Quality Inspection and Product Verification

LILY Bearing is equipped with the right tools and expertise to conduct professional quality checks. We offer inspection and verification services for both our own bearings and those supplied by third parties.

The ABMA (American Bearing Manufacturers Association) sets specific guidelines for ball and roller bearings in its document, Tolerance Definitions and Gaging Practices for Ball and Roller Bearings (ABMA-4-1994 (R2013)). This guide provides detailed descriptions of the allowed variations in size, operational precision, and internal space for bearings, referencing standards from both ABMA and ISO. The standard also includes descriptions of the measuring methods commonly used within the bearing industry. However, these standards must be applied by trained professionals with proper equipment.

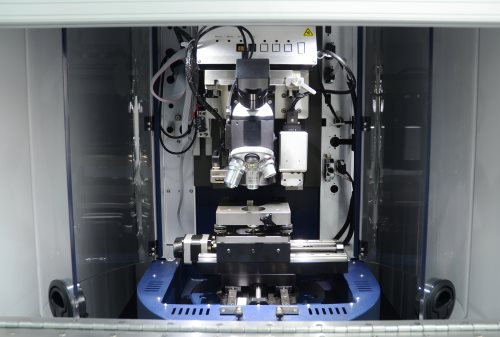

At LILY Bearing, we use video microscopy to check various bearing features, including shape (roundness and radius), surface texture (roughness, Ra), hardness, torque, and digital noise/vibration. This allows us to ensure the bearings meet both external and internal size specifications.

As LILY Bearing is an ISO 9001:2015 certified company, we maintain a tool and gauge calibration system. This tool and gauge calibration system conforms to ANSI/NCSL Z540-1-1994 and ISO/IEC 17025:2005.

To further ensure our products meet our quality standards and specifications, our engineering department works closely with its customers' technical and engineering departments to provide assistance with bearing selection, proper lubricant, mounting, documentation, and elimination of stack-up-tolerance issues.

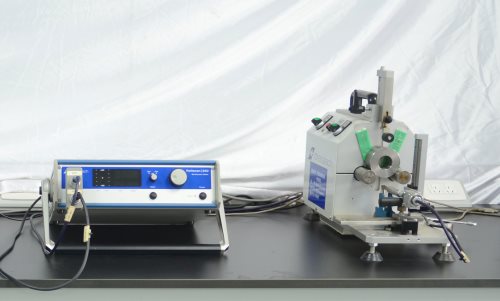

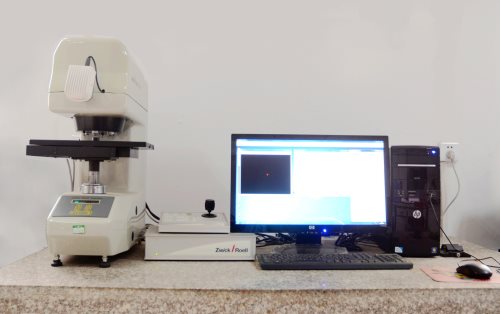

Here is a list of the equipment and verification resources we use:

- Electronic air gauges with a resolution of ten-millionths of an inch

- Vertical comparators and digital amplifiers with a resolution of one-millionth of an inch

- Precision noise tester

- Taylor Hobson Form Talysurf 50 Profile Analyzer

- Large bore noise and vibration analyzer

- Electronic balances

- Digital and dial vernier calipers

- Stereo microscopes with digital video output

- Radial play gauges with a resolution of twenty-millionths of an inch

- Starrett Grade A – Inspection Level Granite Surface Plate

- Inch & Metric, Grade 2, Gauge Block Sets

- One Model 4TTA Wilson Rockwell Hardness Tester

- Miniature and instrument bearing torque tester

- Plug gauges

- Dial indicators

- Digital micrometers