Sign in

New customer? Start here

Cancel

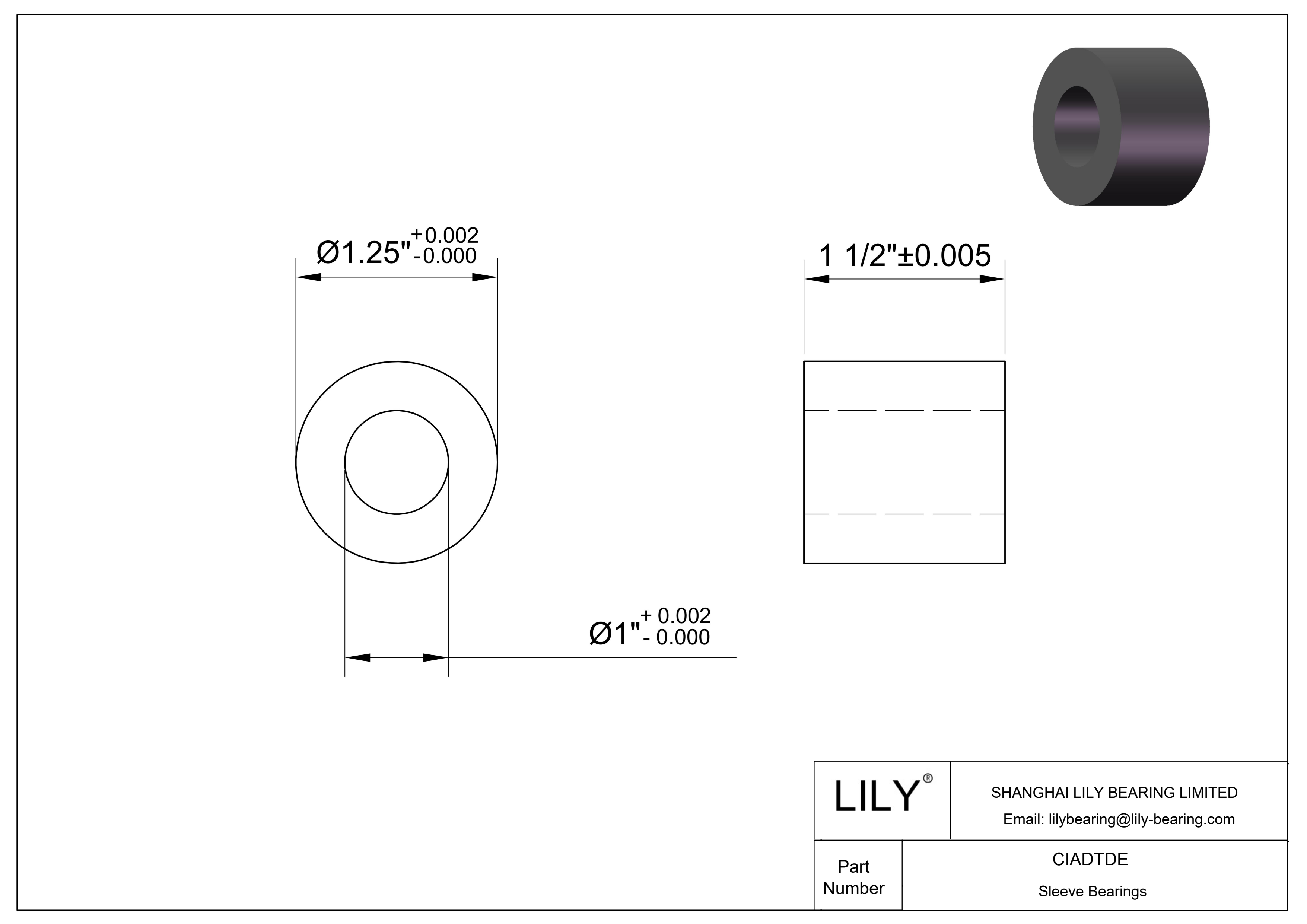

CIADTDE

| Part Number | CIADTDE |

| System of Measurement | Inch |

| Bearing Type | Plain |

| Plain Bearing Type | Sleeve |

| For Load Direction | Radial |

| For Shaft Diameter | 1" |

| Bore Dia | 1" |

| Bore Dia Tolerance | 0" to 0.002" |

| For Housing ID | 1 1/4" |

| Outer Dia | 1.25" |

| Outer Dia Tolerance | 0" to 0.002" |

| Length | 1 1/2" |

| Length Tolerance | -0.005" to 0.005" |

| Dynamic Radial Load | 1050 lbf |

| Static Radial Load | 1050 lbf |

| Max Speed (X1000 rpm) | 0.06 |

| Filler Material | Glass |

| Material | PTFE Plastic |

| Lubrication | Not Required |

| For Shaft Type | Round |

| Shaft Mount Type | Slip Fit |

| Temperature Range | -350° to 500° F |

| RoHS | Compliant |

| REACH | Compliant |

INTERCHANGE

The LILY Bearing part series CIADTDE is a potential replacement for these common bearing part numbers.

LILY

MCMASTER

CIADTDE

2803T34

Design Features of CIADTDE Bearing

CIADTDE Bearing is made from advanced plastics or composites, with optional stainless steel inserts for added strength and resistance to chemicals. The bearing features a self-lubricating PTFE layer for smooth, lubricant-free operation. Precision-finished surfaces reduce friction and wear, and a chemical-resistant coating enhances durability. CIADTDE bore dia is 1". Its outer dia is 1.25". CIADTDE length is 1 1/2". The bearing is crucial for many industrial uses because it is durable, needs no maintenance, and resists harsh chemicals.

What Benefits Can CIADTDE Bearing Provide?

- Self-Lubricating Design: No need for external lubricants, reducing maintenance and preventing contamination.

- Corrosion Resistance: The bearing is made from materials like stainless steel or advanced plastics, so it resists corrosive chemicals.

- High Temperature Tolerance: It can work efficiently in high-temperature environments. It will not break down under these conditions.

- Low Maintenance: Durable and self-lubricating, The sleeve bearing requires less frequent maintenance, reducing downtime and costs.

- Versatile Applications: It is perfect for the food and chemical processing industries. These industries need equipment that stays clean and resists harsh chemicals.

What Benefits Can CIADTDE Bearing Provide?

- Chemical Processing Plants: The bearing can be used in pumps and valves to handle corrosive fluids and prevent chemical damage to the bearings.

- Pharmaceutical Industry: It is used in pharmaceutical equipment to keep operations free from contamination.

- Food and Beverage Industry: It is used in food processing machinery to resist cleaning chemicals and high-pressure washdowns.

- Water Treatment Facilities: The bearing can be applied to filtration systems and pumps to handle chemically treated water.