalents for bearings from brands like FAG Bearings.

◆ Efficient Supply Chain: LILY Bearing has a reliable and efficient supply chain, ensuring that products are readily available and delivered on time.

◆ Customer Service: LILY Bearing prides itself on attentive and responsive customer service, providing technical support and quick response times to meet customer needs.

These benefits highlight LILY Bearing's dedication to providing high-quality, cost-effective bearing solutions without compromising customer service or product performance.

What are the Application Areas of Lily's FAG Alternatives?

LILY Bearing's FAG alternatives are used across various sectors due to their high performance and reliability. Key applications include:

◆ Automotive: For engines, transmissions, and wheel hubs.

◆ Aerospace: In aircraft engines, auxiliary power units, and landing gear.

◆ Industrial Machinery: In heavy machinery like conveyors, electric motors, and pumps.

◆ Medical Equipment: High precision devices such as MRI machines and surgical robotics.

◆ Renewable Energy: In wind turbines and solar tracking systems.

◆ Robotics and Automation: For precision operation in robotic systems and automated production lines.