Cancel

71918 CE/P4A

Price $ 1112.74

Number

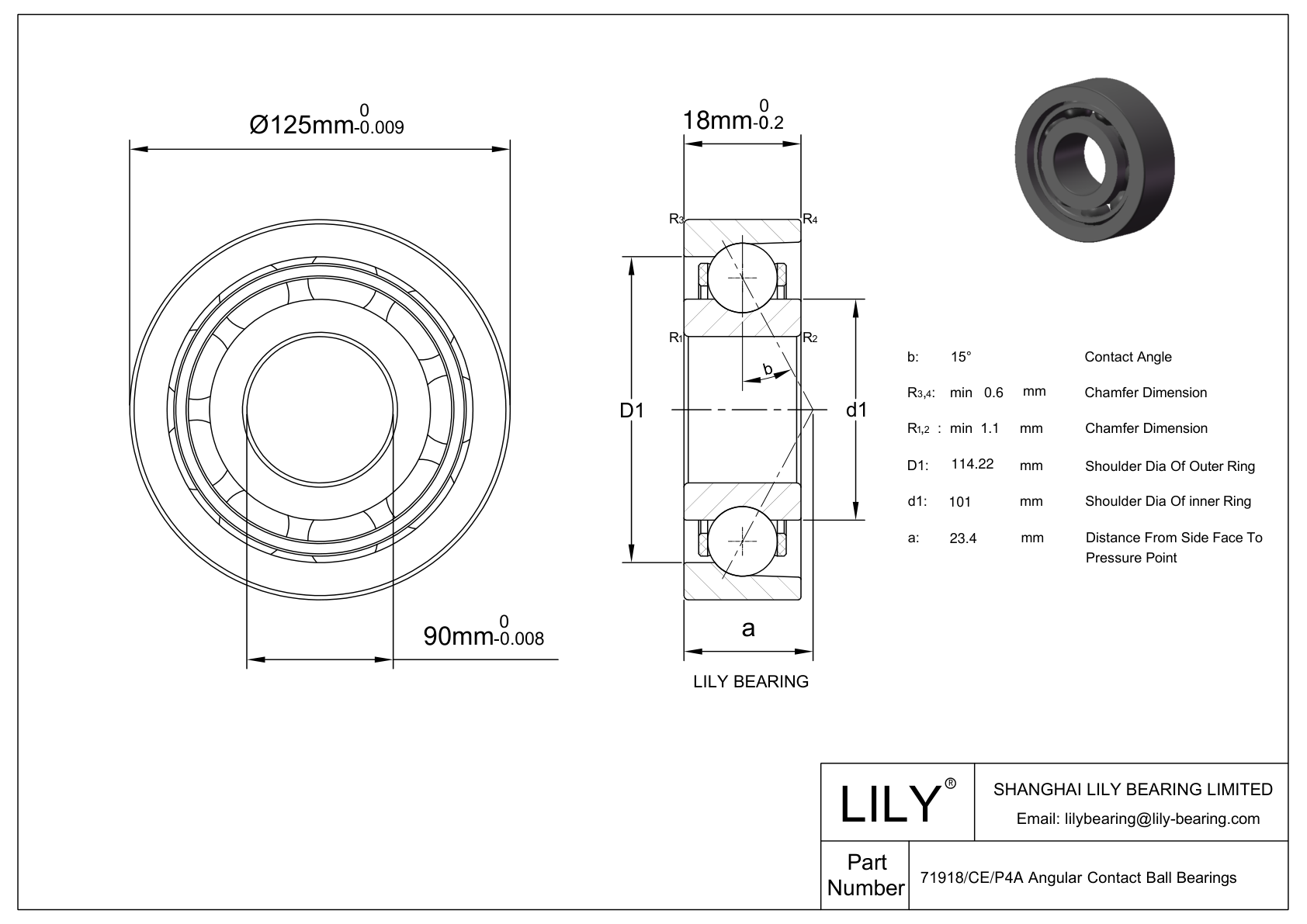

| Part Number | 71918 CE/P4A |

Brand: LILY  | |

Equivalent: SKF |

| System of Measurement | Metric |

| Contact Angle | 15° |

| Seal Type | Open |

| Matched Arrangement | No |

| Preload | Not applicable |

| For Load Direction | Angular Contact |

| Bore Dia | 90 mm |

| Bore Dia Tolerance | -0.008mm to 0 |

| Outer Dia | 125 mm |

| Outer Dia Tolerance | -0.009mm to 0 |

| Width | 18 mm |

| Width Tolerance | -0.2mm to 0 |

| Ring Material | Chrome Steel |

| Ball Material | Chrome Steel |

| Cage Material | Phenolic |

| Dynamic Radial Load | 6908 lbf |

| Lubrication | Lubricated |

| Max Speed (X1000 rpm) | 22 |

| Temperature Range | -30° to 110 °C |

| Static Radial Load | 5400 lbf |

| ABEC Rating | P4 (ABEC-7) |

| Ball Dia | 11.112 mm |

| Ball Qty | 24 |

| Weight | 0.54 kg |

Design Features of 71918 CE/P4A Bearing

The design of 71918 CE/P4A Bearing is a culmination of advanced materials science, mechanical engineering, and precision manufacturing. 71918 CE/P4A bore dia is 90 mm. Its out dia is 125 mm. 71918 CE/P4A width is 18 mm. This bearing is integral in high-speed spindles, precision instruments, and applications where accuracy and speed are critical.

What Benefits Can 71918 CE/P4A Bearing Provide?

- High-Speed Capabilities: Optimized for high rotational speeds with minimal friction and heat generation.

- Exceptional Precision: Manufactured to ultra-precise tolerances, ensuring unparalleled accuracy in operation.

- Enhanced Rigidity and Stability: Offer superior axial and radial rigidity, maintaining stability under varying load conditions.

- Advanced Material Use: Constructed from high-grade materials for durability, wear resistance, and performance at high speeds and temperatures.

- Low Friction and Heat Dissipation: Designed to minimize internal friction, efficiently dissipating heat to prolong bearing life.

What Can 71918 CE/P4A Bearing Be Used for?

71918 CE/P4A Bearing is used in applications where high precision, speed, and reliability are paramount. Their typical uses include:

- Machine Tool Spindles: Essential in CNC machines and precision grinders, where they ensure high-speed, accurate tool performance.

- High-Speed Machinery: Used in equipment requiring high rotational speeds, such as drilling and milling machines.

- Aerospace Components: Crucial in aerospace applications for gyroscopes, actuators, and jet engine components due to their precision and stability.

- Medical Equipment: Employed in high-speed medical devices like dental drills and medical imaging equipment.

- Semiconductor Manufacturing: Used in semiconductor production equipment where precision and speed are crucial for accurate wafer processing.

Recommended Products

})