What Are Dental Bearings?

Dental bearings are specialized components crucial to the functionality of dental handpieces. Commonly encountered during teeth cleaning or extraction procedures at dental clinics, these bearings are the cornerstone of modern dental tools. Therefore, they are usually called “Dental Handpiece Bearings”.

The Composition and Functionality of Dental Bearings

Materials and Construction

Our company produces dental drill bearings with superior craftsmanship. Innovative materials are selected for both ring and cage constructions, promoting a longer lifespan even with repeated sterilization. These materials are not only wear-resistant but also minimize the need for frequent maintenance, offering cost savings throughout the bearing's lifecycle.

- The inner and outer rings are crafted from refined stainless steel (9Gr18), offering robustness and durability.

- For the balls, we use either the same high-grade stainless steel or non-metallic superhard ceramic (Si3N4), known for its excellent wear resistance.

- The cages are made from high-strength, low-abrasion, self-lubricating materials like polyimide or 80-120 phenolic cloth bakelite, ensuring smooth operation.

Impressive Speed and Efficiency

Dental bearings must withstand the rigors of dental procedures. Engineered for extreme environments, our bearings excel in performance, designed to operate smoothly at high speeds of up to 350,000 to 400,000 rpm under air pressure of 200-250 Kpa. This high speed is pivotal for the effective cleaning of teeth, making dental procedures more efficient and less time-consuming. The low operating noise and friction also contribute to a comfortable experience for patients.

Optimized for Comfort and Efficiency

Our dental bearings are finished to exacting standards, aiming for low friction which, in turn, keeps operating temperatures down. This meticulous attention to detail ensures a more comfortable experience for both dental professionals and patients.

Longevity and Precision Standards

Durability

Under normal usage conditions, these dental bearings have a working life of over six months, which is a testament to their quality and durability.

Manufacturing Precision

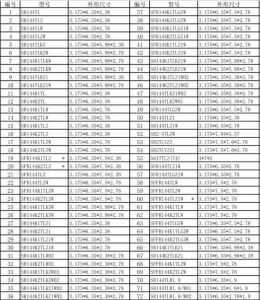

Our high-speed dental bearings are manufactured to meet P4 tolerance levels as per the national standard GB/T307.1-94. This precision ensures compatibility with various models of dental handpieces globally, including renowned brands like NSK in Japan, W & H in Austria, Bein Air in Switzerland, Lares in Germany, KaVo in Germany, FARO, Beijing, Shanghai, Northwest Plant, Midwest, Adec, Yushida Yoshida, Siemens Siemens, Star and other brands of high-speed dental turbomachines. Below are some bearing part numbers of our dental bearings for you to choose.

Installation and Maintenance Guidelines

Installation Precautions

- When the dental drill bearing is installed, the matching interference between the internal control of the bearing and the shaft is the best 0~2μm.

- The circular deviation of the shaft should be less than 2μm.

- The force that presses the shaft into the inner hole of the bearing should directly act on the inner ring of the miniature bearing, and not through the steel ball or the ring groove sleeve, so as not to damage the bearing accuracy.

- After installing a pair of bearings on the turbine, clean the turbine and bearings before putting them into the machine head, and then drip lubricating oil (the cleaning fluid cannot use acetone or ethanol).

Axial Preload

When installing the dental drill bearing into the handpiece, a certain axial preload (1~2N) should be applied to a pair of bearings to obtain ideal high-speed performance.

Commitment to Exceptional Quality

Hygiene and Precision Standards

Every dental bearing is assembled, tested, and packaged in controlled environments to meet the highest hygiene and cleanliness standards. We adhere to international tolerance standards, ensuring each bearing is crafted for ultimate precision.

Design and Testing

Our approach to design is flexible, allowing for compact, lightweight solutions with integrated features as needed, while not compromising on the thorough development and testing process. Rigorous dedicated test rigs confirm that each dental bearing meets specific performance criteria.

Manufacturing Excellence

Innovative Production Facilities

Our manufacturing processes are carried out in state-of-the-art facilities, where advanced R&D, testing, and quality assurance programs are the backbone of our operations. Continuous improvement is our mantra, embedded in everything we do.

Noise Testing and Manufacturing Versatility

We guarantee that all of our dental bearings are 100% noise tested to ensure quality and performance. Our manufacturing approach is both fast and flexible, enabling us to cater to a wide range of customer requirements in terms of quantity without compromising on quality.

Value and Performance

The combination of performance advantages and competitive pricing positions our dental bearings as an exceptional choice for those seeking quality without excessive cost.

Keep Learning