SR2A 2rs

| Part Number | SR2A 2rs |

| System of Measurement | Inch |

| Bearing Type | Ball |

| For Load Direction | Radial |

| Construction | Single Row |

| Inner Ring Type | Standard |

| Seal Type | Sealed |

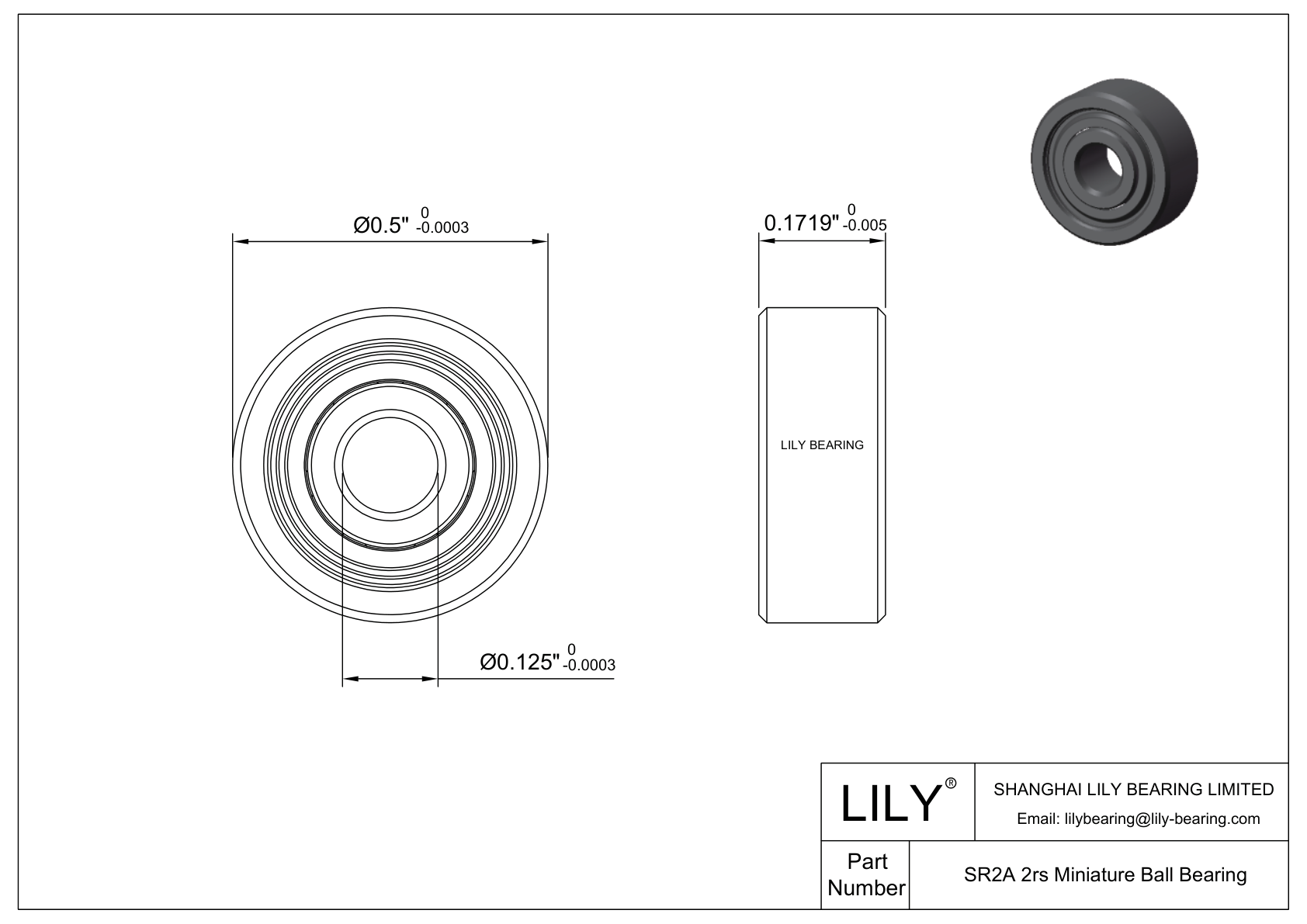

| Bore Dia | 0.125" |

| Bore Dia Tolerance | -0.0003" to 0" |

| Outer Dia | 0.5" |

| Outer Dia Tolerance | -0.0003" to 0" |

| Width | 0.1719" |

| Width Tolerance | -0.005" to 0" |

| Ring Material | 440C Stainless Steel |

| Ball Material | 440C Stainless Steel |

| Cage Material | 300 Series Stainless Steel |

| Shield Material | Nitrile Rubber |

| Dynamic Radial Load | 110 lbf |

| Static Radial Load | 37 lbf |

| Max Speed (X1000 rpm) | 47.7 |

| Lubrication | Required |

| Shaft Mount Type | Press Fit |

| Temperature Range | -86 to 230 °F |

| ABEC Rating | ABEC1 (Available in ABEC3/5/7) |

| Radial Clearance Trade No | MC3 (Available in MC1/2/4/5/6) |

| Radial Clearance | 0.00008" to 0.0005" |

| RoHS | Compliant |

| REACH | Compliant |

| Ball Dia | 0.06252" |

| Ball Qty | 7 |

| Weight | 3.3 g |

Design Features of SR2A 2rs Bearing

SR2A 2rs Bearing offers dependable and efficient performance in industrial applications where space is at a premium. SR2A 2rs bore dia is 0.125". Its out dia is 0.5". SR2A 2rs ball material is 440C Stainless Steel. Its seal type is Sealed. This bearing boasts high-speed capabilities, low friction, and minimal noise levels, ensuring optimal performance. Built to meet industry standards for precision and durability, it is an ideal choice for a variety of compact-space applications in diverse industries.

Applications of SR2A 2rs Bearing

SR2A 2rs Bearing finds applications in various industries that require high precision and compact design, such as medical devices, robotics, and aerospace technology. It is also used in computer hard drives, motors, and instrumentation equipment. Its small size and efficient performance make it a popular choice for industries where space is limited but high precision is essential.

Maintenance and Troubleshooting Tips of SR2A 2rs Bearing

To ensure optimal performance and longevity of SR2A 2rs Bearing, regular maintenance is necessary. Inspect the bearing frequently for any signs of damage, wear, or contamination. Clean it with a non-corrosive solvent and dry it thoroughly before lubrication. If any damage or excessive wear is detected, replace the bearing immediately. In case of any issues with the application, troubleshoot to ensure the bearing is being used within its designed parameters.

})