Cancel

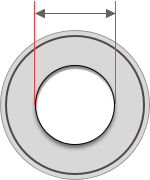

Bore Dia

Ring Material

Outer Dia

Width

High Temperature Bearings

4098 ProductsAlloy Steel Material

Ceramic Material

What are High Temperature Bearings?

High temperature bearings, (also known as high-temperature resistant bearings or extreme temperature bearings), are specialized types of bearings designed to operate in environments with elevated temperatures. These bearings are engineered to withstand heat, making them ideal for applications in industries such as aerospace, automotive, steel, glass manufacturing, and more, where extreme temperatures are encountered.

Features of High Temperature Bearings

- Material Composition: Our high temperature bearings are made from materials with excellent thermal stability and resistance to deformation at elevated temperatures. Common materials include high-quality stainless steels, special heat-resistant alloys, and advanced ceramics.

- Lubrication: Lubrication is crucial for bearings, especially in high-temperature conditions. Our high temperature bearings are often equipped with specially formulated lubricants that can withstand extreme heat and provide reliable lubrication to reduce friction and wear.

- Cage Materials: The cage, also known as the bearing retainer, holds the rolling elements in place. High temperature bearings use cage materials that can withstand the heat without deforming or deteriorating.

Benefits

- Durability: High temperature bearings are designed to maintain their structural integrity and performance even in extreme heat. They offer increased reliability and longevity compared to standard bearings when operating at elevated temperatures.

- Reduced Downtime: By using high temperature bearings, industries can reduce downtime caused by bearing failures due to overheating, leading to enhanced productivity and efficiency.

Why Choose LILY Bearing for High Temperature Bearings?

At LILY Bearing, we offer a wide range of high-quality high temperature bearings, meticulously crafted to withstand extreme temperature conditions. Our bearings are sourced from reputable manufacturers and undergo rigorous testing to ensure excellent performance and reliability.

Order Prompt

The order is added successfully. You can click order to pay or view