Cancel

GDHHKFBB

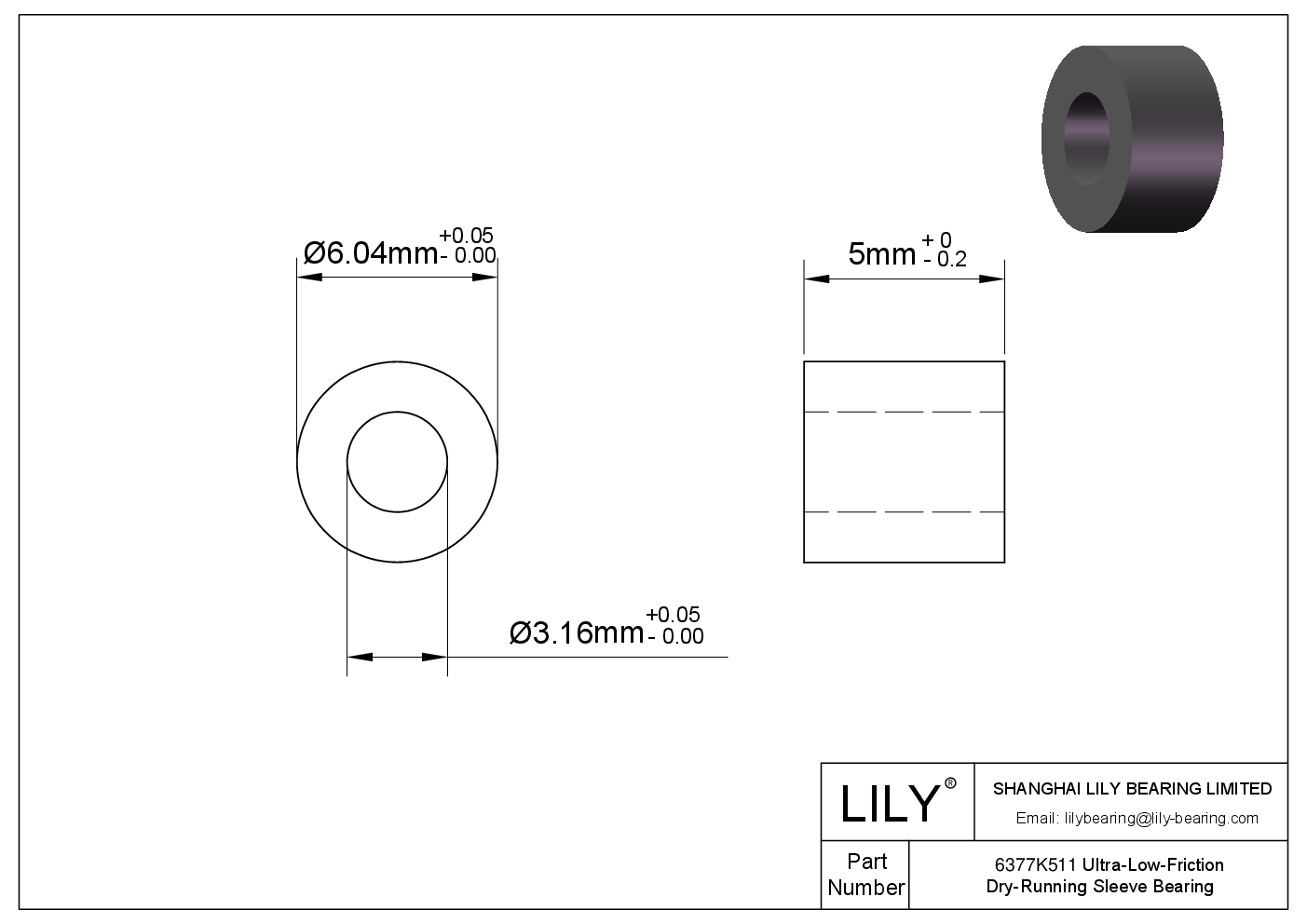

| Part Number | GDHHKFBB |

| System of Measurement | Metric |

| Bearing Type | Plain |

| Plain Bearing Type | Sleeve |

| For Load Direction | Radial |

| For Shaft Diameter | 3mm |

| Bore Dia | 3.16 mm |

| Bore Dia Tolerance | 0 mm to 0.05 mm |

| For Housing ID | 6 mm |

| Outer Dia | 6.04 mm |

| Outer Dia Tolerance | 0 to 0.05 mm |

| Length | 5 mm |

| Length Tolerance | -0.2mm to 0mm |

| Dynamic Radial Load | 47 lbf |

| Static Radial Load | 47 lbf |

| Max Speed (X1000 rpm) | 0.12 |

| Material | Rulon J Plastic |

| Lubrication | Not Required |

| For Shaft Type | Round |

| Shaft Mount Type | Slip Fit |

| Temperature Range | -400° to 550° F |

| RoHS | Compliant |

| REACH | Compliant |

INTERCHANGE

The LILY Bearing part series GDHHKFBB is a potential replacement for these common bearing part numbers.

LILY

MCMASTER

GDHHKFBB