FR0

| Part Number | FR0 |

| System of Measurement | Inch |

| Bearing Type | Ball |

| For Load Direction | Radial |

| Construction | Single Row |

| Inner Ring Type | Standard |

| Seal Type | Open |

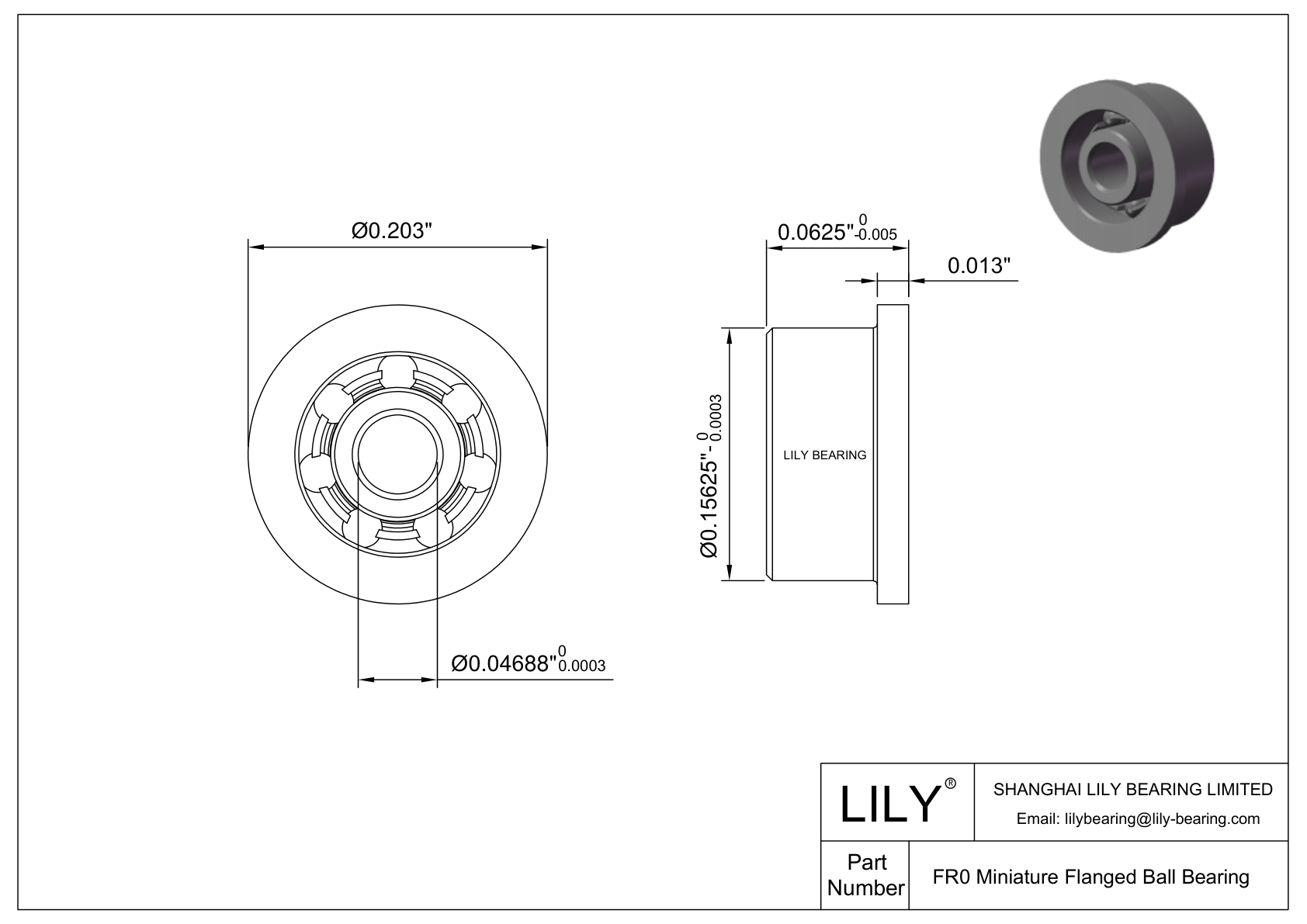

| Bore Dia | 0.04688" |

| Bore Dia Tolerance | -0.0003" to 0" |

| Outer Dia | 0.15625" |

| Outer Dia Tolerance | -0.0003" to 0" |

| Width | 0.0625" |

| Width Tolerance | -0.005" to 0" |

| Flange Outer Dia | 0.203" |

| Flange Thickness | 0.013" |

| Ring Material | Chrome Steel |

| Ball Material | Chrome Steel |

| Cage Material | 300 Series Stainless Steel |

| Dynamic Radial Load | 21 lbf |

| Static Radial Load | 6 lbf |

| Max Speed (X1000 rpm) | 110 |

| Lubrication | Required |

| Shaft Mount Type | Press Fit |

| Temperature Range | -86 to 230 °F |

| ABEC Rating | ABEC1 (Available in ABEC3/5/7) |

| Radial Clearance Trade No | MC3 (Available in MC1/2/4/5/6) |

| Radial Clearance | 0.00008" to 0.0005" |

| RoHS | Compliant |

| REACH | Compliant |

| Ball Dia | 0.02358" |

| Ball Qty | 7 |

| Weight | 0.12 g |

Design Features of FR0 Bearing

FR0 Bearing is designed for applications that require high-speed and reliable operation in small spaces. FR0 bore dia is 0.04688". Its out dia is 0.15625". FR0 ball material is Chrome Steel. Its seal type is Open. This bearing features a flanged design that facilitates easy installation and alignment.

Applications of FR0 Bearing

FR0 Bearing is Ideal for use in dental handpieces, electric motors, Robotics Industry, Motors, Flow Meters, Medical Instruments, Vacuum Pumps, Robotics Industry, Crossbow, Food & Beverage Industry, Anemometer, Clocks, Instrumentation, Fishing reel, ATMs & Card Readers and other precision equipment where space is limited and high speeds are required.

How to Install and Maintain FR0 Bearing for Optimal Performance

The performance and lifespan of FR0 Bearing depend on proper installation and maintenance. Along with ensuring a proper fit and alignment during installation and avoiding damage with appropriate tools, it's vital to consider factors such as selecting compatible lubricant, determining the frequency of lubrication, proper handling and storage, regular inspections, and prompt replacement of any worn or damaged bearings. By taking these proactive measures, you can ensure the optimal performance and longevity of your FR0 Bearing.

})